Ben Grammer, Grammer Vacuum Technologies – The Interview

Today we are pleased to be able to offer you this interview with Mr. Ben Grammer of Grammer Vacuum Technologies of Post Falls, Idaho, USA. Ben, I have been rather excited about doing this interview with you as I have known you and your father for many years now, as a matter-of-fact Bob Grammer and I must go back over 20 years now.

Let’s start off talking about the general background of Grammer Vacuum Technologies, when it was founded, where you are located and the territory that you cover.

Yes, Gord, happy to. My dad, Bob Grammer, founded GVT in 1992. We are located near Coeur d’Alene, Idaho (pronounced Core Duh Lane), home to the world’s first and only floating golf green. Our territory is the Greater Northwestern USA, from the Golden Gate Bridge to British Columbia, and from the Pacific Coast to the plains of Colorado.

Because of my background I am very partial to family owned businesses in the heat treat industry. What is your background and what prompted you to take over from your father?

My grandpa was a master tool and die maker who made parts for the first moon landing, so manufacturing runs in the family. Dad ran induction melting furnaces producing titanium, zirconium, and other specialty metals and later worked in sales providing melting and casting furnaces and molybdenum. In high school, I took several sales trips with Dad. The heat treaters were glad to see me tagging along, and several people told me to get a materials engineering degree and then come back and they would hire me on the spot. Realizing that with my Dad’s background I had a head start in materials engineering, and knowing there would be jobs available, I did get the degree (from Washington State). To build some experience with large companies, I worked four years as an ingot casting process engineer at Kaiser Aluminum. Then I joined Dad and spent years soaking up his knowledge. I couldn’t pass up the opportunity to take over his very successful and growing business.

My grandpa was a master tool and die maker who made parts for the first moon landing, so manufacturing runs in the family. Dad ran induction melting furnaces producing titanium, zirconium, and other specialty metals and later worked in sales providing melting and casting furnaces and molybdenum. In high school, I took several sales trips with Dad. The heat treaters were glad to see me tagging along, and several people told me to get a materials engineering degree and then come back and they would hire me on the spot. Realizing that with my Dad’s background I had a head start in materials engineering, and knowing there would be jobs available, I did get the degree (from Washington State). To build some experience with large companies, I worked four years as an ingot casting process engineer at Kaiser Aluminum. Then I joined Dad and spent years soaking up his knowledge. I couldn’t pass up the opportunity to take over his very successful and growing business.

Ben what is your territory like? For instance, a heavy preponderance of captive heat treaters over commercials? Aerospace over automotive? A growing or stagnant heat-treating market?

A lot of aerospace, some medical, some general manufacturing. Lots of knife manufacturers. Not much automotive to speak of. Steady might be a better descriptor than growing, at least overall. We have seen for instance several commercial heat treat shops in Colorado shut down. That said, there is a steady demand for heat treating in the territory. Many aerospace companies have been slow since 2020, but that will turn around.

Over the years I have seen GVT slowly evolve, a process which has been very interesting to watch. However, lets start out with your origins as a manufacturer’s rep firm. Perhaps you could give us some background as to how a rep firm works for those of our readers who are not familiar with independent sales reps.

As with most of life, it is all about who you know. There are two definite sides to the manufacturer’s rep coin. First, we need to know the heat treaters in the area. Second, we need to know the best equipment suppliers in the industry. Then we can help both by introducing them to each other. Dad spent decades building these relationships in our territory and across the industry, and when I joined him he introduced me to everyone and helped transition those relationships to ensure the business continued without a hitch.

As with most of life, it is all about who you know. There are two definite sides to the manufacturer’s rep coin. First, we need to know the heat treaters in the area. Second, we need to know the best equipment suppliers in the industry. Then we can help both by introducing them to each other. Dad spent decades building these relationships in our territory and across the industry, and when I joined him he introduced me to everyone and helped transition those relationships to ensure the business continued without a hitch.

What companies do you rep for and what products do they have to offer? Feel free to give your “principals” a free plug.

We have developed strong relationships with suppliers who are the best at what they do. In reverse alphabetic order: For high performance, industrial, air and atmosphere, batch and continuous furnaces, we rep the engineering-heavy Williams Industrial Service. When you need control upgrades, analyzers, flow meters or data loggers, turn to the industry-leading Super Systems, Inc. If you need vacuum, then SECO/VACUUM is your choice, providing high pressure gas and oil quench furnaces with all the options. The industry-standard water-cooling system is found at Dry Coolers, Inc. For freezing and tempering in the same unit, see DMP CryoSystems. For cost-competitive alloy baskets, Cooley Wire Products provides standard or custom solutions.

I would like to ask for your opinion on reps in the heat treatment industry. For many years now suppliers to the heat treat industry (at least in North America) have relied upon independent sales reps to handle their sales efforts. It has been suggested by some that with advancements in information technologies and the isolations brought about by COVID that sales reps are in danger of becoming redundant-what is your opinion? To phrase it another way what does a sales rep bring to the table? Will “road warriors” continue to have a place in the industry?

Reps aren’t going away. Workers are hard to find these days, and reps are a knowledgeable sales force with territory-specific contacts. Web meetings are a great tool, but they aren’t the same as a firm handshake and laughter over a shared meal. Plus, reps pay their own benefits and expenses, and you only pay them when there is a sale.

Earlier I mentioned that I have seen GVT evolve over the years, what I am speaking about of course is that GVT has become a significant player in supplying molybdenum to the heat treatment sector. Please tell us how this came about.

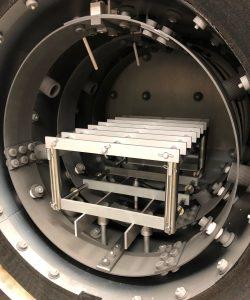

It was organic, which is a fantastic way to grow. My father has experience working for one of the major molybdenum suppliers. When he saw the need for molybdenum in vacuum furnace hot zones, he developed the contacts necessary to serve his customers at a competitive price. As the orders grew over time, it quickly became apparent that one of the major needs was quick delivery. When a vacuum furnace is down, every day can represent a large amount of lost income, especially to major captive heat treaters. Over time we developed single layer grids for vacuum furnaces, then multi-level fixtures for increasing throughput.

It was organic, which is a fantastic way to grow. My father has experience working for one of the major molybdenum suppliers. When he saw the need for molybdenum in vacuum furnace hot zones, he developed the contacts necessary to serve his customers at a competitive price. As the orders grew over time, it quickly became apparent that one of the major needs was quick delivery. When a vacuum furnace is down, every day can represent a large amount of lost income, especially to major captive heat treaters. Over time we developed single layer grids for vacuum furnaces, then multi-level fixtures for increasing throughput.

What form does this take now? For instance, I know that you have a substantial stock of moly in Idaho-is this the main part of your moly business?

We do have a large, active inventory of mill products and grids. Inventory is a large part of the business, but we also often provide non-inventory items and finished parts. We provide a substantial number of custom and standard fixtures as well.

You mention that your custom fixtures and grids business is growing-where do the designs come from?

We do the design and assembly at our facility in Idaho.

On a final note I understand that your father and founder of the business, Bob Grammer is not as involved these days. How is he doing and what is he occupying his time with these days? I am sure many in the industry are curious as to what he is up to.

Dad keeps busy! And that has not changed as he has handed the business over to me. While he is still involved in the business, he has directed much of his energy to other areas, like starting troops for Trail Life USA (a Christian leadership and outdoor adventure program for boys) throughout the Pacific Northwest. He wears several hats in the organization and loves training the next generation of men. His “leisure” time is spent in Alaska dredging for gold on his claim, teaching shooting sports, or travelling with Mom to visit his 10 (and counting) grandkids.

Did you like this article? Click here to subscribe to The Monty.

View our recent magazines and podcasts by clicking the following link. https://themonty.com/magazine/