Monday Morning Briefing

We start off with an interview with Mr. Brian Reid of Park Thermal. The link to the interview and associated photos can be found on our home page at https://themonty.com/project/brian-reid-park-thermal/ From Brian Reid and Park Thermal we move on to our friends at Contour Hardening in Indianapolis, USA for this announcement; “Contour is proud to announce the promotion of Neil Merrell to Vice President effective immediately. Neil’s proven leadership and more than twenty years of experience with Contour has made him an invaluable member of the Contour team and has fully prepared him to accept a more strategic leadership role as Contour enters a new era in the company’s development. Neil Merrell is only the second person in Contour’s 37-year history to hold the role of Vice President. Contour co-founder, Mike Chaplin, was the first to hold this title at the company’s founding in 1986. “Neil’s a machine. He just never stops.”, Said Ben Crawford, President & CEO, Contour. Crawford added, “Every day he proves just how invaluable he is to our team here at Contour. Speaking for both myself and the Board of Directors, it’s an honor and privilege to offer Neil this long overdue recognition and promotion”. ABOUT CONTOUR HARDENING; Contour (www.contourhardening.com), based in Indianapolis, Indiana, with additional operations in Silao, Mexico, is an innovation-driven company with a strong portfolio of products and services that significantly improve heat treat processing techniques for products across multiple industries around the globe.”

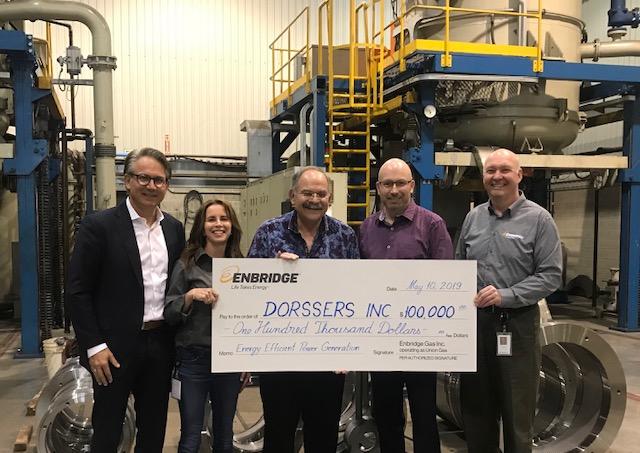

Located in the very small town of Blenheim, Canada we find Dorssers Inc., a captive heat treater and manufacturer of pellet mill dies. The company has made our news section a couple of times over the years in the form of press releases for new equipment purchases (an example from 2003 is below). The company recently made the news again when they received an award from energy company Enbridge. We mention them today because in this photo you can see the President of the company standing in front of the firms two SECO bottom load vacuum furnaces. In addition to these units the company also has a very impressive vacuum carburizing system which is relatively new; “Press Release 2003 Dorssers, Inc., has expanded their heat treat operation with the installation of two SECO/WARWICK Elevator Hearth Vacuum Furnaces with Convection Heating, rotating hearth, and 2 Bar gas cooling system for hardening pellet mill dies in their Blenheim, Ontario manufacturing facility. The furnace hot zones are 60″ (1500 mm) diameter x 60″ (1500 mm) high, with a 4,200 pound (2000 kg) hearth rating at 24000F(13200C). Dorssers, Inc. is a private corporation specializing in the production of pellet mill die and roll parts for the feed, waste and pulp industry.

A reader in the UK thought we might be interested in this item about auto parts supplier Xtrac adding vacuum heat treating capacity; “Transmission technology specialist Xtrac has appointed Piet Daenen into a newly created position of chief operating officer (COO). Daenen joins the company’s leadership team as a full member of the board to help manage its ambitious growth not just in top-level professional motorsport around the world but also in the high-performance automotive sector, where it’s supplying premium and luxury carmakers with advanced transmission systems for hybrid and electric vehicles. Mid-way through a significant investment programme Xtrac has recently completed a 27,000 sq. ft (2,510 square metres) factory extension, which takes the total size to 115,000 sq. ft (10,685 square metres) and has already added additional gear cell manufacturing facilities, 5-axis machining and vacuum heat treatment plant. The company is installing further production equipment over the next six months as well as new transmission test cells.

We will follow the previous news item up with another one from the UK; “ATL Turbine Services said the investment would increase its heat treatment capacity by 50%. Based in Piper Street, ATL is a gas turbine component repair facility, which services the marine, aviation and industrial sectors. It refurbishes parts to a fully restored condition, giving them the same integrity and durability as new components.

However, with the majority of components requiring heat treatment cycles as part of the repair process, restricted furnace capacity was a barrier to growth for the firm. Chief executive Dale Harris said: “The furnace will increase our heat treatment capacity by 50% and removes the restraint we previously experienced.” In addition to the £400,000 invested in the new furnace, the firm has spent a further £80,000 replacing its computer measuring machine, which will allow testing of component tolerance to a far higher level.

In the US commercial heat treater Advanced Heat Treat Corp., based in Waterloo, Iowa gets mentioned regularly partly because they are one of the largest independent commercials in North America. Lets mention them again today because of their most recent addition an Induction hardening system seen arriving at their Burton Avenue location in Waterloo, Iowa.

Last week we wandered through the wilds of North Carolina, USA and stumbled upon commercial heat treater Thermal Metal Treating in Aberdeen. We would consider this to be an average sized commercial shop and its claim to fame would be the cleanliness. Most of the furnaces are not new but we have never seen equipment so meticulously cleaned and maintained-it was absolutely spotless and in one of the pictures you can see why. The company has one individual whose main job would appear to be washing and painting the equipment on an ongoing basis, we were certainly impressed. If you ever have a desire to see this plant we are very sure that Mark Scott and Greg Ritter would be proud to show you their facility.