10 Largest Single Location Captive Heat Treats-North America

For the past several weeks “The Monty Heat Treat News” (with the help of a number of our readers) has been researching the largest single location captive heat treats in North America for our list of the 10 largest. And how did we decide who should be on the list? The basic criteria includes these points;

For the past several weeks “The Monty Heat Treat News” (with the help of a number of our readers) has been researching the largest single location captive heat treats in North America for our list of the 10 largest. And how did we decide who should be on the list? The basic criteria includes these points;

- This is based upon the total number of furnaces (or cells in the case of vacuum carburizing applications) at each location as opposed to total throughput in terms of pounds.

- The main criteria is that each be a single location or campus. As an example Schaeffler Bearing ranks amongst the largest overall in terms of the number of furnaces in North America, however they are spread over quite a few different locations such as Stratford, Ontario, Canada, Joplin, MO, USA, Cheraw, SC, USA and Irapuato, Mexico to name a few. Spoiler alert-they are not be on our list for that reason.

- We want to emphasize that our list only includes captive (in house) heat treats. We received several suggestions about ALD in Port Huron, Michigan, USA who has a total of 37 vacuum carburizing cells under one roof, however this is a commercial heat treater rather than a captive heat treat and they are not included on this list.

- It is really no surprise that the vast bulk of companies on this list are automotive suppliers and in particular suppliers involved in drivetrain components-no other industries rival the sheer volumes that the auto industry handles each and every day.

- We looked closely at the aerospace industry, in particular at some of the Pratt & Whitney plants in the US Northeast and the southern states, however while a number have very substantial heat treat departments typically featuring vacuum furnaces none came close to the auto parts suppliers.

- “The Monty Heat Treat News” also looked at the oil and gas industry, however again while some suppliers such as Haliburton maintain large in house heat treats none compare in size to the firms on our list.

- It’s interesting to see how much the industry has changed over the past 20 years-an example being pusher furnaces. In 2000 we can guarantee that the largest captive heat treaters would have been very heavily weighted towards auto parts suppliers with pusher furnaces-this is no longer the case. Since then pusher furnaces have largely been pushed aside in favor of vacuum carburizing systems and batch IQ units.

- Disclaimer time. Not for a second do we claim that this list should be considered 100% accurate, however we will say with certainty that every single manufacturer on this list ranks amongst the largest in house heat treaters in North America.

Number 10 Caterpillar, East Peoria, Illinois

In years gone by we have rated Caterpillar, the world’s large construction-equipment manufacturer as one of the largest captive heat treaters in North America based on their various facilities throughout the USA many of whom have in house heat treating. Our criteria this year is slightly different in that we are looking at single location captive heat treatment facilities. However having said that we would rank the Caterpillar facility in East Peoria, Illinois as the 10 largest captive heat treat facility in North America.

Number 9 Amsted Rail – BRENCO Bearings, Petersburg, Virginia

A newcomer to our list of the 10 largest single location captive heat treaters is a bearing company, BRENCO Bearings a division of Amstead Rail, located in Petersburg, Virginia. Amsted Rail’s Brenco® Bearings was founded in 1949 to manufacture bronze journal bearings for railroad freight cars. In 1959, Brenco received conditional AAR approval for the product it is known for today throughout the worldwide railroad industry,the tapered roller bearing-in short the company makes bearings for the railroad industry. The company has locations around the world, at least two of which have in house heat treatment departments. While the heat treatment department in Petersburg is not as large as it once one it still includes multiple pit carburizing furnaces and rotary hearth units.

Number 8 Dana Corp., Queretaro, Mexico

Number 8 on our list is yet another large auto parts maker, Dana Corporation, Queretaro, Mexico. While Dana has numerous facilities around the globe that include heat treating the largest is an enormous complex in the Mexican city of Queretaro with several large, separate in house heat treating departments. There are 3 separate facilities here, Dana Forja which has a heat treating department doing annealing in continuous furnaces, Dana Cardanes which has 7 batch IQ furnaces, roughly 40 induction lines and 11 tempers and Dana, ENCO which has 2 AFC-Holcroft UBQ furnaces along with 4 pusher furnaces (as of 2020).

Number 7 Stellantis, Kokomo, Indiana

In 1956 Chrysler invested in a transmission facility in Kokomo, Indiana, a facility which now covers 3.1 million square feet (please note that there are several facilities in Kokomo, our interest is in the transmission facility). For many years now this plant which originally was called Chrysler, and subsequently FCA Kokomo before being renamed Stellantis had what was probably the largest captive heat treat in North America. At one time it included 7-Three row Holcroft Pusher Furnaces, 6-Lindberg 36 X 72 X 36 Batch IQ furnaces, 6-AFC 36 X 72 X 36 batch Austemper Furnaces, 3-Holcroft single row pushers, 2-Surface rotary furnaces, 2-Seco Rotary Furnaces, 4-ECM vacuum nitriding furnaces, 30-tempering furnaces and several ECM vacuum carburizing systems. While the heat treat department is smaller than it once was it is still one of the larger in house heat treat departments in North America.

Number 6 American Axle & Manufacturing Holdings (AAM), Silao, Mexico

In 2012 auto parts supplier American Axle & Manufacturting (AAM) formally opened a new location in the city of Silao, Guanajuato, Mexico. The Silao facility was AAM’s second manufacturing facility in Mexico, joining the Guanajuato Manufacturing Complex. The opening of these facilities marked a real change in the firms philosophy as previous to this most manufacturing was in the USA including a large facility in Buffalo, New York which featured 5 single row pusher lines. Each AAM facility (including Poland) has a varied mix of heat treating equipment which includes pusher furnaces, batch IQ’s and Induction to name a few. Each of the AAM heat treating departments is very impressive, mainly because they are relatively new and obviously no expense was spared. AAAM globally can be considered one of the larger captive heat treaters in existence.

(Photo source: American Axle and Manufacturing)

Number 5 ZF Transmission, Grey Court, South Carolina

ZF is a German company which ranks amongst the largest suppliers of automotive transmission components in the world. The location in Grey Court, SC opened in 2012 and became a hub for ZF’s work in large-scale transmission production, including eight- and nine-speed automatic transmissions. Almost exactly one year ago the company issued this press release about an expansion of the facility (an expansion which did not include more heat treating by the way), “Germany’s ZF Friedrichshafen said it will invest $200 million to build another production line at its commercial vehicle transmission plant in Gray Court, S.C. The new line is expected to begin production in 2023. More than 500 jobs will be created, the company said. The supplier on Thursday said it plans to expand production of the PowerLine, an eight-speed automatic transmission for medium-duty commercial trucks, heavy pickups and buses.”

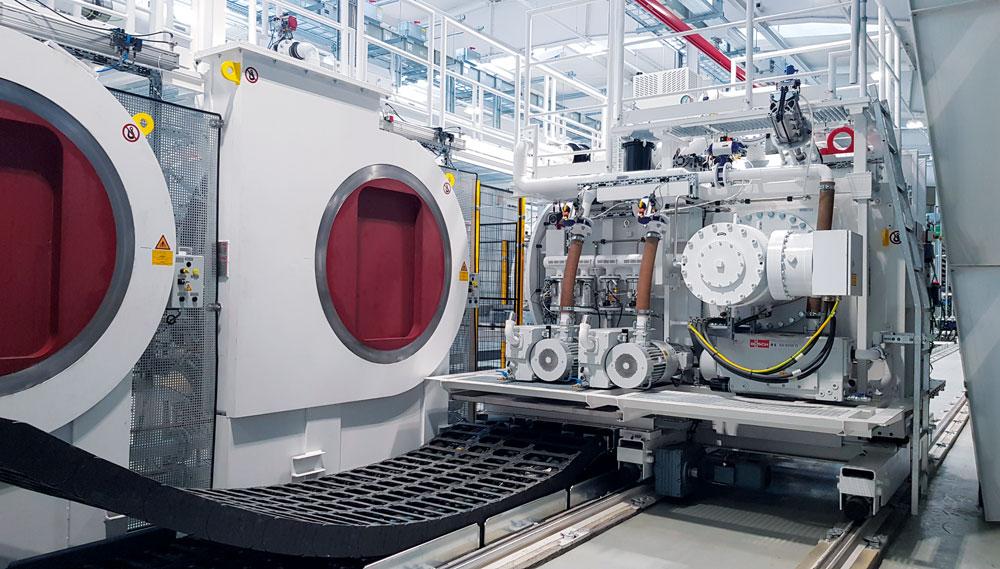

ZF is another company which made the decision to go with vacuum carburizing and the end result is that this facility has two ALD “Modultherm” systems in place with a total of 16 carburizing cells and 2 Pusher lines for annealing supplied by Ipsen.

Number 4 Linamar, Guelph, Ontario, Canada

In our fourth position we find a Canadian company, auto parts supplier Linamar. Linamar is a global company with many locations around the world doing heat treating however their largest heat treat department is in Guelph, Ontario. Roughly 15 years ago the firm made the decision to bring heat treating in house while at the same time deciding that going forward they would concentrate on batch processing as opposed to continuous. In 2022 we see that this plant now has twenty five 36” X 48” X 36” batch IQ furnaces in place combined with several vacuum nitriders and a rotary hearth furnace. Current plans include future additions to the heat treating department.

Number 3 GKN Driveline, Newton, North Carolina

In our number three position we find another automotive parts supplier, GKN in Newton, NC. While not one of the first to invest in vacuum carburizing systems they certainly jumped on the bandwagon after vacuum carburizing proved it’s value. With approximately 30 cells in operation this location clearly deserves to be on our list.

Number 2 John Deere Waterloo, Iowa

As one of the world’s largest manufacturers of agricultural machinery, heavy equipment, forestry machinery, diesel engines, drivetrains used in heavy equipment, and lawn care equipment we are sure the company needs no introduction. Their location in Waterloo, Iowa would appear to be the second largest captive heat treat in all of North America with a total of 31 furnaces (we will qualify this statement slightly by saying that 10 of these furnaces are dual chamber which we are counting as two furnaces each). The equipment comes from a variety of furnace suppliers including Surface Combustion as can be seen in this photo.

Number 1 Ford Motor Company Sharonville Transmission Facility

We are quite comfortable in suggesting that the Ford Sharonville, Ohio Transmission facility is the single largest captive heat treat facility in North America. Ford was one of the first automotive companies to embrace vacuum carburising and the end result is that this plant now have over 40 carburizing cells in operation. It is worth noting that this facility has almost 2.5 million cubic feet under roof with almost 2,000 employees; “The Ford Motor Company Sharonville Transmission plant is a transmission manufacturing facility located in Sharonville, Ohio, United States. Established in 1958, Sharonville has long been the backup site for overflowing work at the Ford Motor Company Livonia Transmission plant. It is also where the Ford Crown Victoria’s transmission was once assembled for over three decades. With the Crown Victoria now discontinued, the Sharonville transmission plant currently overseas production of the 64140 6-speed automatic transmission – also known as the Torqshift – destined for the Ford Super Duty line of heavy duty trucks. Sharonville is where the Ford/GM 10R80 10-speed transmission is assembled. The facility also manufacturers individual gears for the 6R80, 6R140, 6F35, 6F50/55, 8F57 transmissions. These gears are then shipped to other Ford manufacturing plants like the Ford Motor Company Van Dyke Transmission plant and the Ford Motor Company Livonia Transmission plant.”