German Auto Parts Supplier Hirschvogel Group Commissions Furnace Line

Back in March of 2025 it was announced that auto parts supplier “Hirschvogel” would be installing a new, automated heat treat line provided by “Aichelin Group” of Austria (the original news item can be found below).

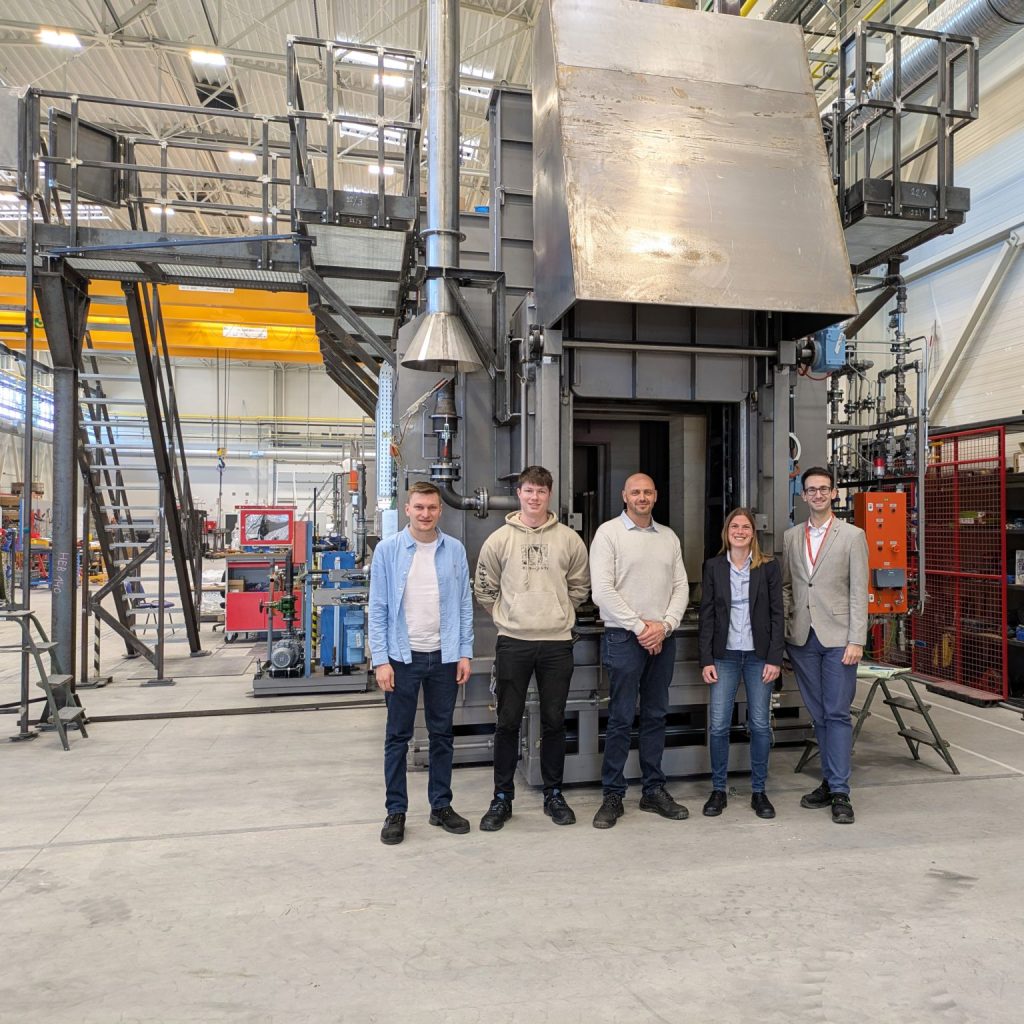

Recently the line entered full production with the ability to 𝗽𝗿𝗼𝗰𝗲𝘀𝘀 𝘂𝗽 𝘁𝗼 𝟭,𝟬𝟬𝟬 𝗸𝗴 𝗼𝗳 𝗱𝗶𝗳𝗳𝗲𝗿𝗲𝗻𝘁𝗶𝗮𝗹 𝗴𝗲𝗮𝗿𝘀 𝗳𝗼𝗿 𝗲𝗹𝗲𝗰𝘁𝗿𝗶𝗰 𝘃𝗲𝗵𝗶𝗰𝗹𝗲𝘀 𝗽𝗲𝗿 𝗯𝗮𝘁𝗰𝗵. This photo shows the completed line;

“MARCH 2025 POST; German Auto Part Supplier to Receive New Furnace System; “Hirschvogel Group” of Germany is known as one of the world’s largest manufacturers of forged and machined steel and aluminum components, primarily for the automotive industry-as such they have a great deal of in house heat treating capacity.

The company recently accepted a double-flow chamber furnace (heating capacity: 365 kW), a preheating furnace, an endogas generator (endomat) & comprehensive peripheral equipment. All of the equipment is being provided by “Aichelin Group” of Austria and was built in their “Bosio” facility in Slovenia.

“The new, electrically heated system has Kanthal heating elements which stands for efficiency, durability and future-proofing. The furnace handles up to 2,200 kg (roughly 5,000 pounds) per batch.”

Earlier this year Mr. Gord Montgomery of “The Monty Heat Treat News” visited the “Bosio” facility in Slovenia and the result was this summary “Furnace Builder Shows Off Newest Facility” . Interestingly enough if you look closely at the photos in our original article you can see this furnace during final assembly along with members of the “AIchelin” team including the CEO of the company Mr. Christian Grosspointer.

For more information about “Hirschvogel Group” and their heat treating capabilities we would suggest this story from “The Monty”. “Hirschvogel Automotive Group-In House Heat Treating”