Item # C383 18” Sintering Furnace $39,000 USD

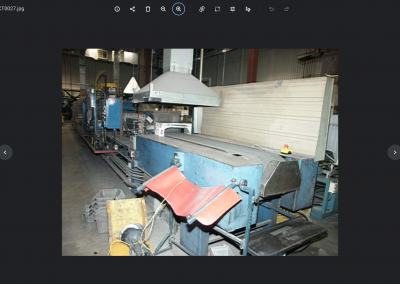

Sinterite 18E-5Z-VC conveyor belt continuous furnace (serial no. 95739) used for sintering of iron, copper, brass, and bronze parts in a controlled, nitrogen and hydrogen atmosphere. The furnace was operational for 13 years, and the Versa-Cool cooling section for the last of those 6 years. It has spent the last 12 years in storage. It is a complete line, including:

- Conveyor belt drive and parts loading area at the entry end of the furnace

- Controlled atmosphere collection hood on both ends

- Two separate, electrically heated chambers (two zones in the first, three zones in the second)

- “D” shaped muffle with reinforcing gussets, with heating elements above and below

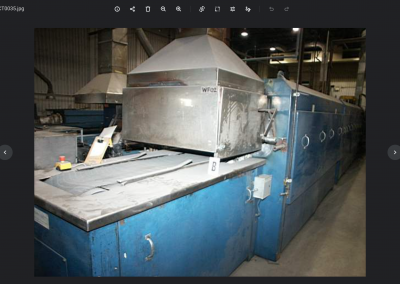

- Versa-Cool cooling section useful for sinter hardening

- Ten additional feet of conventional cooling in 3 sections

- Unloading table and discharge chute at the exit end of the furnace

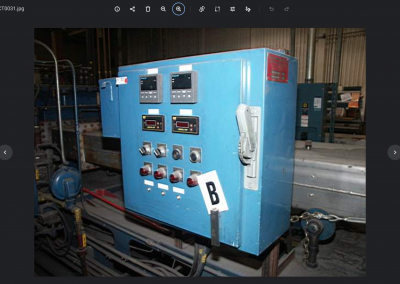

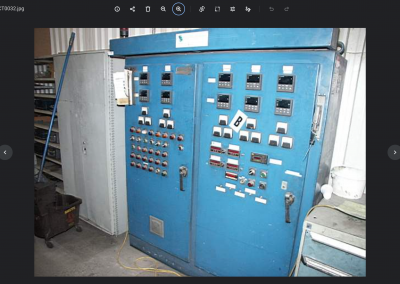

- Flo-meter panel for control of the atmospheric gases

- Panel with full controls for belt speed and temperature (including ammeters)

- Steel mesh conveyor belt

Technical Specifications:

- Conveyor belt width: 18”

- Usable height above belt: 5”

- Heating zone lengths: chamber 1 (pre heat) is 144”, chamber 2 (high heat) is 180”

- Total furnace length (approximate): 70’

- Maximum operating temperature: pre heat is 1800°F, high heat is 2100°F

- Power Requirements: 275 kW, 3 phase, 60 Hz

- Hourly production (weight/hour ratio): 600 lbs/hour

- Conveyor belt speed: up to 10 inches/minute

- Insulation Type: Ceramic Fibre Blanket, Board, Modules, and Fire Brick

- Insulation Thickness: 12” Sidewalls and Roof

- Versa-Cool Length: 130”

- Versa-Cool Area: combined 654 sq. ft. including convective, conductive, and radiant cooling

- Versa-Cool Cooling Rate: as high as 480°F per minute

Asking Price $39,000 USD excluding shipping, installation, and commissioning.