Nitrex Changes & More Heat Treat News

Last week, Wednesday May 13 to be exact we published our 2020 list of the 30 Largest North American commercial Heat Treaters https://themonty.com/project/largest-north-american-commercial-heat-treats-august-2020/ For over 20 years we have been publishing this annual list but this year we vastly expanded the scope from the 10 largest to the 30 largest. Our research in preparation for this article covered several months and we are rather proud of our efforts-we would be pleased to hear your comments. One of the companies on this list is “Nitrex” a company which has been in the news quite a bit recently mainly because of their rebranding efforts which we mentioned last week. The press release which was issued was interesting but made no mention of some of the other accomplishments the company has made recently. For instance their manufacturing facility in Poland has been vastly expanded and the Chicago heat treating plant is seeing some major investments. In addition their GM Enterprises division in California has a fairly new Vice President/General Manager, a fellow by the name of Larry Jackson who we don’t know personally. The photo below shows the facility in Poland, on the left is Gord Montgomery on the right Michael Korwin the founder of the company.

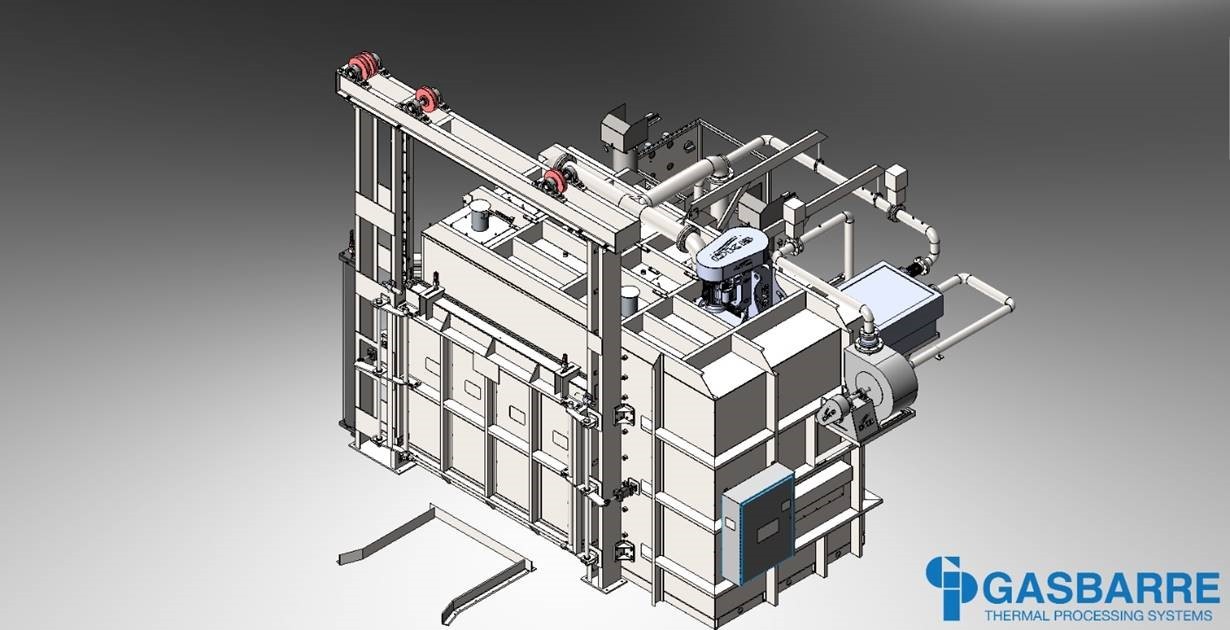

From furnace builder Gasbarre whose ad can be found on this page we have this press release; “Gasbarre Thermal Processing Systems recently shipped a custom built atmosphere tempering furnace to a manufacturer in the Aerospace market with captive heat treating capabilities. With a working load size of 84” wide, 42” deep, and 60” tall, coupled with a max load weight of 6,000 pounds, the furnace is specifically designed for our customers key manufactured components. The electrically heated furnace has an operating temperature range of 350℉ to 1600℉, and passes uniformity at +/- 10℉ per AMS2750E. The system is equipped with custom controls including Eurotherm brand temperature controlling instrumentation, and an Allen-Bradley PLC and HMI. Automatic atmosphere control is included for running under Nitrogen, Argon, and/or a Hydrogen blend. Custom designed atmosphere cooling systems are installed to reduce overall cycle time. Gasbarre was chosen as a partner for their ability to specifically design the equipment around their broad process parameters. The equipment configuration also enabled the customer to switch from pit furnace style processing, which eliminated infrastructure costs and maintenance concerns.”

From Heat Treatment Australia (HTA) we have this press release about their Los Angeles, California facility; “ HTA is pleased to announce the completed installation of a new furnace at our Los Angeles Branch, now available for precipitation hardening of PH stainless steels up to 14′. The new equipment’s maximum processing footprint is 168″ x 48″ x 48″ and is ready now to begin filling orders. HTA Los Angeles maintains AS9100 and NADCAP accreditation, and the new processes are accredited to Lockheed Martin and Boeing specifications.”

Heat Treatment Australia is also in the news in Australia where the company recently received a grant from the Defense Department. The grant will be used to expand testing capabilities for components related to the F-35 program. The photo below shows the HTA team at the Brisbane, Australia facility, this photo was taken a few years back when we visited the various HTA facilities.