Heat Treating Gears: Comparing Carburizing, Ion Nitriding & Gas Nitriding Authored by Dr. Edward Rolinski, Advanced Heat Treat Corp

Gear failures have been a subject of many engineering articles, also addressing thermochemical methods used for improving performance and longevity [1-11]. Gear failure can be very complex. Many gears fail from bending fatigue as a result of cyclic bending stress at the tooth-root fillet and this location is often very critical for improving longevity of these components [1]. Pitting, scuffing and wear are the next failure modes and are the result of the rolling/sliding contact fatigue (RCF) of the tooth surface and subsurface layer.

Thermochemical treatments applied to steel gears, such as carburizing and nitriding, allow for inducing a compressive stress at the surface and increased hardness which are very effective in increasing durability of the gear components.

Heat Treating to Reduce Gear Failure

Carburizing

Carburizing has been a well-known conventional surface treatment used for hardening of many gears for a long time [3]. Benefits of this process are mostly related to its ability to form a very deep case in many carburizing steels. The achievable case depth reaches 5 mm (0.2”) and this is important when a danger of the core crashing exists. This technology however, requires a high temperature for the treatment, leading to unwanted dimensional changes of the teeth during quenching and the low tempering temperature. Typically, extra significant machining is needed to make the necessary dimensional corrections after each carburizing process. Also, the low carbon steels don’t harden in the core of the gear structure leaving it with a lower tensile strength than needed for the construction of many gears.

Nitriding

Nitriding is carried out with the mid-carbon, low alloy steels at low temperature, below any phase transformation in the steel so dimensional changes are very limited. Also, the nitrided layer has much better thermal resistance than the carburized layer because of a good stability of the alloying nitrides of chromium, molybdenum, titanium and other elements present in those steels. Because of low temperature, nitriding also assures a higher strength of the treated steel in the core of the gear structure. However, since nitriding is performed at much low temperature than carburizing, diffusion of nitrogen is much slower than diffusion of carbon resulting in much thinner layer, typically ≤ 1 mm (0.040”).

The Differences between Nitriding Heat Treatments of Gears

The Plasma/Ion Nitriding Process

This process is carried out in a vacuum chamber/furnace connected to the DC power supply in an atmosphere of nitrogen mixed with hydrogen. The load/gear has a negative-cathodic polarization and the chamber wall has the anodic polarization. Ions and neutrals-energetic particles generated near the cathode bombard its surface and produce active nitrogen atoms as well as the ammonia radicals. As a result, nitrogen atoms are subjected to chemisorption at the surface and diffuse into the steels. The entire treated surface is covered with the glow discharge, Fig. 1. Masking/protection of the selected surfaces from hardening is very simple; it is done with the steel bolts, plates, etc. which cover them and protect from a contact with the glow discharge.

The nitrided layer is very hard and its thickness reaches 0.040” (1 mm), if required. Such a layer increases bending fatigue resistance of the teeth, as well as the RCF and wear resistance.

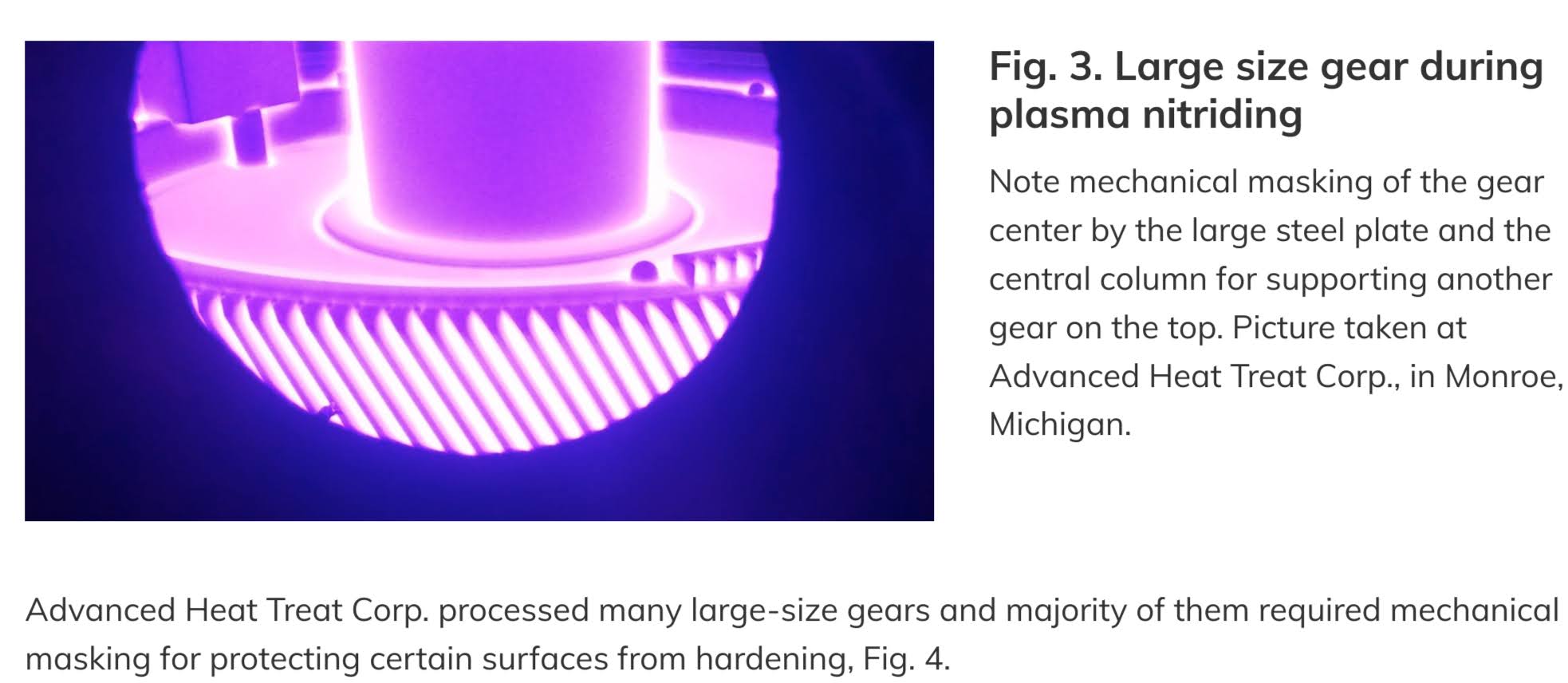

It should be noted that the core hardness of the modified Ultra-Strength 4340 type steel after nitriding stayed very high, which is a result of the low temperature of the treatment. This is important in maintaining its high yield strength. Benefits of plasma nitriding of large gears include ability of the method for forming the nitrided layer with a very minimum compound zone thickness as well as the easiness of simple, mechanical masking of the not geared sections such as its center and other surfaces, see Fig. 3.

Fig. 4. The large-sized, low-noise second reduction marine gear after plasma/ion nitriding

Picture taken at Advanced Heat Treat Corp., in Monroe, Michigan.

The Gas Nitriding Process

Gas nitriding is a simple process with a long history of successful applications. Its modern/current version, uses ammonia, ammonia mixed with the disassociated ammonia or ammonia mixed with with nitrogen. The process is controlled by setting nitriding potential and/or nitriding potential with availability of nitrogen (disassociated) and those are set with a proper software and require advanced measuring devices. The latter are important for controlling very precise cycles, which require production of the layer with a minimum compound zone.

The gas nitriding method has also been successfully used for treating various gears. Although the produced nitrided layer has the required thickness and hardness, its compound zone has a tendency to be too thick and must be mechanically removed after processing after gas method. Also, masking/protecting from nitriding in gas nitriding is more complicated than in ion nitriding. It requires a galvanic plating with a copper, which has to be removed after the processing. Benefits of gas nitriding or nitrocarburizing (FNC) can be seen when gears that do not require masking need the treatment and especially those which are very small, Fig. 5.

Did you like this article? Click here to subscribe to The Monty.

View our recent magazines and podcasts by clicking the following link. https://themonty.com/magazine/