High Efficiency Burners For Galvanizing Plant

High-Efficiency and ultra-low-emission burner technology made by WS Wärmeprozesstechnik GmbH will heat thyssenkrupp’s newest hot-dip galvanizing plant in Dortmund, Germany.

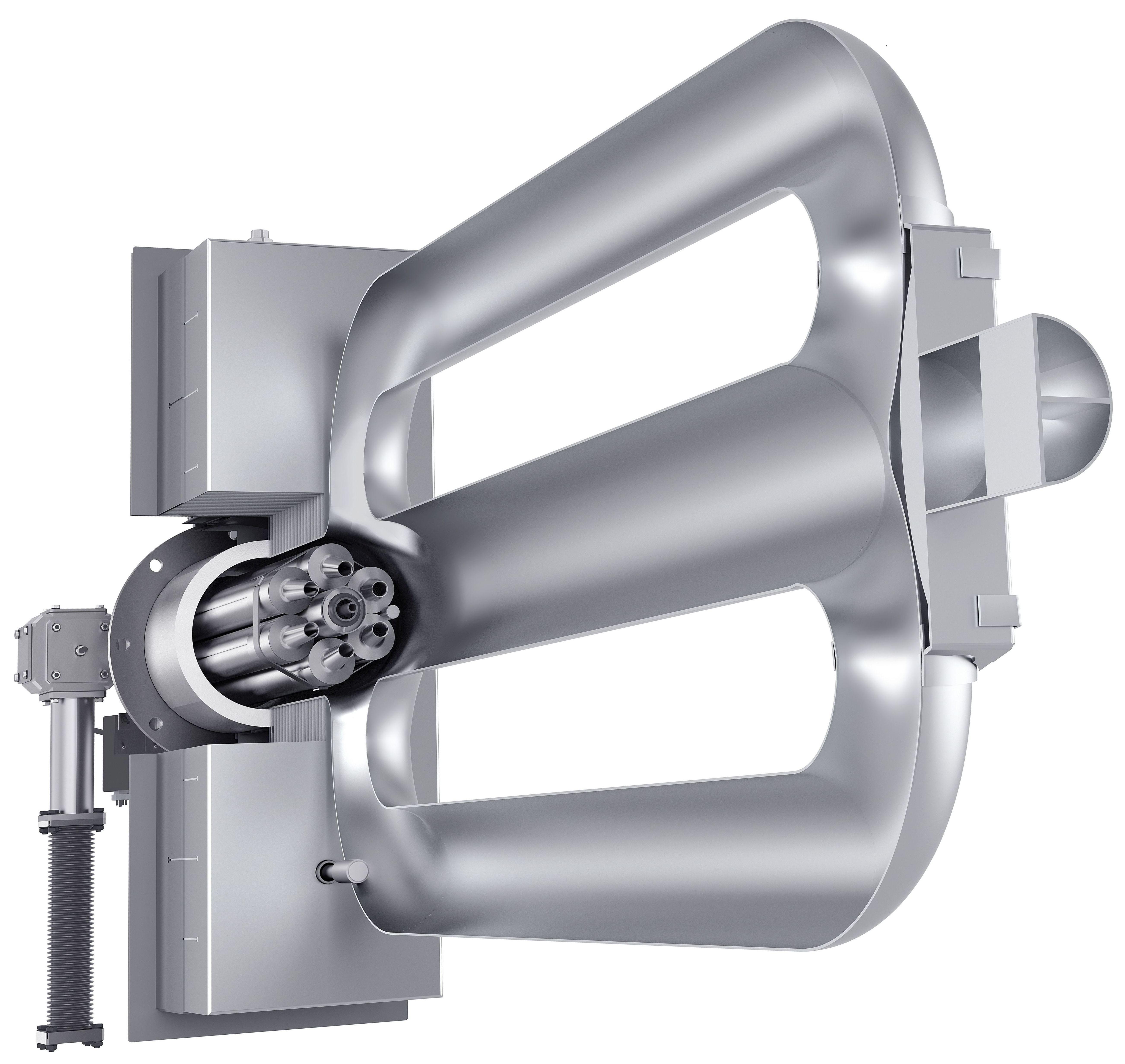

In the presence of NRW’s prime minister Hendrik Wüst, thyssenkrupp Steel recently inaugurated its newest hot-dip galvanizing line 10 (FBA 10) in Dortmund, Germany. The new line sets a global benchmark in energy efficiency and low-emission heating. By using modern regenerative burners from WS Wärmeprozesstechnik GmbH in double-P radiant tubes, the plant typically saves between 15% and 30% fuel as compared with conventionally heated furnaces. At the same time, particularly low NOx emission values are achieved, thanks to the patented FLOX® combustion process. Due to its high efficiency and the excellent temperature uniformity of the radiant tubes used, the heating system also creates a perfect basis for a later switch to green fuels such as hydrogen.

With a total of three vertical strip-processing lines, the thyssenkrupp plant in Dortmund is one of the worlds most modern locations for the annealing and surface finishing of steel strip. Together, the three lines can process up to 2,000,000 metric tons of steel per year. WS already delivered nearly 800 modern gas burners to the Dortmund location, making it one of the most advanced and environmentally friendly sites worldwide. Regarding the regenerative burners used for FBA10, Dr. Clemens Trachternach, team leader of FBA 10, says: It is the best technology available on the market, which we are installing in order to really future-proof the plant and still safely undercut the emission limits many, many years from now.

Crucial to meeting this goal is the decades of experience at WS with the multiple award-winning and patented FLOX® technology, which is already successfully in use in tens of thousands of burners worldwide. The FLOX® combustion technology allows highly efficient burners to be operated with particularly low NOx emission levels. It is our ambition at WS, to provide solutions for all continuously operated strip lines which can reliably attain NOx emissions well below 100 mg/Nm³, with simultaneously high combustion efficiency over 80% and which are, already today, suited for a future with green combustion gases says Dr.-Ing. Wünning, President of WS Wärmeprozesstechnik GmbH.

Did you like this article? Click here to subscribe to The Monty.

View our recent magazines and podcasts by clicking the following link. https://themonty.com/magazine/