Plasma Nitriding Gas Compressor Cylinders, Stamping Dies & Other Cast Iron Applications by Dr. Edward Rolinski of Advanced Heat Treat Corp.

Ion (plasma) nitriding is an environmentally-friendly and safe technology allowing the treatment of ferrous alloys in a very controllable way [1-6]. The active nitrogen species are formed directly at the surface needing hardening and not in the entire vacuum chamber. Therefore, the process uses a very limited amount of processing gases, such as nitrogen and hydrogen, doped occasionally with small amounts of hydrocarbons, if nitrocarburizing is needed. As compared to gas nitriding, this method uses less gas [1]. This is the result of constant ionization and reionization of the processing gases by plasma; while in gas nitriding, the decomposed/cracked ammonia is lost already for the nitriding reaction and must be replaced with fresh gas.

AHT’s Large Nitriding Units Are Perfect for Stamping Dies & Gas Compressor Cylinders

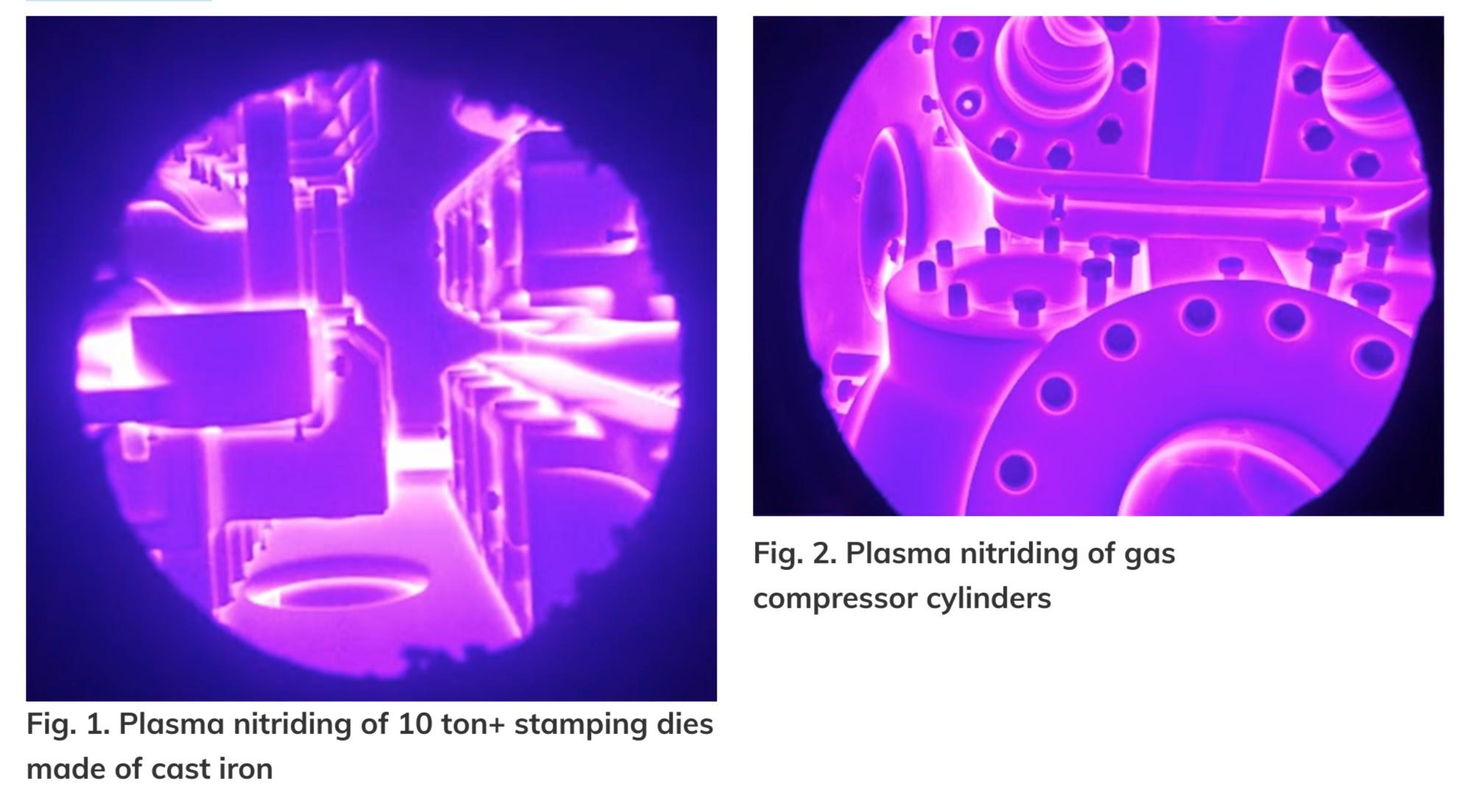

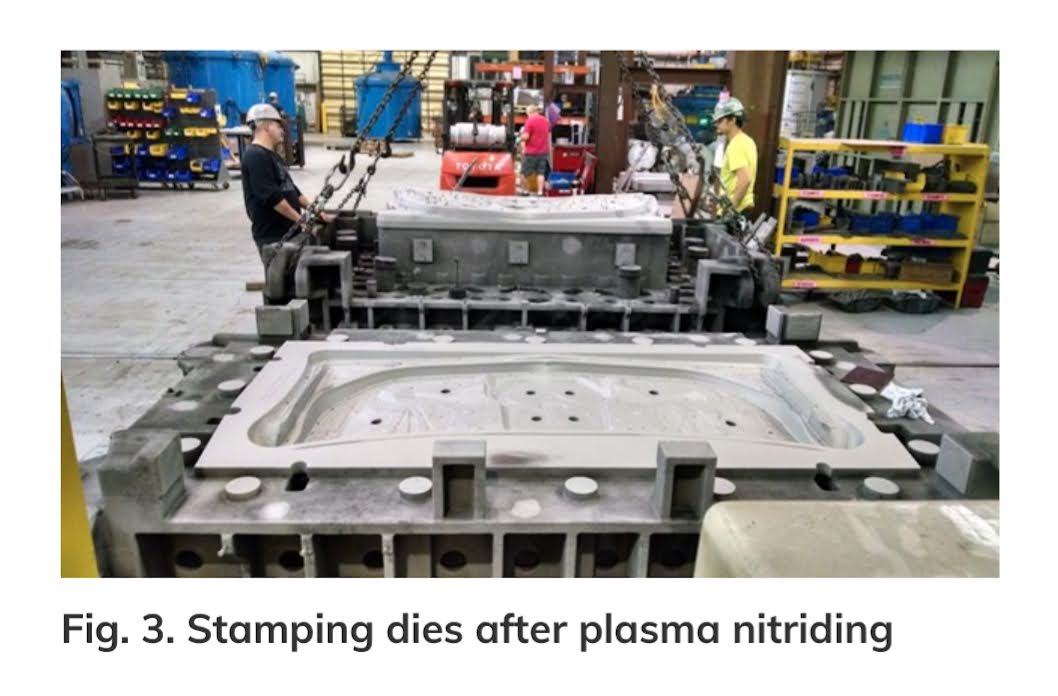

Advanced Heat Treat Corp.’s large plasma nitriding equipment allows for the processing of many large parts at the same time. Figures 1-3 show loads of stamping dies and gas compressor cylinders during and after plasma processing.

Stamping dies are the typical cast iron parts treated by plasma nitriding. The main reason for recommending plasma is a good surface roughness after processing especially when the parts are made of the gray cast irons [2-4].

Other cast iron parts quite often treated by plasma are the parts of significant sizes such as gas compressor cylinders. It should be noted here that plasma nitriding allows for easy mechanical masking of the selected surfaces, which should stay soft, such as threaded holes masked off with the bolts as seen in Fig. 2.

Benefits of Plasma Nitriding and Nitrocarburizing of Cast Irons Parts

Plasma nitriding/nitrocarburizing of cast materials, such as gray cast iron, has an advantage over gas nitriding since the active nitrogen species formed from nitrogen and hydrogen during this process do not penetrate deeply into the surface’s open porosities, grooves or other surface imperfections characteristic of gray cast iron. In gas nitriding, ammonia does penetrate those spaces and it also goes into the delineations between graphite particles and the matrix forming locally a much deeper compound layer, resulting in increased volume of the material at the surface. Therefore, roughness of this material is significantly increased after gas nitriding but after plasma nitriding it did not change much. This can be seen in Fig. 4-7 shown below.

When gas nitriding of the gray cast irons would be used, its different nitriding mechanism would result in a deep penetration of the material by the active nitrogen species such NH radicals and this can cause a significant change of the surface roughness [2, 3].

As can be seen in Fig. 4 – 7, plasma nitriding compared to gas nitriding has no nitriding mechanism-limited application characteristics in processing of any cast or porous materials. On the other hand, gas nitriding, because of its ability to penetrate deeply into those materials, cannot be used easily in such applications [2-4].

Did you like this article? Click here to subscribe to The Monty.

View our recent magazines and podcasts by clicking the following link. https://themonty.com/magazine/