H-13 Hot Work Tool Steels: Enhancing Wear Performance with Nitriding Authored by Dr. Edward Rolinski of Advanced Heat Treat Corp

Hot work tool steels can be hardened partially or completely by traditional heat-treating operations [1]. Their hardness stays in the range of 55 HRc even if the tempering temperature reaches 600° C (about 1100° F) which allows the use of these steels for components or tools working at elevated temperatures. This is especially important when making parts or tools for machines forming molten aluminum or other low-melting temperature metals and plastics. They are subjected to wear by friction, erosion at elevated temperatures as well as thermal fatigue. For the longevity of the machines and tools, both the core properties and the surface properties of the steel are important.

Thermochemical surface engineering, such as nitriding, further increases properties of friction, erosion and thermal fatigue [2-5]. This is possible since alloying elements in these steels, such as especially chromium, form very hard and thermally stable nitrides such as CrN.

Kinetics of Nitriding and Properties of the Nitrided Layer

Nitriding is a time-consuming process but properties of the nitrided layer overcome problems which can be encountered when only general heat treating, such as carburizing, carbonitriding and quench and temper, is used. The rate of nitriding is proportional to the square root of processing time but it is also exponentially increased by the temperature, see Fig. 1.

Nitriding Temperatures for H-13 Steel

Processing temperatures for H-13 steel can typically be set comparatively high, > 1000° F since the hardness of this steel is at its maximum if tempering temperature is close to 1100° F. This allows for an expedited nitriding process. Nevertheless, nitrided layers generally don’t exceed 0.008” thickness in an effort to control costs.

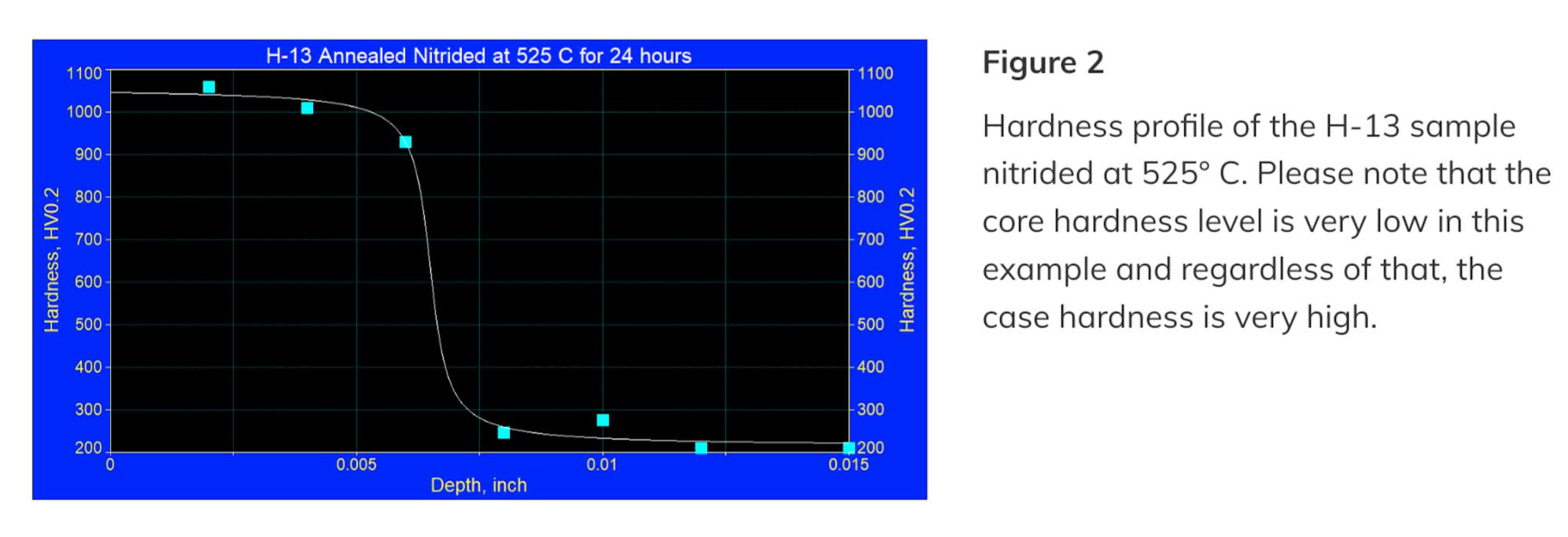

Hardness of the nitrided layer formed in H-13 steel stays very high, above 70 HRc equivalent even for soft-core components, see Fig. 2.

Nitrided H-13 Surface Hardness

Surface hardness HR15N is high and typically, depending on the case depth, is above 92.5. It should be mentioned that aluminum extrusion dies may benefit from a deep nitrided case since a majority of them fail because the stream of liquid aluminum at about 780°C washes out the surface. and This causes chemical dissolution of the steel and soldering Al to it [2-5]. The same requirement for deep case applies to some plastic tools especially those used for forming composites.

Nevertheless, thermal fatigue, often present in many of the higher temperature applications, can be better controlled when a very thin nitrided layer is formed. Attempting thick nitrided layers in those applications may have a negative effect on the performance and longevity of the tools. Also, the thickness of the compound zone (CZ or white layer) compared to the total thickness of the layer has to be limited as much as possible. The best thermal fatigue performance of the nitrided layer is when CZ of ɣ’-type is present at the surface. This guarantees that the surface stress is compressive.

Did you like this article? Click here to subscribe to The Monty.

View our recent magazines and podcasts by clicking the following link. https://themonty.com/magazine/