Monday Morning Briefing

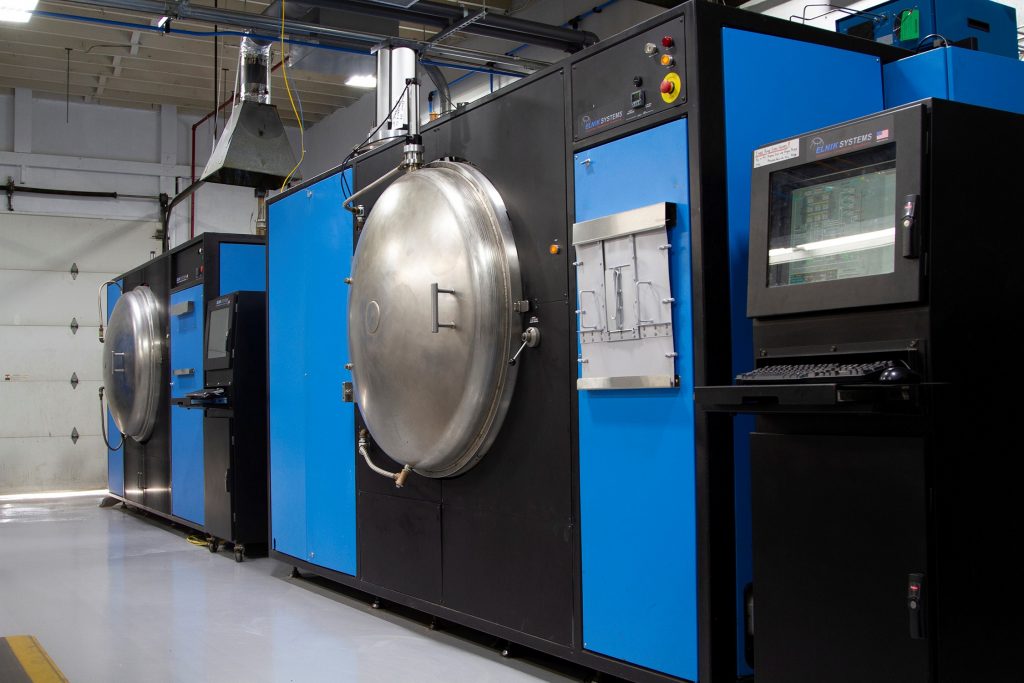

We will start off in North Carolina, USA with a story about commercial heat treater East Carolina Metal Treating expanding. Just a year ago we had this story about the company and mentioned that their division in Lynchburg, Virginia, Virginia Metal Treating would soon have a new building. Well the time is now, material has been delivered and construction is starting. We have this original story about the company along with a photo of the owner, Mr. Jamie Ramm; “May 2019. In Raleigh, NC, USA we find a good sized commercial heat treat which has been in the news quite a bit recently, mainly because the President, Mr. Jamie Ramm keeps buying new equipment which turns into industry wide press releases. To find out what all the fuss is about we at “The Monty” decided to visit since the last time we were here was roughly 10 years ago. What we found was a 45,000 square foot building with roughly 70 employees and some real nice looking equipment which includes a row of vacuum furnaces, batch IQ furnaces, Nitrex nitriding furnaces and some Induction thrown into the mix. The company was founded back in 1976 and Jamie has been here for over 30 years. We mention about the company expanding-that is only partly true. The company has a second location, Virginia Metal Treating in Lynchburg, Virginia with 10 employees and this is the location expanding. Land has been purchased and a brand new structure of 20,000 square feet is in the works.”

We will start off in North Carolina, USA with a story about commercial heat treater East Carolina Metal Treating expanding. Just a year ago we had this story about the company and mentioned that their division in Lynchburg, Virginia, Virginia Metal Treating would soon have a new building. Well the time is now, material has been delivered and construction is starting. We have this original story about the company along with a photo of the owner, Mr. Jamie Ramm; “May 2019. In Raleigh, NC, USA we find a good sized commercial heat treat which has been in the news quite a bit recently, mainly because the President, Mr. Jamie Ramm keeps buying new equipment which turns into industry wide press releases. To find out what all the fuss is about we at “The Monty” decided to visit since the last time we were here was roughly 10 years ago. What we found was a 45,000 square foot building with roughly 70 employees and some real nice looking equipment which includes a row of vacuum furnaces, batch IQ furnaces, Nitrex nitriding furnaces and some Induction thrown into the mix. The company was founded back in 1976 and Jamie has been here for over 30 years. We mention about the company expanding-that is only partly true. The company has a second location, Virginia Metal Treating in Lynchburg, Virginia with 10 employees and this is the location expanding. Land has been purchased and a brand new structure of 20,000 square feet is in the works.”

Well this isn’t good-another bad heat treating job; “Hoods that unexpectedly open have caused a recall of 2,000 model year 2020 Chevrolet Silverado 2500 and 3500 and 2020 GMC Sierra 2500 and 3500 trucks with hood latch striker problems. General Motors says the striker wires may break because they weren’t properly heat treated, allowing the hoods to open while driving. The hood striker wires can become brittle due to improper heat treatment, and the only possible warning a driver might have is the sound of striker wires rattling when they partially fracture. GM discovered the problem in October 2019, when engineers found a fractured hood latch striker wire on a company-owned 2020 GMC Sierra 2500. The following month, engineers found another fractured striker wire on another truck, causing the automaker to open an internal investigation. Hardness testing was conducted on the first striker wire and engineers confirmed the wire’s metal hardness was far higher than specifications. The hood striker assembly supplier informed GM it used an alternate supplier to heat treat two batches of striker wires in January 2019.” Recently we mentioned how in house heat treater Poclain Hydraulics in Wisconsin, USA was selling off an ECM vacuum carburizing system that the company has operated for a number of years. The system is still available-and the reason the company is looking to sell? They are contemplating a switch to Nitriding.

Last week we told the story of Metex Heat Treat in Ontario, Canada which has almost the largest capacity in North America for heat treating fasteners ordering another mesh belt furnace line. This was a 7200 pound per hour monster and it was purchased from a Canadian manufacturer by the name of Can Eng. We’re not going to dwell on the Coronavirus too much today but we do want to mention what a German industry supplier is doing to reduce the risk of transmitting the virus-different shifts. Basically the company is now operating two shifts 5:00 – 12.30 and 1:30pm – 9:00pm which reduces the number of people in the plant at any given time. Interesting idea. While we are talking about it though we ran across this company in New Jersey, USA who is offering to debind and sinter parts at no charge if they are needed in the medical industry; “Debinding and sintering experts DSH Technologies, a sister company of Elnik Systems, LLC, headquartered in Cedar Grove, New Jersey, USA, is offering its debind and sinter services at no charge to those working to produce additively manufactured metal parts in response to the coronavirus (Covid-19) crisis. DSH Technologies has the capability to water, catalytic and solvent debind parts that have a first stage binder as well as debind and sinter any metal parts built with a single stage binder, such as Binder Jetting.”

Recently Hot Isostatic Pressing has been in the news quite a bit recently because several companies have made large investments in the technology. Two that recently invested now have NADCAP approval; “Stack’s Hot Isostatic Pressing (HIP) Facility Completes Nadcap Audit; We are proud to announce we have completed our Nadcap audit for our hot isostatic pressing facility in Albany, Oregon. This diligent and meticulous process would not have been completed without the hardworking staff at our Albany site, and our partners, Quintus Technologies and Messer Group. We are expected to be officially Nadcap accredited in mid-late April. Keep checking back for more information.”

And another; “Paulo is proud to announce the addition of Hot Isostatic Pressing to the Nadcap Scope of our Cleveland Division. The Cleveland plant has held Nadcap for heat treatment, brazing, and testing for many years. The recent investment adding HIP to our portfolio of services was driven by the market need for more Nadcap approved sources for HIP. Throughout the startup phase and into early production work of non-Nadcap customer work our Quality and Operations teams knew the goal was Nadcap accreditation. In early December a three-day on-site audit was conducted which resulted in approval.”

Ford vs; Ferrari. This final item today has a very loose connection to heat treating at best but we still found it interesting. The recent Matt Damon movie, Ford vs; Ferrari is about Ford’s drive to beat rival Ferrari and win “Lemans” which they did in 1966 with a Ford GT40. Only a limited number of these cars were ever built and one is owned by a commercial heat treater in Santiago, Chile by the name of “Tratamientos Térmicos Panamericana Norte”. We have this March 2019 photo of Dale Montgomery of “The Monty” standing beside the GT40 and also a picture of the heat treat plant. The moral of the story? There is very good money in commercial heat treating when you have no competition.