Monday Morning Briefing

Furnace builder AFC-Holcroft of Wixom, Michigan, USA (part of Aichelin Group) just last week held an open house as we can see in this photo. We see what appears to be a total of 4 large batch IQ furnaces in various stages of construction-no idea who they are going to.

Thermal Modification Technologies. Out in Tualatin OR, USA we find commercial heat treater Thermal Modification Technologies (which used to be called Beaver Heat Treat by the way, a name which rolls off of the tongue a lot easier than Thermal Modification Technologies but that is just our opinion). The company is quite justifiably proud of this beast which they installed not that long ago. It is a very large carbottom furnace with working dimensions of 12’ wide x 10’ tall x 45’ long.

We see that commercial heat treater Hauck, one of the largest in Europe is expanding their Dzierżoniów, Poland facility. We visited this location a few years back and at that time what we saw was a brand new plant with brand new batch IQ (sealed quench) furnaces. The man most responsible for this is the GM Mr. Bart Olegnik who can be seen in the centre of the one photo below.

Down Mexico way as they say we see that commercial heat treater Procesos Termicos HTMX has joined a small, select group of heat treaters in the country who are NADCAP accredited. The company offers batch IQ processing amongst other processes and operates under the direction of Mr. Humberto Ramos Fernández, Director General. While a fairly new company they would appear to have come a long way in a short period of time.

According to this press release SECO/WARWICK received an order for a vacuum carburizing system from an aerospace manufacturer in the US-no idea who this might be; “SECO/VACUUM Technologies (SVT), a SECO/WARWICK Group division, with its headquarters in Meadville, PA is privileged to be working with a prominent aerospace equipment manufacturer to bring their low pressure carburizing and hardening work in-house. SVT will be supplying its signature CaseMaster Evolution® (CMe) dual-chamber vacuum oil quench furnace to improve their lead times and quality objectives.“We developed the CaseMaster Evolution® to help customers in aerospace and other critical industries solve some of the more challenging issues with traditional integral quench furnaces, as well as to produce clean parts typical of vacuum furnaces, said Maciej Korecki, VP, Vacuum Heat Treatment Furnaces, SECO/WARWICK. “So, the CMe is a hybrid combining the best of both worlds, resulting in clean parts from a non-toxic work environment, providing greater repeatability of workloads, with no CO/CO2 emissions, exhaust hoods, or endothermic generators.” The Bodycote (commercial heat treating) facility in Berlin, CT, USA is pretty pleased that they recently added some more vacuum furnaces. This plant is pretty typical of most commercial heat treaters in the US Northeast in that it concentrates on Aerospace and Defense manufacturing. The Berlin plant carries Nadcap, AS9100 and ITAR to support a diverse group of Aerospace and Defense manufacturers. The plant specializes in vacuum heat treating, aluminum heat treating, raw material processing, & Electron Beam Welding.

A Giant Amongst Men? We have this rather interesting photo of Jeff McLaughlin of McLaughlin Furnace Group doing an install of some heat treating equipment in Viet Nam. This particular very large installation is for a captive heat treater making gears and the equipment is a combination of used Ipsen Sealed quench furnaces and new McLaughlin equipment.

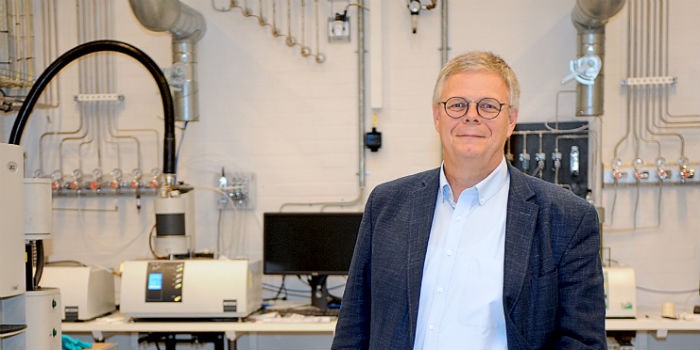

The IFHTSE (International Federation of Heat Treating & Surface Engineering) meeting is taking place in Moscow as we speak which make this news item rather appropriate. “Professor Marcel A.J. Somers has been awarded the dual honour of both receiving a rarely bestowed medal and giving a commemorative lecture at the 26th Congress of Heat Treatment and Surface Engineering in Moscow. Several years may pass between each awarding of the medal by the IFHTSE-The International Federation for Heat Treatment and Surface Engineering, a global association of heat and surface treatment organizations-to particularly prominent researchers within the field of heat and surface treatment of metals. Best known is probably his metallurgical scientific work with gas-based surface treatment of stainless steel, which his research group was one of the first to reveal the true nature of, and which laid the foundations for taking out a number of patents and forming the company Expanite.”

And to round things out we see that Terry O’Leary recently became Sales Manager Europe at Bodycote Surface Treatments after several years as the UK Sales Manager-good for him.