Heavy Equipment Component Supplier Invests in New Heat Treat Department

It is always really “cool” to see manufacturers treat heat treating with the respect it deserves as a crucial part of the manufacturing process-let us introduce you to I.M.G. S.p.A. (INDUSTRIA MECCANICA GIRARDELLO) in Italy, a company which believes in the value of quality heat treating.

It is always really “cool” to see manufacturers treat heat treating with the respect it deserves as a crucial part of the manufacturing process-let us introduce you to I.M.G. S.p.A. (INDUSTRIA MECCANICA GIRARDELLO) in Italy, a company which believes in the value of quality heat treating.IMG supplies “under carriage” components to heavy equipment manufacturers such as “Caterpillar”-undercarriage refers to items such as chain and rollers buried in the chassis of equipment such as heavy earth moving equipment.

IMG has always believed in “in house heat treating” and when a very substantial customer ramped up production the company invested in a new “state of the art” heat treat system to meet the increased demand.

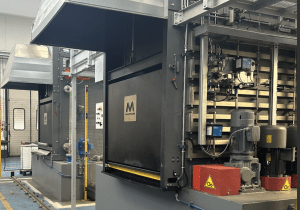

IMG has always believed in “in house heat treating” and when a very substantial customer ramped up production the company invested in a new “state of the art” heat treat system to meet the increased demand.The new heat treat system consists of 3 high heat carburizing furnaces, gas fired with working dimensions of 900mm X 1200mm X 900mm (36″ X 48″ X 36″) each with a capacity of 2,000KG (over 4,000 pounds), all using a Nitrogen/Methanol atmosphere.

Combined with the high heat furnaces are 3 tempers, a charge car and a washer all controlled by a PLC system which allows for complete automation.

Combined with the high heat furnaces are 3 tempers, a charge car and a washer all controlled by a PLC system which allows for complete automation.The entire system was provided by furnace builder “Meapforni”of Fontanafredda, Italy and was installed in 2024 with the entire system recently entering production.

As always this very successful installation was a team effort but we do have to mention that Mr. Paolo Faoro, of IMG was very instrumental in making this such a success-he is shown in the one photo along with the “Meapforni” team and Gord Montgomery of “The Monty Heat Treat News”.

As always this very successful installation was a team effort but we do have to mention that Mr. Paolo Faoro, of IMG was very instrumental in making this such a success-he is shown in the one photo along with the “Meapforni” team and Gord Montgomery of “The Monty Heat Treat News”. (This visit by “The Monty” and the resulting story occurred Thursday, March 12th)

Did you like this article? Click here to subscribe to The Monty.

View our recent magazines and podcasts by clicking the following link. https://themonty.com/magazine/

Left to Right; Francesco Pieropan, Meapforni, Vlad Kulbitski, Meapforni, Paolo Faoro, IMG, Gord Montgomery