Dominial Heat Treatment-The Interview

Today we are pleased to off this interview with Mr. Aad Hersbach, Director of commercial heat treatment company “Dominial” of the Netherlands. Dominial has a very interesting claim to fame and that is that they have some of the largest pit carburizing furnaces in all of Europe.

Today we are pleased to off this interview with Mr. Aad Hersbach, Director of commercial heat treatment company “Dominial” of the Netherlands. Dominial has a very interesting claim to fame and that is that they have some of the largest pit carburizing furnaces in all of Europe.

Aad while I have not yet had a chance to visit your plant you have given me enough details for me to realize that you have a very unique operation, consequently I have a long list of questions for you. Let’s start at the very beginning, with a history of your company-when the company was formed, ownership, goals etc.

My name is Aad Hersbach. I am the owner and director of Heat- treating Company “ Dominial “ . I have been running this family business for over 40 years and have been the owner since 1992. My goal was to build the Company by having the best possible quality, however delivering quality alone is not enough. So in addition to emphasizing quality we have also focused on having a very wide range of heat treatment processes combined with a short delivery time. Our investment in our very large pit carburizing furnaces was part of our strategy to be able to offer our customers every need they had.

My name is Aad Hersbach. I am the owner and director of Heat- treating Company “ Dominial “ . I have been running this family business for over 40 years and have been the owner since 1992. My goal was to build the Company by having the best possible quality, however delivering quality alone is not enough. So in addition to emphasizing quality we have also focused on having a very wide range of heat treatment processes combined with a short delivery time. Our investment in our very large pit carburizing furnaces was part of our strategy to be able to offer our customers every need they had.

How large is your company both in terms of sales and number of employees?

Currently we have 25 employees most of which have been with us for many years. As we are a family business, we feel that we offer a very personal touch to our customers.

You offer a number of different processes including nitriding, vacuum hardening, carburizing and induction to name a few but one area of your plant really caught my attention-you have some of the largest pit carburizing furnaces that I have ever come across in a commercial shop. You suggest that you can handle parts up to 20,000 Kg (45,000 pounds), which makes your company part of a very small group, could you please give us some details about the size of your furnaces and what products you run?

I am very proud of the fact that Dominial can offer a number of different heat treatment processes such as; Oil-hardening , vacuum hardening, carburizing, nitro-carburizing, nitriding, Induction-hardening, annealing, stress -relieving, blasting, etc.

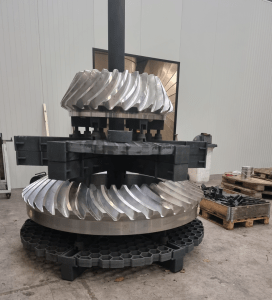

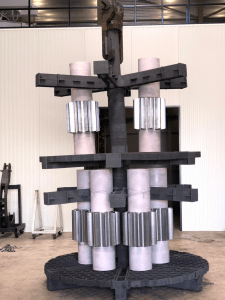

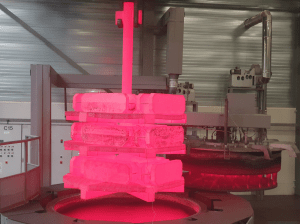

Over the past few years Dominial has expanded and installed 4 very large pit furnaces. Each has working dimensions of 2700 mm and a depth of 3500 mm (editor’s note this is roughly 106” diameter X 137” deep). Each can handle a weight of 20,000 kilograms per load (44,000 pounds). These furnaces are especially suited for carburizing very large parts such as gears which is our specialty. We feel these are some of the largest commercially available pit carburizing furnaces in Europe.

Have you ever been asked to quote parts that were too large for your pit furnaces?

We almost never have to say no to a customer because their parts are too large, as I mentioned few other companies have furnaces this large. Our working-area is generally western Europe, so transport is easy to manage. But if transportation is available, we can offer this heat treat process to customers all around the world.

We almost never have to say no to a customer because their parts are too large, as I mentioned few other companies have furnaces this large. Our working-area is generally western Europe, so transport is easy to manage. But if transportation is available, we can offer this heat treat process to customers all around the world.

Tying in with the previous question where do your customers come from? With the unique size of your furnaces, I would imagine you must get inquiries from around the world.

Several manufacturers of gears have long been important and loyal customers of Dominial, however we can never take anything for granted so we strive for the highest quality, with a fair price combined with a short delivery time. As we have become better known for our gear carburizing expertise, we had to invest in more large pit carburizing furnaces. What we now have are the largest in the Netherlands and some of the largest in Europe. In this era of energy transition there is an increasing demand from offshore energy projects to heat treat very large pieces. Quite often these products are part of big structures for wind power at sea, but we also treat parts for big cranes and ships. This market is growing and therefore Dominial is prepared and ready to measure up to fill all the heat treat demands of this growing market.

Dominial has several different departments offering different processes. These include vacuum hardening, induction hardening, gas nitriding, nitrocarburizing, blasting and stress relieving. Which process do you see as growing the most in the near future?

I would rather look at which market is growing the most rather than which technology. I would have to say that anything related to energy transition is very exciting. This is giving us a very interesting new market which was not a large part of our business in the past. We are very pleased to say that we have invested in the equipment necessary to do this and are ready for any new opportunities.

I would rather look at which market is growing the most rather than which technology. I would have to say that anything related to energy transition is very exciting. This is giving us a very interesting new market which was not a large part of our business in the past. We are very pleased to say that we have invested in the equipment necessary to do this and are ready for any new opportunities.

Energy costs. As a North American use to relatively low energy costs I am absolutely shocked to see what electricity and natural gas costs in Europe. How on earth are you managing these costs?

The cost of energy these days is a challenge to all of us. Cost varies from country to country and we are forced to use our energy very carefully. We try to be as economical and “innovative” as possible, and this requires a lot of attention and “good thinking”. Reusing energy as much as possible is a part of this mix.

Energy costs are only one of a number of challenges all industries are seeing these days. What is your number one concern these days, in other words what keeps you up at nights besides energy costs?

What worries me most is the instability in the world. When there is a war or a threat somewhere in the world today it will determine our future for a long time to come. That is why I think that it is very difficult to make your long term plans come true. I do know that heat treatment is absolutely necessary for manufacturing so as long as people around the world are consuming there will be heat treating.

What worries me most is the instability in the world. When there is a war or a threat somewhere in the world today it will determine our future for a long time to come. That is why I think that it is very difficult to make your long term plans come true. I do know that heat treatment is absolutely necessary for manufacturing so as long as people around the world are consuming there will be heat treating.

If you had a crystal ball, what would it be telling you about the heat treat industry in Europe? Do you expect significant changes in the technology being used? Consolidation within the commercial heat-treating industry-perhaps the large chains getting larger as the expense of smaller companies? Changes within the industry to reduce the number of employees? What do you expect to happen in the heat treatment industry in the next 5 years?

You must imagine that the Heat-Treatment of steel products has already existed for over 2500 years and during that time the principals of heat treating have not changed. You can refine the way you heat treat, you can automate to reduce the number of employees but I believe that hardening will remain pretty much the same as long as steel is being produced.

Aad I very much appreciate your thoughts and comments and hope to see your facility in person in the near future.

Did you like this article? Click here to subscribe to The Monty.

View our recent magazines and podcasts by clicking the following link. https://themonty.com/magazine/