Monday Morning Briefing

For our December 17, 2018 Monday Morning Briefing we are going to start off with HALEX Group, in Germany one of the 10 largest commercial heat treaters in Europe. If you recall we recently spoke about the company after visiting one of their plants, HÄNDLE Härterei GmbH., in Tubingen, Germany (photo below). When we spoke about them they had a total of 8 plants around Europe, according to this press release they now have 9 plants; “ARQIS has advised HALEX Holding GmbH on the acquisition of all shares in Forte Wärmebehandlung GmbH from Forte Heat Treatments Limited. Forte Heat Treatment GmbH specializes in the heat and surface treatment of metallic materials with state-of-the-art automated production lines. Forte’s quality standards are geared, among other areas, to the automotive supply industry. With 15 years of experience and around 70 employees, the company generates an annual turnover of more than eight million euros and has established itself stably in the heat treatment market. The HALEX GROUP was founded in 1990 and is a successful German corporate group with two business divisions. The Aldenhoven-based company is one of the leading manufacturers of aluminum extrusion tools and service providers for metal finishing by heat treatment and hardening techniques in Europe. HALEX now has around 460 employees and 12 locations in Germany, Italy, the Netherlands and Romania.”

By now everybody is well aware that P&L Heat Treating in Youngstown, Ohio, USA was recently acquired by Thermal Process Holdings. It was an interesting enough development that we at “The Monty” visited the company last week and came away with a better understanding of the company and why it was of interest to Thermal Process Holdings. The company was founded 40 years ago by Bill Pociask and since that time has grown into a 25,000 square foot facility with 15 employees and a growth rate which would be the envy of most commercial heat treaters. What would make it most interesting as an acquisition is the equipment and processes the company has to offer, namely several very advanced vacuum furnaces combined with a number of gas nitriders-both of which represent high value, high margin growing technologies. Bill entered discussions with Thermal Process Holdings roughly 11 months ago and has agreed to a one year contract with the company with the likelihood that he will continue to be involved. As a matter of fact Bill told us that he is extremely comfortable leaving the company in the hands of John Hubbard and company and is pleased that the name P&L will remain. We mentioned the equipment-what we saw were 5 quite new vacuum furnaces with quenching up to 12 bar and several pit gas nitriders again fairly new. We found it quite interesting that two of the vacuum furnaces and one of the nitriders (all installed within the past two years) were built by Remix, a Polish furnace builder who we have never run across before in North America. Future plans include a 9600 square foot addition, another vacuum furnace and another nitrider, all of which will be purchased early in the new year. Yes we can see why P&L would be of interest to anybody looking for acquisitions within the industry.

Commercial heat treater Modern Heat Treat in Richland Hills, Texas will shortly be receiving two additional brand new Batch IQ furnaces from furnace builder AFC-Holcroft in Wixom, Michigan which will be #10 and 11 if memory serves us correctly. We are looking forward to a press release with more details in the very near future. Commercial heat treater and induction supplier Indianapolis-based Contour Hardening Inc., has been in the news a great deal recently and has been mentioned several times on “The Monty” with more news to come. However the company has been attracting attention from a number of different sources recently including the Indianapolis Business Journal https://www.ibj.com/articles/71693-indianapolis-based-contour-hardening-has-new-leader-huge-growth-plans It is quite an interesting article and even includes several quotes from Gord Montgomery of “The Monty” which shows it must have been a slow news day. The photo below shows the great man himself, Mr. Ben Crawford, CEO of the company and Gord Montgomery in a photo taken just last week.

Furnace builder/rebuilder McLaughlin Services in Avilla, Indiana, USA is doing well these days as you can see in these photos taken very recently. In the first photo we see Jeff and Ryan McLaughin in front of a partly completed carbottom furnace. The unit is designed for 2100F and has a very unique design in that it incorporates twin cars-it is destined for a captive heat treater in the US.

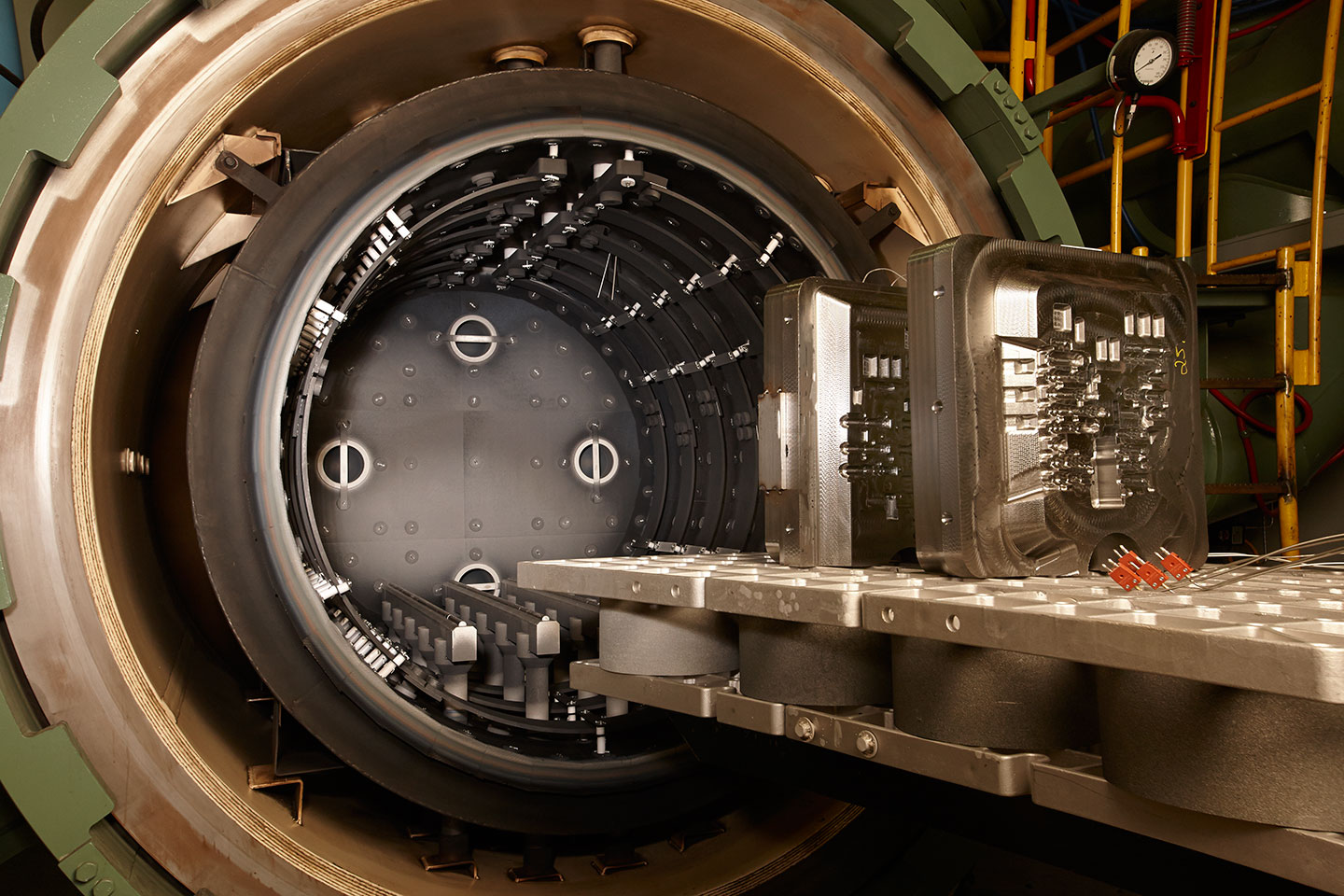

Paulo, the second largest commercial heat treater in North America just issued this press release about heat treatment of GM High Pressure Dies; “Paulo St. Louis Division gains approval for heat treatment of GM High Pressure Die Casting tooling December 13, 2018 Paulo is proud to announce the recent addition of the St. Louis Division to the approved heat treat sources list for General Motors High Pressure Die Casting Die Insert Material. The St. Louis Division joins Paulo’s Nashville plant on the approval list, which includes only seven approved locations in the US. The document, referred to as AWQ49657, covers approved material providers, heat treaters, and testing labs. Paulo is the only US source with two facilities on the list. The approval list references AWQ49658 which includes the heat treatment specifications for Hot Work Tool Steels for GM High Pressure Die Casting applications. The materials covered in the specification include H-13, 2367, and others. The approval process requires running test cycles and sharing minute by minute furnace information with GM Engineers who validate that the cycle conforms to the specification. Precise furnace controls and well maintained equipment are essential to meeting the specification.”