Philip Reese, “Reese Hardening” Talks Heat Treating of Large Parts

Today we are very pleased to be speaking with Mr. Philip Reese, Co-Owner of commercial heat treater “HÄRTEREI REESE” of Germany. Philip right off the bat I have to say that my German is non-existent, am I correct in saying that “Reese” is pronounced “Razor”?

That is almost correct, the last “E” is pronounced. However, while I was studying in the US, I always told people “Reese” as in “Reese Witherspoon”. That way, my name was never misspelled and don’t worry – I won’t be offended if the pronunciation is not exact.”

Philip you are becoming a pretty famous guy in the heat treatment industry-just a few weeks back I watched you on the “Heat Treat Podcast”-your comments certainly attracted a lot of attention. Despite that on the off chance that anybody missed that podcast I am going to ask you to give our readers some background about yourself personally and also your company-locations, size and capabilities.

“Our first location was founded in 1948 by my grandfather in Bochum, Germany. My father and my two uncles realized that just one location was too small for three brothers when each one of them wanted to form a business with their own different ideas.

Ulrich took a chance and opened two locations in East Germany shortly after the reunification – Chemnitz and Weimar. My father started with one furnace in Southern Germany in 1989. Each location has a very different history and developed in different markets and niches, however they always supported each other when times were tough.

I personally started working for REESE in 2018, with my brother Julian starting in 2022. Originally, I didn’t want to work in heat treatment as I have a degree in Aerospace Engineering and am still excited about everything that flies. Today, I am grateful for the opportunity to work in heat treatment, the large variety of different products we treat and the many exciting projects we work on with our customers is challenging but very interesting.”

I am in awe at the size of parts your company can handle. Over the years I have had the opportunity to see your facilities several times and each time I am astounded at the size of your parts. Can you please share with us the maximum parts size you can heat treat?

I am in awe at the size of parts your company can handle. Over the years I have had the opportunity to see your facilities several times and each time I am astounded at the size of your parts. Can you please share with us the maximum parts size you can heat treat?

“For quench and temper as well as case hardening, the maximum dimensions are 195” in diameter and 215” in length. We find it very important that for all parts that come close to these dimensions, we have a thorough assessment about how to load them in the furnace. This might require supporting structures and/or counterweights on the load to deliver the results required-this is crucial to delivering top quality.”

As far as you know do you have any competition for parts of this size? The extension to this question would be do you have many customers outside of Europe because of your unique capabilities? Specifically, I am thinking of the closure of commercial heat treater Metlab in the USA a couple of years ago-a company which offered the largest pit carburizing furnaces commercially available in the country-did this lead to new opportunities for you?

Of course there is competition. There are multiple heat treaters around that will treat similar dimensions. However, some processes we offer at REESE are unique and even patented. For many types of welded large gears for example we offer a vertical treatment that leads to far less distortion.

Whenever a heat treater is confronted with a new part, he/she needs to wonder:

- What stages of transformation happen inside the material during the process?

- How strong will the design be during each stage to support its own weight?

- What areas will suffer most during heat treatment?

We need to answer these questions and others before we process any parts. Having a vertical option allows us to be far more flexible and offer the best solution possible. The feedback we get from our customers is very positive. Once they adapt their planning to our results, they usually save many hours of expensive grinding afterwards.

What else are important things to consider when working with such large and individual parts?

“We put lots of efforts in the design of our loading equipment. For complicated parts, we have patented solutions to adjust our castings to the payload. I have not seen any other heat treater making such efforts.

Another important consideration is the behaviour of our furnaces during the heat treatment cycle. For smaller parts, one can assume that the result will be uniform on all parts of the surface – only influenced by the geometry. In a large furnace with large parts, it is much more important to control the process parameters everywhere. This is a bigger challenge for the design of process controls. A big furnace grows multiple inches during a typical cycle, this means advantages and disadvantages.”

Absolutely no pun intended but lets switch gears and talk about a brand-new facility you are constructing in Bochum. I understand that this will be dedicated to Induction hardening but that is the sum total of what I know-what else can you tell us?

Absolutely no pun intended but lets switch gears and talk about a brand-new facility you are constructing in Bochum. I understand that this will be dedicated to Induction hardening but that is the sum total of what I know-what else can you tell us?

“We started construction of our new facility a couple of weeks ago and we plan on opening in the Summer/Fall of 2026. We observed that there are a lot of changing dynamics in the market and induction hardening is becoming more popular amongst engineers. For many parts, we have the opportunity to save on energy costs by using induction.

Another point is, that induction hardening offers many possibilities to collect and use data more easily than in closed furnaces. With our older equipment, we couldn’t offer the latest features and had less chances to participate in research and developments. I’m a tech guy and if there is something new making life easier for us and our customers – I want to offer that! The new facility with new equipment and machines has been designed to meet all the requirements we estimate to appear in the next decade – I hope longer.”

What prompted this large investment, especially in light of the fact that business conditions in Europe generally aren’t optimum these days.

“We analyzed what challenges heat treatment is facing in general and in particular what challenges the processes we offer are facing. From our conversations with customers and researchers we expect a more dynamic market in induction hardening and a significant amount of innovation. Our investments don’t aim for growth. We want to improve our market position and still be among the top suppliers for heat treatment services when better days come for the industrial sector in general.”

In my previous question I suggested that business conditions in Europe these days are not great-what are you seeing?

“I don’t share the perception that conditions in Europe are bad. The know how, the industry clusters we have can’t move somewhere else. Many companies that move elsewhere quickly realize later that they were far more dependant on their suppliers and circumstances at their original location than they expected.

Energy prices are a challenge for sure. Complaining that Europe’s industry is not doing great for the moment will not solve this.”

Philip can you dig out your crystal ball and make some predictions about the future of heat treating? For instance, do you see any substantial changes in heat treatment technologies in the future?

“Personally, I don’t expect the established procedures to change a lot. Heat treatment is sometimes more art and experience than engineering-changes come slowly.

But I expect the use of data and AI to play a very important role even for small heat treaters. At REESE, we have more than 3,000 active customers with thousands of products, heat treatment processes and different parts. The data we collect there will become the commodity we are going to exploit and digitalize our experience.

The principles of heat treatment will not change, but the details of our processes certainly will. In general, there is hardly a technological product that does not include steel and heat treatment in some way. Heat treaters will be needed wherever production is happening.

Philip I thank you for your time and look forward to seeing you in the near future.

Did you like this article? Click here to subscribe to The Monty.

View our recent magazines and podcasts by clicking the following link. https://themonty.com/magazine/

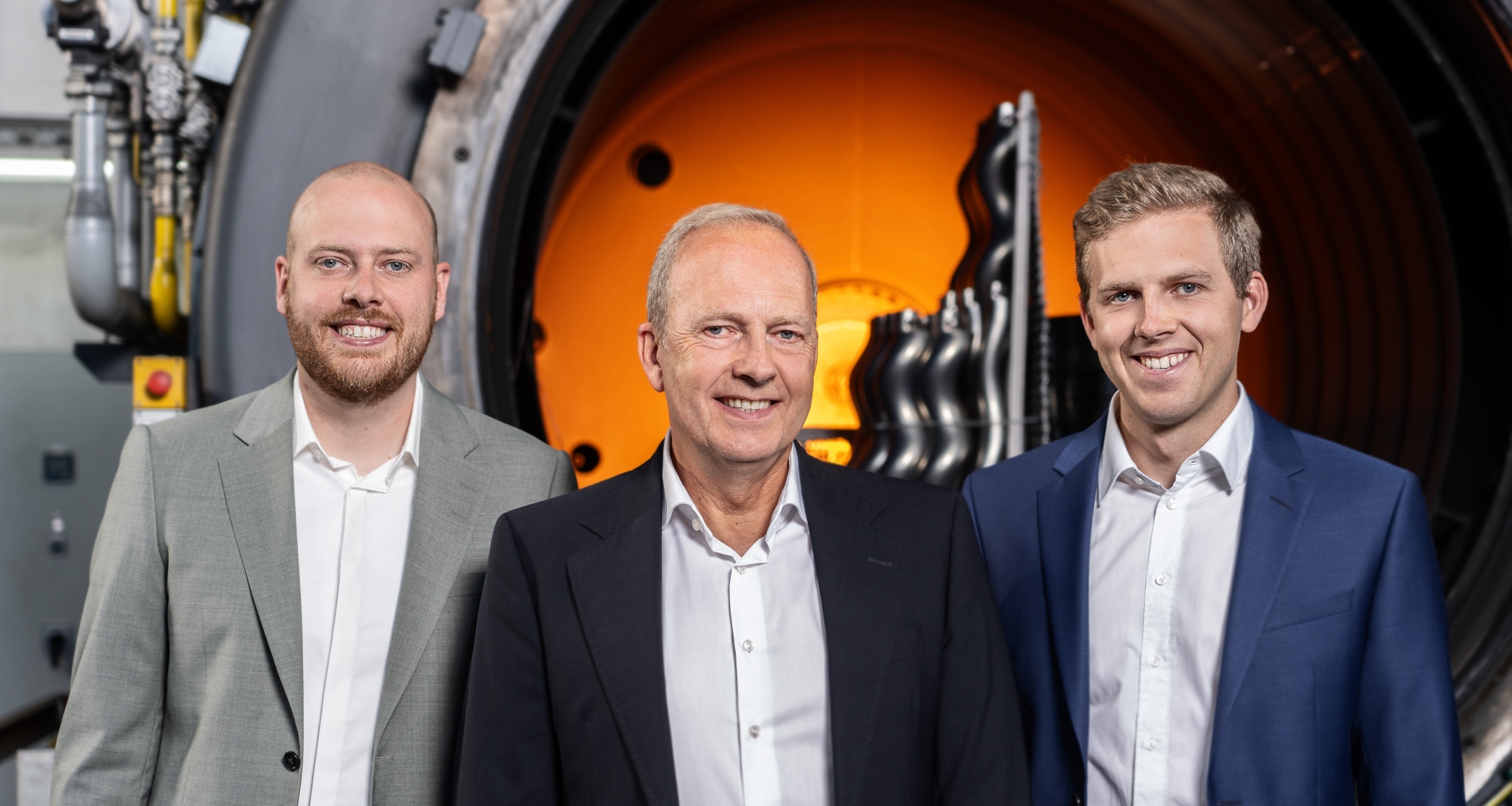

Left to Right: Philip Reese, Joachim Reese, Julian Reese