Manufacturer Brings Heat Treatment In-House Due to Long Lead Times

“The Monty Heat Treat News” has long maintained that the #1 reason manufacturers bring heat treatment in house (as opposed to sending it out to a commercial heat treater) has very little to do with costs and a lot to do with lead times and control over the process. This is yet one more example.

“BTOMEC Ferramentaria, one of Latin America’s leading injection mold producers, has invested in a single-chamber Vector vacuum furnace with high-pressure gas quenching (15 bar abs.). This is the first order from the Brazilian manufacturer placed with SECO/WARWICK, a leader in vacuum heat treatment technology, marking an important step towards full independence and integration of in-house processes.

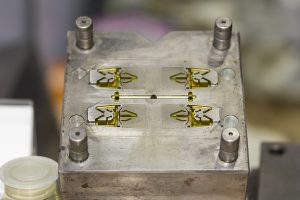

“BTOMEC Ferramentaria, one of Latin America’s leading injection mold producers, has invested in a single-chamber Vector vacuum furnace with high-pressure gas quenching (15 bar abs.). This is the first order from the Brazilian manufacturer placed with SECO/WARWICK, a leader in vacuum heat treatment technology, marking an important step towards full independence and integration of in-house processes.Established in 1985 in Joinville, Brazil, BTOMEC has long supplied multi-cavity molds for the global cosmetics, pharmaceutical, food and packaging industries. The new investment in the SECO/WARWICK vacuum furnace is a response to growing production needs. Until now, BTOMEC relied on external hardening services, but limitations in availability, long lead times, rising costs and the need for independence prompted them to create their own heat treatment department.

“This is a trend we see more and more frequently. At a certain production scale, many industrial partners begin to consider creating their own small hardening facility. Such an investment means independence from external entities and, above all, full control over the production process and its costs. SECO/WARWICK’s experience in developing technology for both small and large hardening plants, as well as extensive cooperation with entities starting their own heat treatment processes, makes us the technological partner of choice,” said Maciej Korecki, Vice President of the Vacuum Segment at SECO/WARWICK Group.”

“This is a trend we see more and more frequently. At a certain production scale, many industrial partners begin to consider creating their own small hardening facility. Such an investment means independence from external entities and, above all, full control over the production process and its costs. SECO/WARWICK’s experience in developing technology for both small and large hardening plants, as well as extensive cooperation with entities starting their own heat treatment processes, makes us the technological partner of choice,” said Maciej Korecki, Vice President of the Vacuum Segment at SECO/WARWICK Group.”