NASA’s Moon To Mars Mission

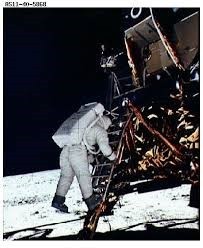

Astronauts Neil Armstrong, Buzz Aldrin and Michael Collins set out on what must have been considered at that time, the most adventurous journey ever undertaken by mankind. An epic mission for man to set foot onto another astronomical body, a journey of great courage and outstanding engineering.

Equally so, its propelled engineering design, metallurgy, physics and chemistry to beyond its known limits!! Now NASA plans an even more epic journey to travel away from Earth to a staging post on the Moon and then onwards to Mars known as the Red Planet. We can get to the moon which is a known fact. For our Industry (metallurgy and heat treatment), it is beyond an adventure as it will test our knowledge, our inventiveness, stretch our imagination, and take us on an equally epic journey of metallurgical proportions, one that we have never previously experienced. Think about that!

It will mean an extended period at the ‘staging point’ to assemble the Mars vehicle to withstand the rigours of temperatures and pressures in space never experienced by mankind, the dangers of micro-meteor strikes that would compromise the structure of the vehicle and the safety of the astronauts, and the on-board equipment functionality for the onward journey to the Red Planet.

So where does all the prior research and knowledge of the Red Planet by the numerous Rover missions help the engineers and/or metallurgists? In reality (and imho) it means that the strictest of;

- Steel-making (including titanium alloy manufacture for undercarriages, and landing skids) will demand perfection.

- The most stringent new metallic material specifications will have to be developed, adhered to and proven that the material can be manufactured to those new specifications.

- New heat treatable aluminum alloys or composite materials will need to be developed for external structural coverings of the vehicle in order to travel to the Red Planet from the Moon, as well as being used for structural members.

- Thermal strengthening specifications (heat treatment) will need to be developed as well as approval audits to process the estimated standards that will be required for the complete project.

- Metallurgical processing furnaces will need to be manufactured to the highest standards that have ever been seen in our history.

- Advanced training in metallurgical procedures and equipment that will be developed will need to be addressed and implemented.

- New major testing of specifications and the interpretation of results will need to be understood.

Major challenges will face whoever of our industry that desires to be a part of this most historical journey that mankind will ever have taken.

- Our understanding will be challenged beyond measure

- Our knowledge will be stretched beyond imagination

- Our inventive thinking will have to grow beyond resolve

In life I learned three simple things;

- There is no such thing as a bad idea until proven it’s a bad idea

- Challenge and test your ideas

- Think outside the box

The question needs to be asked of our industry of captive heat-treaters, commercial heat treaters, as well as corporations, scientists, metallurgists how and when we will develop new educational standards, new process control systems, new metallurgical processing equipment, and new leaders in our field but more importantly are we prepared to be a part of this new challenge.

Food for thought …

The Wright Brothers flew their first propeller-driven, powered aircraft on December 17, 1903, at which time my father was one year old!!

Armstrong and Aldrin were the first moonwalkers occurred on July 20, 1969, just 66 years after the Wright Brothers’ propeller-driven flight.

Using 2019 as a date of remembrance, we, the United States of America, are actively pursuing another journey from Earth to Moon to Mars just 116 years after the first propeller-driven flight. Though the journey is still being seriously planned, what an accomplishment and achievement by the country that leads the world’s aviation history. Onward and upwards for the United States of America.

David Pye, Pye Metallurgical International Consulting (PMIC), USA

(Note: NASA’S Moon to Mars Mission Part 2 will be continued on The Monty’s Heat Treatment page.)