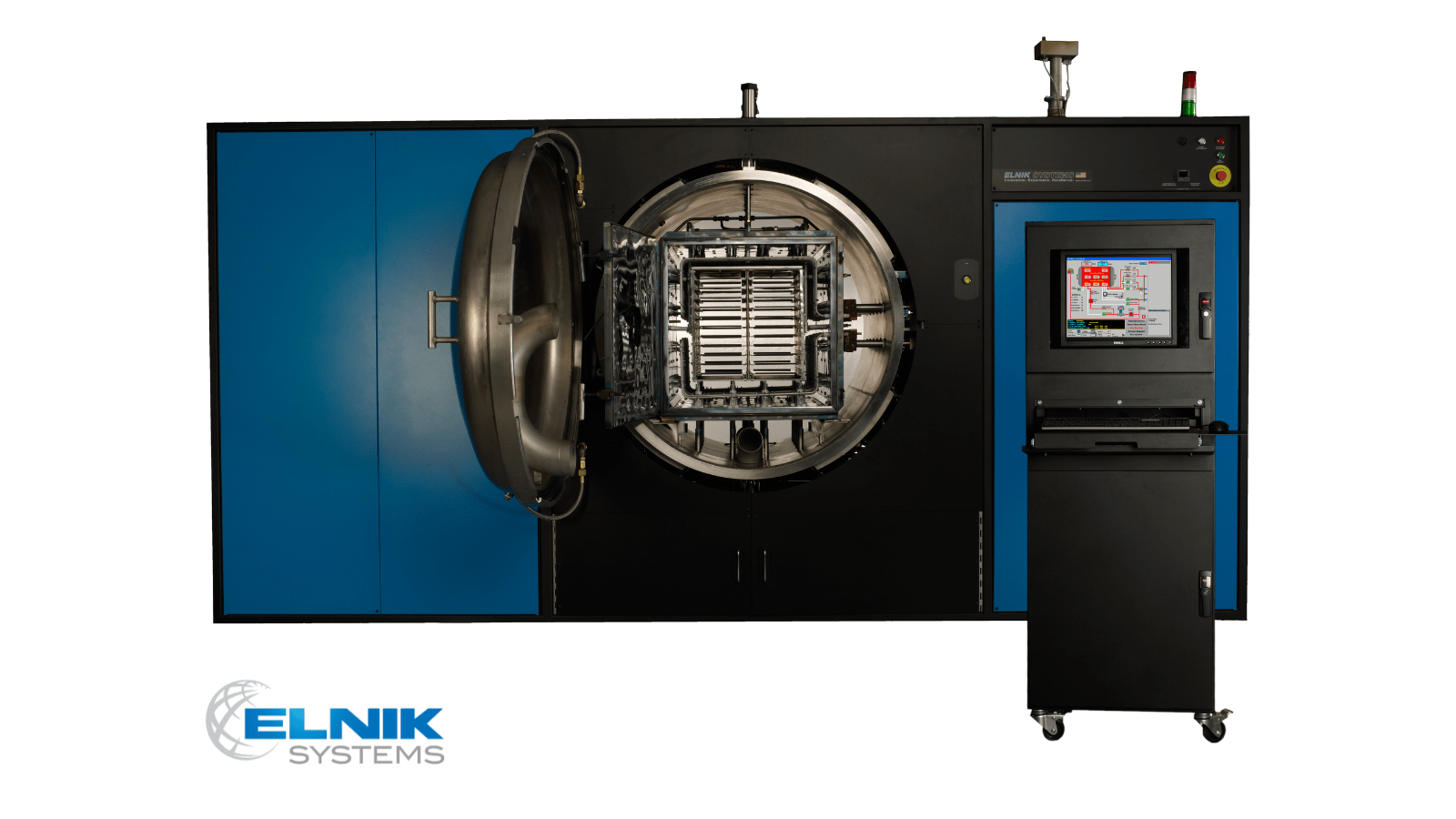

SSI Sintered Specialties Completes Installation of Vacuum Furnace

Earlier this year powdered metal specialists SSI Sintered Specialties announced they had ordered a new vacuum furnace from Elnik, our understanding is that the furnace has now been installed. “With the recent investment in an ELNIK high temperature refractory metal-lined vacuum furnace, SSI Sintered Specialties has announced its commitment to aggressive expansion into new powder metallurgy processes. The vacuum furnace, slated for installation in September 2021, will join a growing fleet of new equipment in SSI’s technology center in Janesville, Wisconsin.

Along with providing customers advanced powder metallurgy processing, this investment positions SSI to immediately target the addition of metal 3D printing to its portfolio and the expansion of its current metal injection molding (MIM) operations. This furnace allows SSI to develop sintering profiles for both technologies, plus its press and sinter processes.

“Adding this sophisticated vacuum furnace to our technology center showcases our commitment to being a customer-centric organization,” said Paul Hauck, Chief Operating Officer at SSI Sintered Specialties. “Investments like this allow us to better serve our customers by helping them solve complex application challenges with the development of new materials and processes.”

Through advanced processes and alloy development, SSI targets the diversification of both its technology portfolio and the markets it serves. SSI will focus on providing high volume powder metallurgy, MIM and metal 3D printing production to the following markets: aerospace, automotive, defense, electronics, industrial, medical, and sports equipment.

Along with processing large powder metal parts, prototypes and pre-production runs, SSI will implement an advanced feedstock material that enables the production of large-sized MIM parts that are greater than 200g. The addition of the vacuum furnace also allows SSI to expand its alloy and material development interests beyond unique variations of stainless-steel alloys, including processing metal-matrix composites and reactive materials such as titanium alloys.

To be at the forefront of the development of new sintering technologies, SSI has proactively added industry-leading talent to support its growing customer base and market diversification. SSI is eager to continue investing in new production capabilities and talented engineering experts as future technology is announced. SSI is actively filling capacity for its advanced press and sinter powder metallurgy, metal injection molding and metal 3D printing processes.

About SSI Sintered Specialties; SSI Sintered Specialties, headquartered in Janesville, Wisconsin, is a diverse engineering company and international supplier of high-performance products through in-house material development and advanced powder metallurgy processes. Our talented team of over 400 technical experts enable our global customer base to lead their industries with new technology that promotes a sustainable future. In our commitment to innovation, we are aggressively pioneering advanced press and sinter powder metallurgy, metal injection molding and metal 3D printing processes to unlock the full potential for material and product development.”