We will start off with an update to a news item we had last week about a company by the name of Cold Heading Company of Cleveland, Ohio, USA auctioning off some surplus equipment, including a number of heat treat furnaces. We made some predictions about what would happen to the equipment (you can find the details below). So how were our predictions? Almost 100% wrong much to our embarrassment. The small mesh belt line sold for $50,000 USD, the cast link line sold for $65,000 USD with the 2 generators included and the largest line remains on the market. Buyer for both lines was a company by the name of Total Forge of Mexico, a company we know nothing about.

“Roughly 2 years ago, Cold Heading Company closed their Lee Road, Cleveland facility and since that time the equipment (including their large heat treating department) has been sitting idle collecting dust. Tomorrow Thursday, December 6 everything goes to auction and this includes the heat treat department. This consists of an AFC 1500 pounds/hour mesh belt line, an AFC 2500 pounds/hour cast link belt line, an AFC 4,000 pounds/hour mesh belt line and 2 AFC Endo generators-all mid 1990’s vintage and all seeming complete and in reasonable or good condition. Now if we were betting people at “The Monty” this is what we expect will happen; the 1500 and 2500 pound lines will be sold to a scrap dealer, the endo generators will also be scrapped or go for almost nothing and the largest line, the 4,000 pound/hour line we would guess will either be sold or removed from the auction.AFC, the largest atmosphere furnace builder in North America is known as a premium supplier of continuous lines and generators but the reality is that very few people these days want continuous lines smaller than about 3,000 pounds per hour, cast link belt lines have little appeal these days and newer multi retort generators have largely replaced the older style units such as these. We actually hope we are wrong on these predictions as we hate to see top quality, good equipment scrapped but experience tells us this is what we can expect.”

As mentioned some time ago auto parts supplier and captive heat treater Dana in Glasgow, Kentucky closed this year and all the remaining equipment must be removed in the fairly near future. This includes 3 1970’s vintage Surface Combustion, gas fired 3 row pusher furnaces. The furnaces range in condition from very good to fair. Nothing wrong with the equipment and I would hate to see them scrapped but there is not a large market for used pusher furnaces. Jorgenson Forge out in Washington state is another facility which has closed and has surplus heat treating equipment, in this case some carbottom furnaces. The on line auction will go until December 11. One of the furnaces available is shown below.

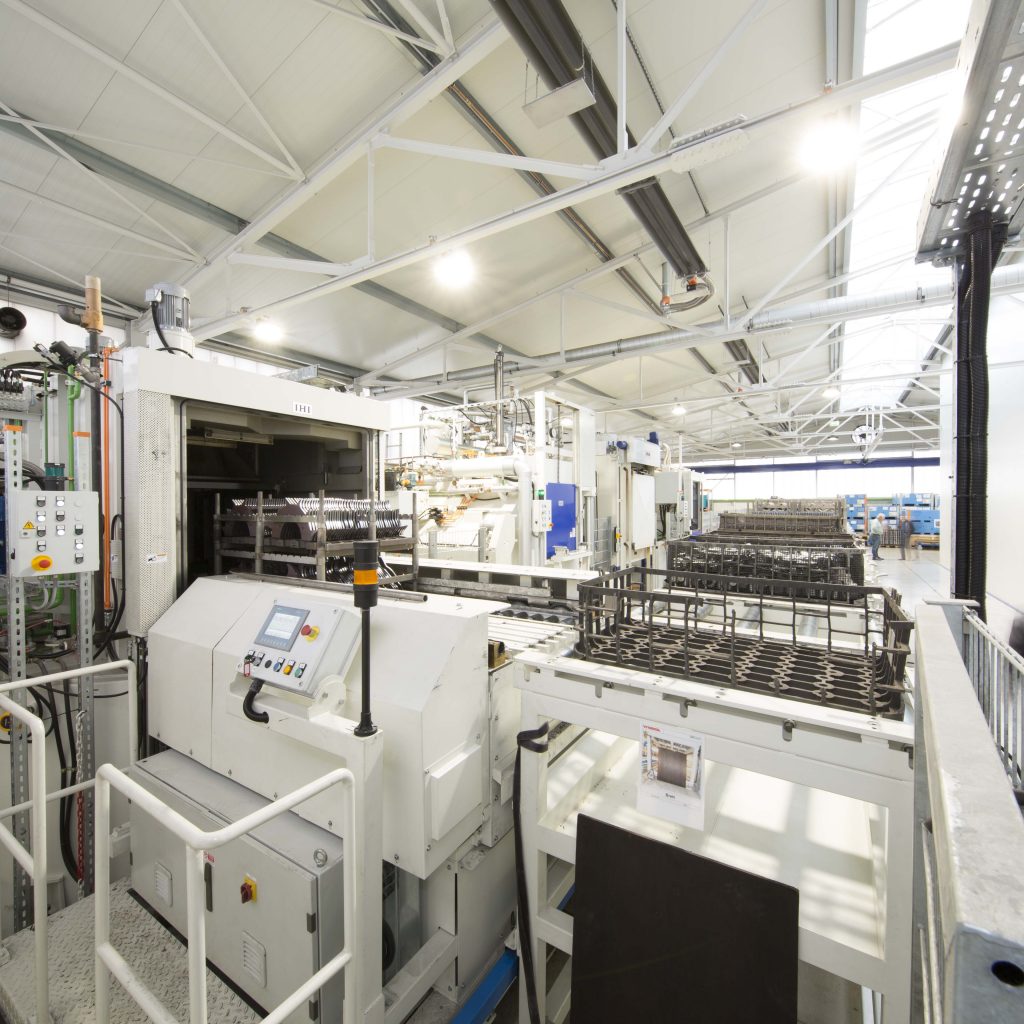

Let’s move to Germany where we see that the VTN Group is adding LPC Capacity. VTN in Germany is a commercial heat treater with 5 locations around the country. Back in November 2015 100% of the shares of the company were acquired by Japan based IHI Corporation meaning that the group now has four companies serving the heat treating and PVD/CVD/PACVD coatings industries; IHI Machinery and Furnace Co., Ltd (IMS), IHI Ionbond AG, IHIHauzer Technocoating B.V. and VTN Group. At the VTN, Witten-Herbede plant the existing fully automatic LPC line was just expanded by adding a new IHI LPC furnace. Georg Niessen, the CEO has this to say; “We really believe in this technology as a future alternative to chamber furnaces and we will be adding the new IHI LPC systems in the Wilthen plant (East German) and Freiburg plant (South Germany. By this we will meet the high and increasing customer demands in the future. The big advantages we see are the high uniformity during carburizing, enhanced cleanliness of products,the elimination of inter-granular oxidation layer and carburizing temperatures up to 1,050° C. The environmental friendliness is also trend-setting, there are no emissions or direct CO2 emissions. The systems used at VTN have a maximum capacity of 1,000 kg and are thus fully suitable for economic mass production.”

To this news item we will add that IHI is one of the largest manufacturers in the world when it comes to low pressure carburizing systems and to date has installed more than 300 systems with acetylene and oil quenching. The VTN Group has 5 locations around Germany with over 300 employees making them a darn big commercial heat treater. The company services most industries and has NADCAP certification. The photo below shows the brand new IHI low pressure carburizing furnace at the Witten plant.

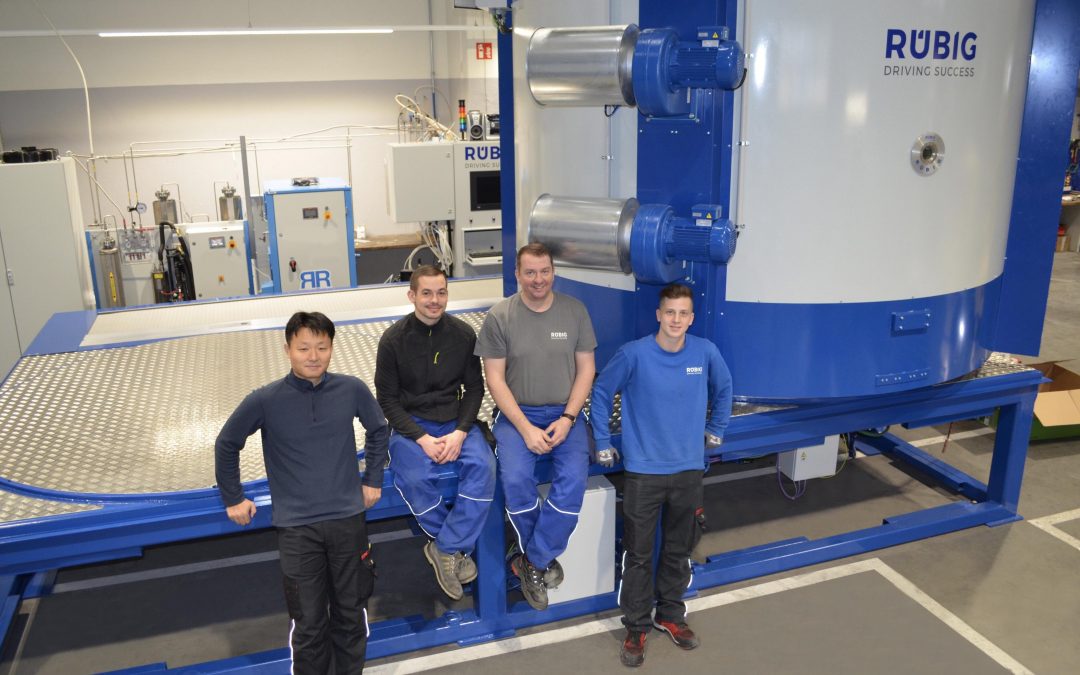

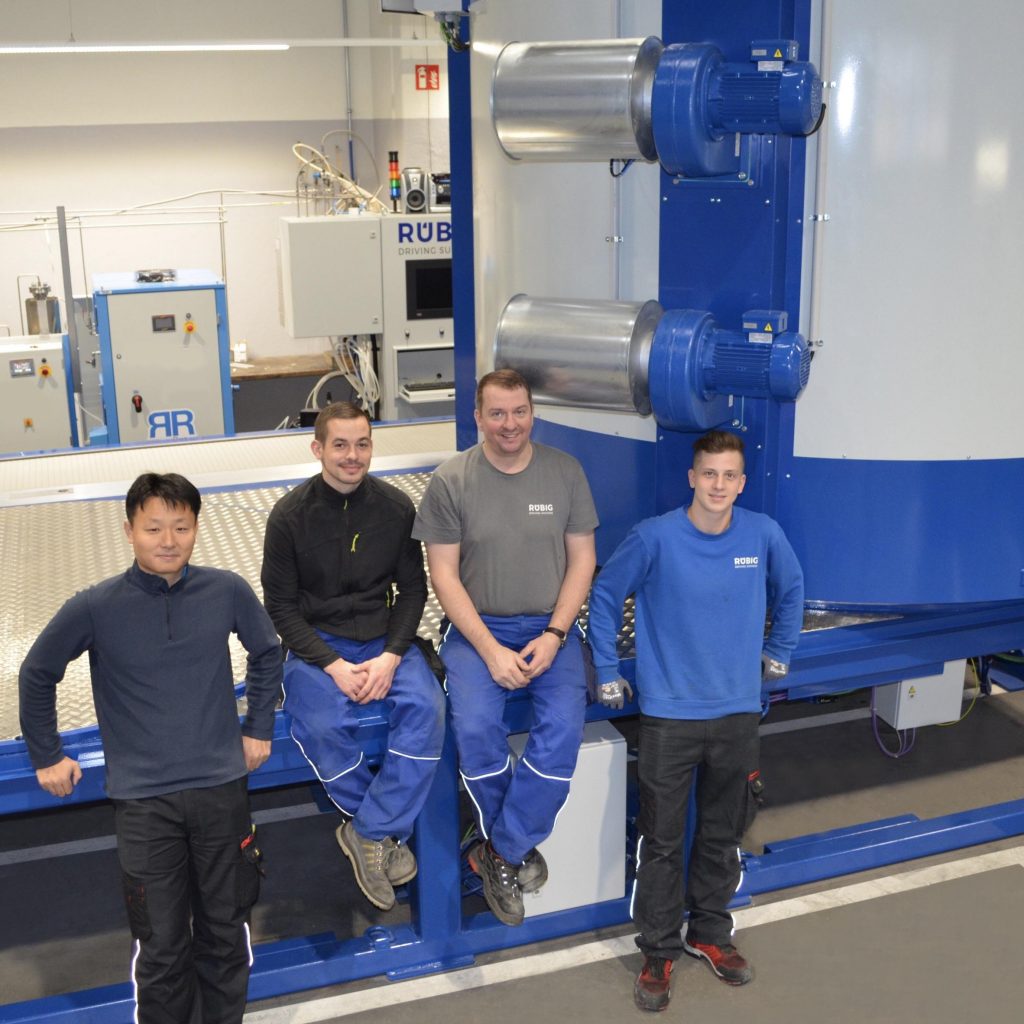

This really cool picture shows the largest Plasma (Ion Nitrider) which Rubig of Wels, Austria has ever built. If it is the largest that Rubig has ever made then that means it is one of the largest built by anybody.

And to round things out we see that commercial heat treater Pontus in the Netherlands is now NADCAP certified, always a challenge but always a good thing. “Pontus received Nadcap accreditation for demonstrating their ongoing commitment to quality by satisfying customer requirements and industry specifications.”Achieving Nadcap accreditation is not easy: it is one of the ways in which the aerospace industry identifies those who excel at manufacturing quality product through superior special processes. Companies such as Pontus work hard to obtain this status and they should be justifiably proud of it,” said Joe Pinto, Executive Vice President and Chief Operating Officer at the Performance Review Institute. “PRI is proud to support continual improvement in the aerospace industry by helping companies such as Pontus be successful and we look forward to continuing to assist the industry moving forward.”