Stable Nickel Pricing Means Stable Fixture Pricing

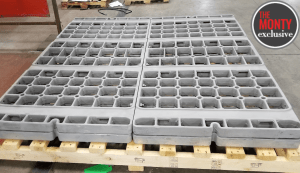

While a number of factors are in play when determining the cost of heat treatment alloy components such as base trays, fixtures, radiant tubes, fans and muffles one component is far and away the determining factor in the cost of alloy items-that factor is of course nickel.

While a number of factors are in play when determining the cost of heat treatment alloy components such as base trays, fixtures, radiant tubes, fans and muffles one component is far and away the determining factor in the cost of alloy items-that factor is of course nickel.

The reason is that nickel quite often is the main component by % of any of the various elements which go into a casting (the same holds true for fabricated items such as wire rod baskets also). The “Nickel Institute” has a very interesting article about the various grades of heat resistant castings entitled; “Heat and Corrosion Resistant Castings; Their Engineering Properties and Applications”. https://nickelinstitute.org/me

The article is particularly interesting in that lays out in clear detail where the various compositions should be used. Page 4 breaks down the alloy composition and shows that nickel content can range from 18-22% in HK material to 64-68% in HX material, both reasonably common materials in the heat treat industry.

With those figures in mind it becomes clear that fluctuations in nickel pricing will have an immediate effect on the price of heat resistant materials used by all heat treaters. This brings us back to our original point, nickel pricing at least for the time being is relatively constant which means stable alloy costs.

Did you like this article? Click here to subscribe to The Monty.

View our recent magazines and podcasts by clicking the following link. https://themonty.com/magazine/