General Blackening of Ferrous Metals

This Article was provided by Advanced Heat Treat Corp and was written by Dr. Edward Rolinski, aka Doctor Glow.

This Article was provided by Advanced Heat Treat Corp and was written by Dr. Edward Rolinski, aka Doctor Glow.

Blackening of ferrous metals has been known for ages. In XIX century America, blackening was used extensively for guns barrels to prevent corrosion and for enhancing their general look, reducing the light reflection and increase wear resistance properties.

General blackening is quite durable and offers long-term corrosion resistance in storage or in service when mild corrosion resistance is needed [1]. The intensity of the black color is dependent on the time of immersion, the temperature of the bath, and the concentration of the bath ingredients [2]. Also, black oxide finishes require, because of their porosity, proper sealant. Depending on the sealant used, the black oxide finish can withstand 100-200 hours of neutral salt spray test ASTM B117 or several hundred hours of humidity test per ASTM D1748 [1].

General blackening is quite durable and offers long-term corrosion resistance in storage or in service when mild corrosion resistance is needed [1]. The intensity of the black color is dependent on the time of immersion, the temperature of the bath, and the concentration of the bath ingredients [2]. Also, black oxide finishes require, because of their porosity, proper sealant. Depending on the sealant used, the black oxide finish can withstand 100-200 hours of neutral salt spray test ASTM B117 or several hundred hours of humidity test per ASTM D1748 [1].

There are three types of blackening in common use: Caustic Black Oxidizing, Room Temperature Blackening and Low-temperature Black Oxide.

Advanced Heat Treat Corp. (AHT) offers Caustic Black Oxidizing carried out at 290°F, which forms a black iron magnetite. The finish does satisfy the military specifications MIL-DTL13924 and AMS2485 [2]. The most common applications of this treatment are in the mechanical engineering and firearms industry for enhancing chemical, mechanical and optical properties of the components, see Fig. 2.

Nitriding/Nitrocarburizing with Blackening

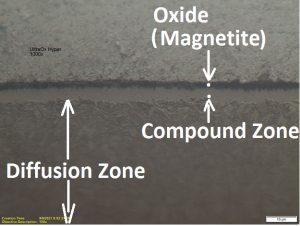

Combining nitriding/nitrocarburizing treatment with post oxidizing delivers even more superior properties to the heavy-duty mechanical components resisting abrasive wear in corrosion applications. Nitrided layer consists of compound layer and the diffusion layer. Addition of the oxide on top of it significantly improves corrosion and wear properties. Intensive research work within the last 40 years consistently proved the increased resistance of compound layers against neutral salt solutions and atmospheric corrosion can be even more enhanced by optimizing content of nitrogen and carbon in it and additional post-oxidizing [3]. This is particularly valid in the case of their resistance against pitting corrosion caused by chloride ions [3]. In addition, the aesthetic appearance of the parts is also increased. Post-oxidizing can be realized by the low temperature caustic additional process or in situ the post-ox step as a portion of the post-FNC sequence. The latter technology introduced in 80’s significantly increases corrosion resistance and also further enhances hardness and tribological properties of heavy duty components [3, 4].

Combining nitriding/nitrocarburizing treatment with post oxidizing delivers even more superior properties to the heavy-duty mechanical components resisting abrasive wear in corrosion applications. Nitrided layer consists of compound layer and the diffusion layer. Addition of the oxide on top of it significantly improves corrosion and wear properties. Intensive research work within the last 40 years consistently proved the increased resistance of compound layers against neutral salt solutions and atmospheric corrosion can be even more enhanced by optimizing content of nitrogen and carbon in it and additional post-oxidizing [3]. This is particularly valid in the case of their resistance against pitting corrosion caused by chloride ions [3]. In addition, the aesthetic appearance of the parts is also increased. Post-oxidizing can be realized by the low temperature caustic additional process or in situ the post-ox step as a portion of the post-FNC sequence. The latter technology introduced in 80’s significantly increases corrosion resistance and also further enhances hardness and tribological properties of heavy duty components [3, 4].

UltraOx Hyper Optimizes Nitrogen and Carbon Content in Compound Zone

UltraOx Hyper technology invented by Advanced Heat Treat Corp. allows for optimizing nitrogen and carbon content in the compound zone to maintain it above 8.5% by weight before the magnetite layer is formed at the surface. All those well-controlled post-nitriding oxidation properties can even be more enhanced when additional corrosion inhibiting organic sealing of the microporous surface is used as it is done by the Hyper treatment.

UltraOx Hyper technology invented by Advanced Heat Treat Corp. allows for optimizing nitrogen and carbon content in the compound zone to maintain it above 8.5% by weight before the magnetite layer is formed at the surface. All those well-controlled post-nitriding oxidation properties can even be more enhanced when additional corrosion inhibiting organic sealing of the microporous surface is used as it is done by the Hyper treatment.

Structure of the near-surface layer of the components treated with one of the above technologies is quite complex and every detail of the layer is very precisely controlled by proper processing. Examples of those layers are shown in Fig. 4. Application of UltraOx and Hyper technologies are growing in demand since they can be used in the most challenging applications where the others anti-chafing and anti-friction technologies are not sufficiently good.

Did you like this article? Click here to subscribe to The Monty.

View our recent magazines and podcasts by clicking the following link. https://themonty.com/magazine/