Auto Parts Supplier Completes Installation of Brake Rotor Furnaces

Earlier this year furnace builder “Nitrex” announced with great fanfare that they had received an order from a European provider of automotive brake rotors for a semi-continuous FNC furnace (the original story can be found below and at “FNC of Brake Rotors-A New Approach”).

We can now say that the system in installed and ready for production-on time is our understanding which is impressive for what is a new concept.

“For a number of years now heat treating of automotive brake rotors has involved Ferritic Nitrocarburizing (FNC) in large tip up furnaces (generally but not always we will stress).

It would appear that “Nitrex” has come up with a different approach, one that will be in production in the very near future.

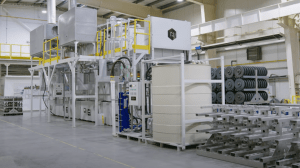

The furnace system you are seeing in these photos is in the final stages of testing at the Nitrex facility in Poland. The furnace is designed for around 600,000 rotors per year based upon 46 weeks/year, 5 days a week/24 hours a day with a “charge” every 2 hours. The furnace will be the first of two destined to be installed in Northwestern Europe. This system has exceeded all design criteria from heating rate, cooling rate and layer thickness/uniformity.

The furnace system you are seeing in these photos is in the final stages of testing at the Nitrex facility in Poland. The furnace is designed for around 600,000 rotors per year based upon 46 weeks/year, 5 days a week/24 hours a day with a “charge” every 2 hours. The furnace will be the first of two destined to be installed in Northwestern Europe. This system has exceeded all design criteria from heating rate, cooling rate and layer thickness/uniformity.As mentioned the system with be doing Ferritic Nitrocarburizing with consistent oxide layer and color.

In addition to these photos a video can be viewed below.

Did you like this article? Click here to subscribe to The Monty.

View our recent magazines and podcasts by clicking the following link. https://themonty.com/magazine/