ECM USA discusses Robotics in the Heat Treat Industry

Recently “The Monty Heat Treat News” had a series entitled; “Robotics & Automation in the Heat Treat Industry”-this series can be found at the links below-each of which features a different company.

“Robots in the Heat Treatment Industry-Wallwork Group”

“Robots in the Heat Treatment Industry-Thermetco”

“Robots in the Heat Treatment Industry-Fendt Tractors”

“Robotics & Automation in the Heat Treat Industry- Tecno-ingranaggi S.r.l.”

We are very fortunate that Mr. Dennis Beauchesne, General Manager of ECM USA reached out with these thoughts and comments.

We are very fortunate that Mr. Dennis Beauchesne, General Manager of ECM USA reached out with these thoughts and comments.

“Hello Gord, I really enjoyed speaking with you about the additions you have recently had about robotics on “The Monty “. In that conversation we talked about how the heat treat industry is finally starting to look at advanced automation with robotics as part of the answer to labor issues or shop efficiency. I can confidently say, Gord, the era of robotics in heat treat is now and here to stay!

“Hello Gord, I really enjoyed speaking with you about the additions you have recently had about robotics on “The Monty “. In that conversation we talked about how the heat treat industry is finally starting to look at advanced automation with robotics as part of the answer to labor issues or shop efficiency. I can confidently say, Gord, the era of robotics in heat treat is now and here to stay!

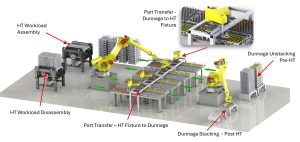

FORD coined the phrase “Have you driven a FORD lately?” Well, we now ask “Have you looked at integrating heat treat robotics lately?” Let it be known industry wide – ECM can integrate robotics and advanced automation on new or existing furnace installations of any manufacturer.

FORD coined the phrase “Have you driven a FORD lately?” Well, we now ask “Have you looked at integrating heat treat robotics lately?” Let it be known industry wide – ECM can integrate robotics and advanced automation on new or existing furnace installations of any manufacturer.

ECM has included robotics in our proposals now for over 7 years. This experience comes from our ECM Robotics division that has been very active in the Semiconductor and Solar Panel (PV) business – with over 20 years experience and over 100 installations!

Since then, I am amazed at how fast the technology has grown! Not only in the robot mechanisms but the learning software working together with vision systems. Even with the systems we have installed in North America for vacuum carburizing (LPC), technology has significantly changed in just a few years. The transition from 2D to 3D vision has been innovative to say the least. This now allows robots to further integrate with heat treaters’ needs.

Since then, I am amazed at how fast the technology has grown! Not only in the robot mechanisms but the learning software working together with vision systems. Even with the systems we have installed in North America for vacuum carburizing (LPC), technology has significantly changed in just a few years. The transition from 2D to 3D vision has been innovative to say the least. This now allows robots to further integrate with heat treaters’ needs.

I have had numerous conversations with heat treaters stating, “we could never use robots – we have too many different parts each day” or “most of my parts come in bins and the robot would never be able to pick up the pieces in different orientations”. I can now tell them that these situations are possible with self-teach modes and 3D vision to look at the bin and understand how to approach a part to pick it and even understand where it will be loaded in a fixture or basket. And as far as multiple types of parts per day- this is also possible without hours of special programming. To see ECM Robotics in action and integrated on an ECM NANO vacuum furnace installation, view our newest customer testimonial video with SEW-EURODRIVE in Lyman, SC:

I have had numerous conversations with heat treaters stating, “we could never use robots – we have too many different parts each day” or “most of my parts come in bins and the robot would never be able to pick up the pieces in different orientations”. I can now tell them that these situations are possible with self-teach modes and 3D vision to look at the bin and understand how to approach a part to pick it and even understand where it will be loaded in a fixture or basket. And as far as multiple types of parts per day- this is also possible without hours of special programming. To see ECM Robotics in action and integrated on an ECM NANO vacuum furnace installation, view our newest customer testimonial video with SEW-EURODRIVE in Lyman, SC: