Furnace Builder Can Eng Invites “The Monty Heat Treat News” to Visit

“Dear Gord, I wanted to extend an offer to you and your team to visit us here at CAN-ENG so that we can share with you what’s new. Although the recent pandemic years have brought a multitude of challenges to our industry, CAN-ENG has been resilient, developed alternate strategies to overcome these challenges and as a result has prospered during these times.

CAN-ENG entered the Pandemic as the 2019 year ended with a robust mix of projects. As the pandemic ensued, CAN-ENG has successfully attracted new business, partnerships, and market segments. This growth was made possible because we remained committed to our Founders’ guiding principles. Our fundamental values include focusing on customers’ future technological needs and continuous improvement of core products.

CAN-ENG is happy to reveal with you that since the onset of the Pandemic, CAN-ENG has taken part in over Twenty (20) Large Thermal Processing Equipment contracts. The mix of recent projects include: Mesh Belt Quench and Temper Furnaces for High-Quality Fasteners, Mesh Belt Austemper Systems, Aluminum Component/Casting Heat Treatment Systems used for vehicle light weighting initiatives and developments in alternate fuel and electric vehicles, Steel Heat Treatment systems for electrical steel annealing, forged drive component Iso-thermal annealing, rail, construction, military, and aerospace component processing.

With the additional recent support resources provided by our new sister companies JTL Integrated Machine and Trenergy Inc., CAN-ENG is progressing with on-time deliveries of major projects through the end of 2022 and early 2023 that specifically include: Two (2) Mesh Belt Heat Treatment Systems, Electric Vehicle Drive Component Atmosphere Heat Treatment System, Modular T-7 Heat Treatment System with Precision Air Quenching (PAQ™) Technology and Rotary Hearth Rail Car Component Heat Processing system. These contracts will be commissioned globally by our dedicated team of furnace engineers, some of which integrating electric heating systems to meet the demands for reduced carbon footprint processing.

Further to this, we are pleased to share that CAN-ENG’s After Sales Service Team has been actively involved in supporting new and existing customers with system modernizing and repurposing for new demands and applications. Our After Sales Service team representatives have also been working diligently with our customers to develop alternate spare and replacement component strategies to ensure their production processing capacities are protected.

We hope that you find this of interest and look forward to meeting with you at CAN-ENG in the near future.” Tim Donofrio, Vice President – Sales, Can-Eng Furnaces International Ltd.

Did you like this article? Click here to subscribe to The Monty.

View our recent magazines and podcasts by clicking the following link. https://themonty.com/magazine/

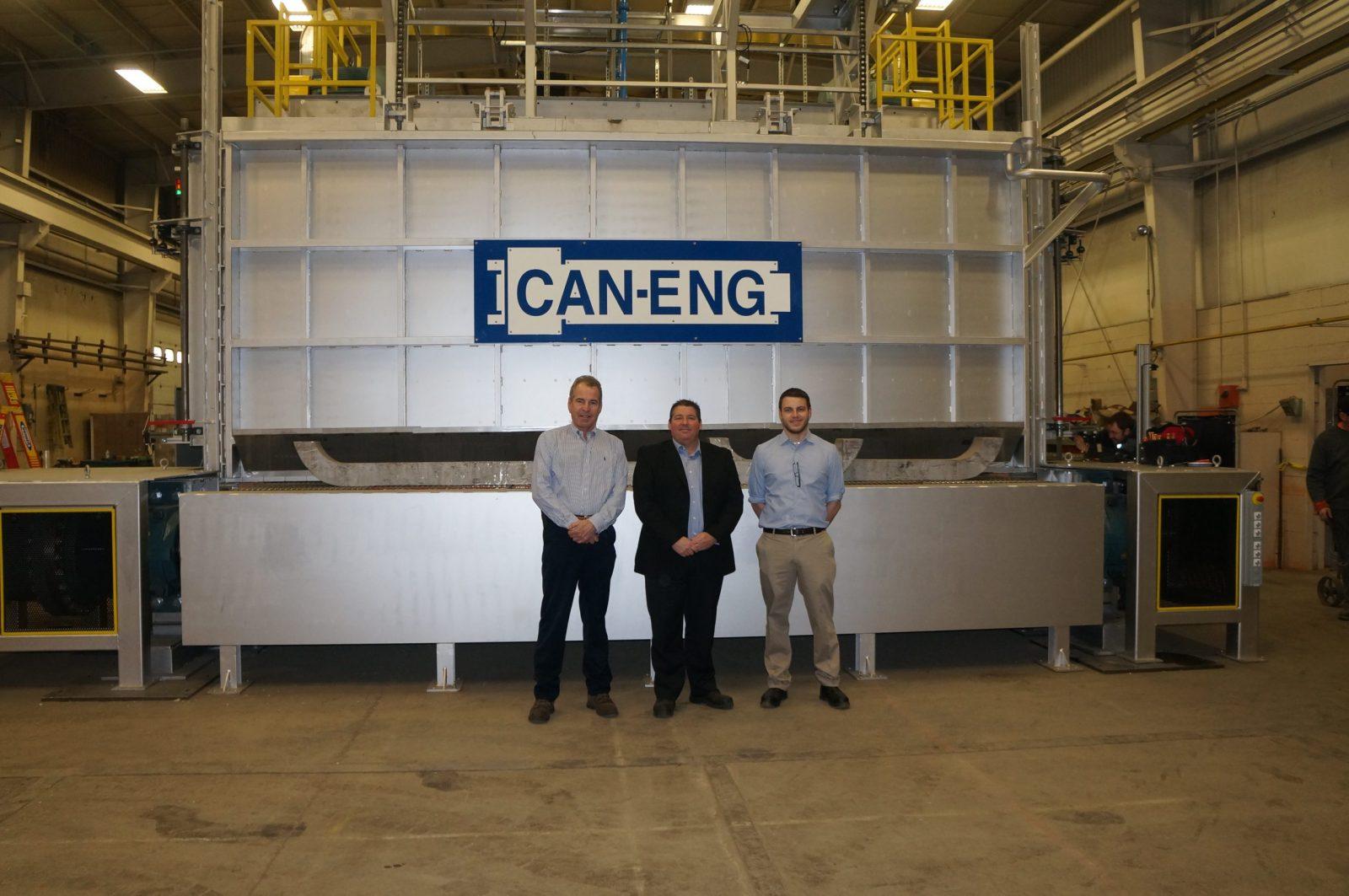

This picture was taken the last time “The Monty Heat Treat News” visited Can-Eng. From left to right you can see Gord Montgomery, Tim Donofrio, Jordan Montgomery.