CFC/Alloy Hybrid – The Next Generation Solution

With 100 years of experience in the design and manufacture of refractory alloy castings to the heat treatment market, the Cronite Group added machining and assembly of graphite and CFC fixtures to our product offerings in 1995. The Carbon factory in our Arnage, France plant produces a full range of products from graphite furnace parts to complex 3D CFC fixtures.

The design and R&D expertise of the Cronite Group continues to drive us into the future in our support of the heat treatment market. Our latest development is a new generation of products combining refractory alloys and Carbon materials to achieve the perfect balance of cost, strength, weight, and temperature/process resistance. This technology is particularly effective for vacuum heat treatment, atmosphere carburizing/hardening, and low pressure carburizing with gas or oil quenching.

The principle is simple. Combine the benefits of each material to maximize load size, life cycle, and process results all while minimizing cost. There are many aspects to be considered when designing the optimal hybrid CFC/Alloy fixture and the Cronite Groups expertise in design, alloy development, casting, machining and your heat treatment process allows us to develop and deliver the optimal solution. Distortion reduction, wear and abrasion resistance during loading/unloading, elimination of eutectic points, are just a few of the additional considerations taken when developing the most cost effective solution.

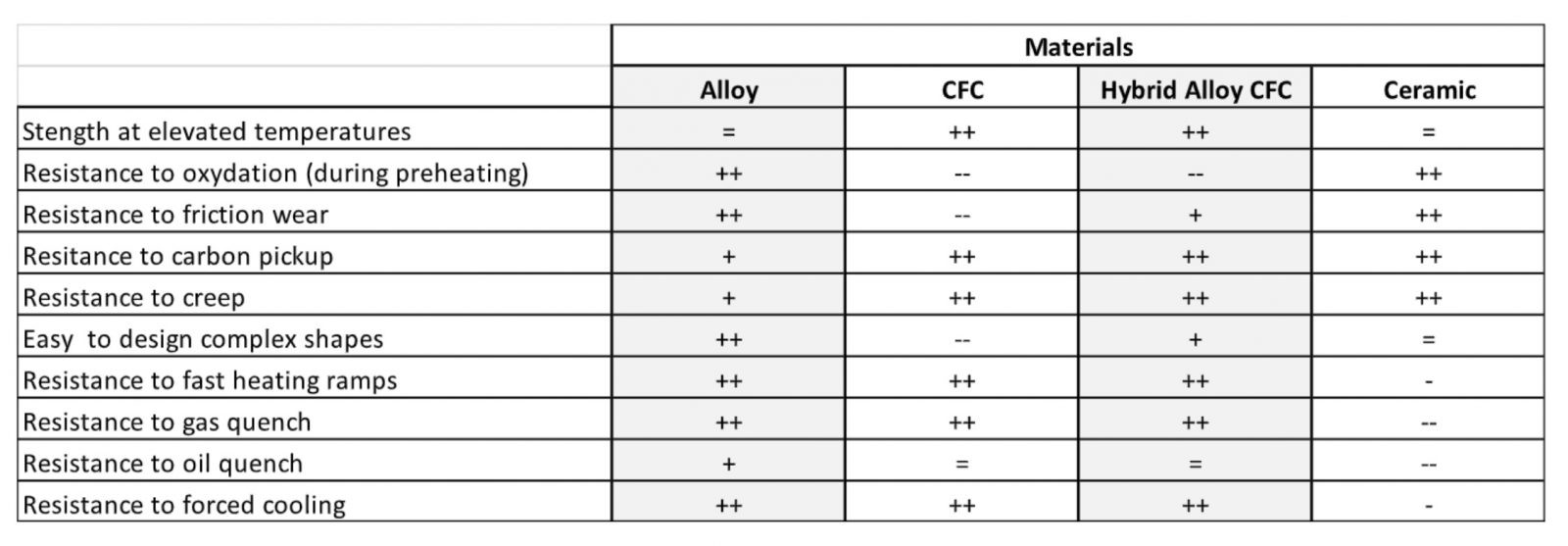

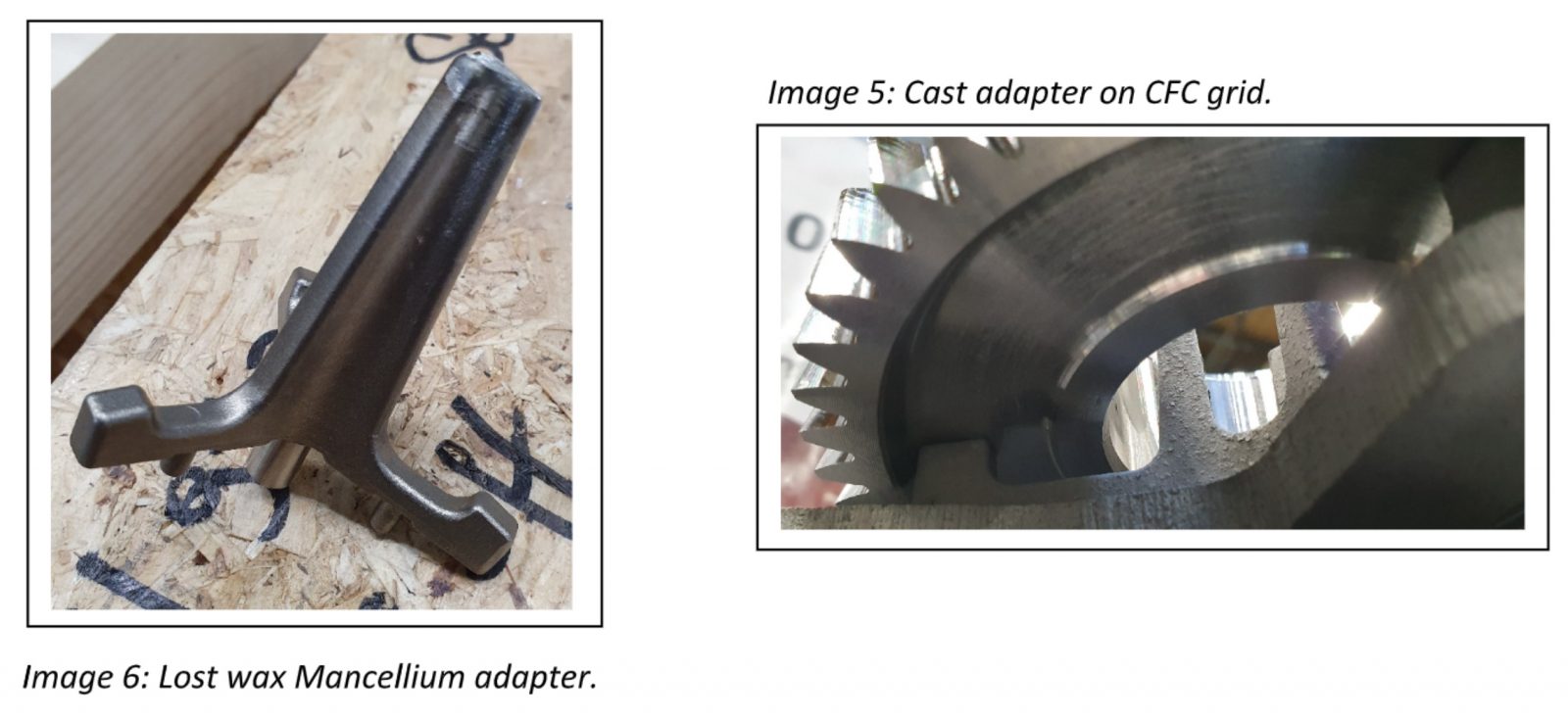

The following ring gear fixture example in low-pressure carburizing, illustrates the concept quite well. The base tray and the vertical grid are supplied as castings in Mancellium or our new proprietary carburization resistant CR alloys. An alloy base tray is better suited for the interface with the furnace internal material handling. The vertical support grid is also ideally suited for supply as a casting in one of our carburization resistant alloys (low dimensional change) due to the lower cost and direct load transfer to the base tray. The CFC arms provides greater strength elimination of creep deformation to support the overhung load of gears. This elimination of creep deformation is ideally suited for automated loading/unloading.

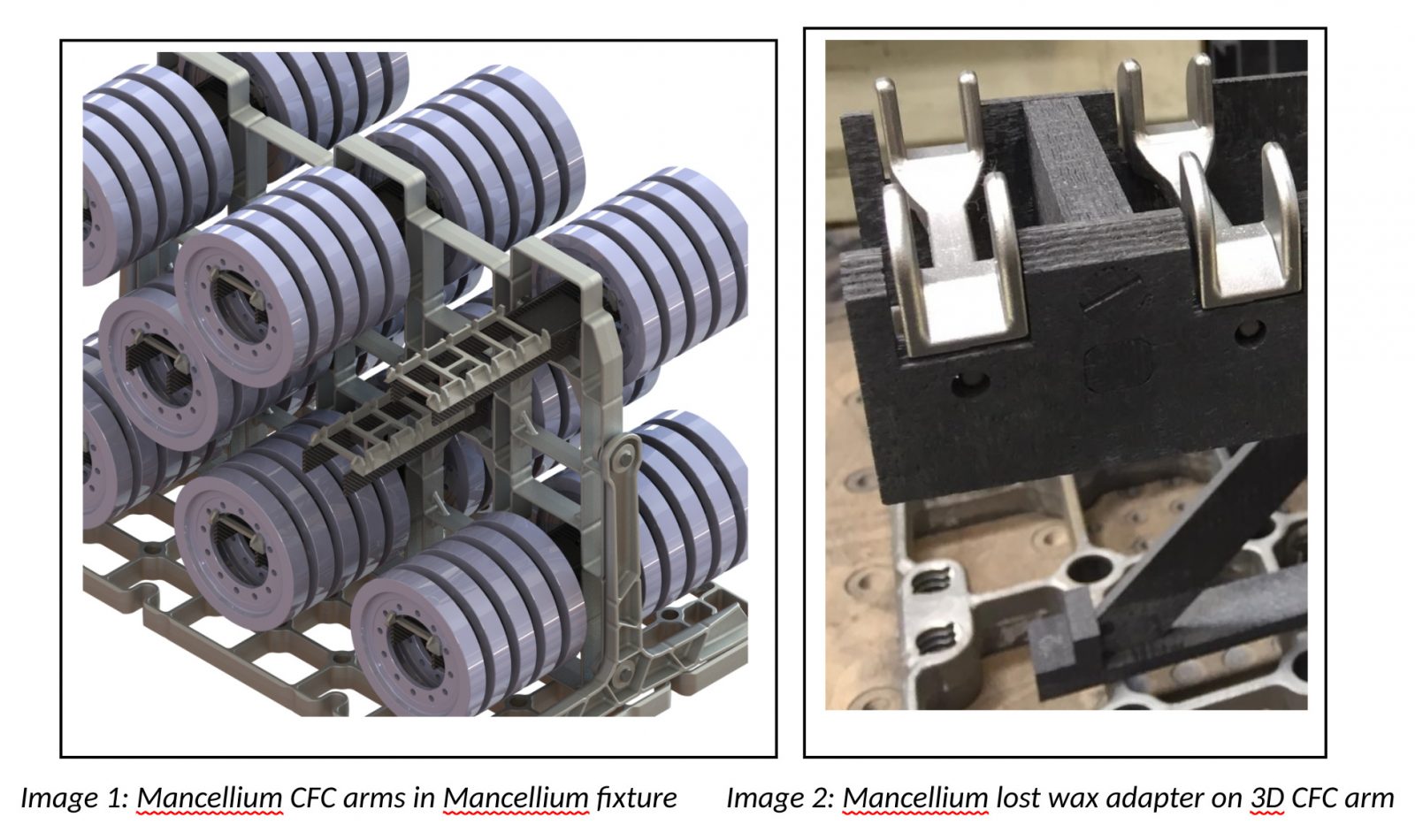

Part adapters are produced using lost wax due to the size and for the precision interface with the CFC arms without additional machining. Using alloy for the ring gear contact points eliminated abrasion wear on the CFC during loading/unloading.

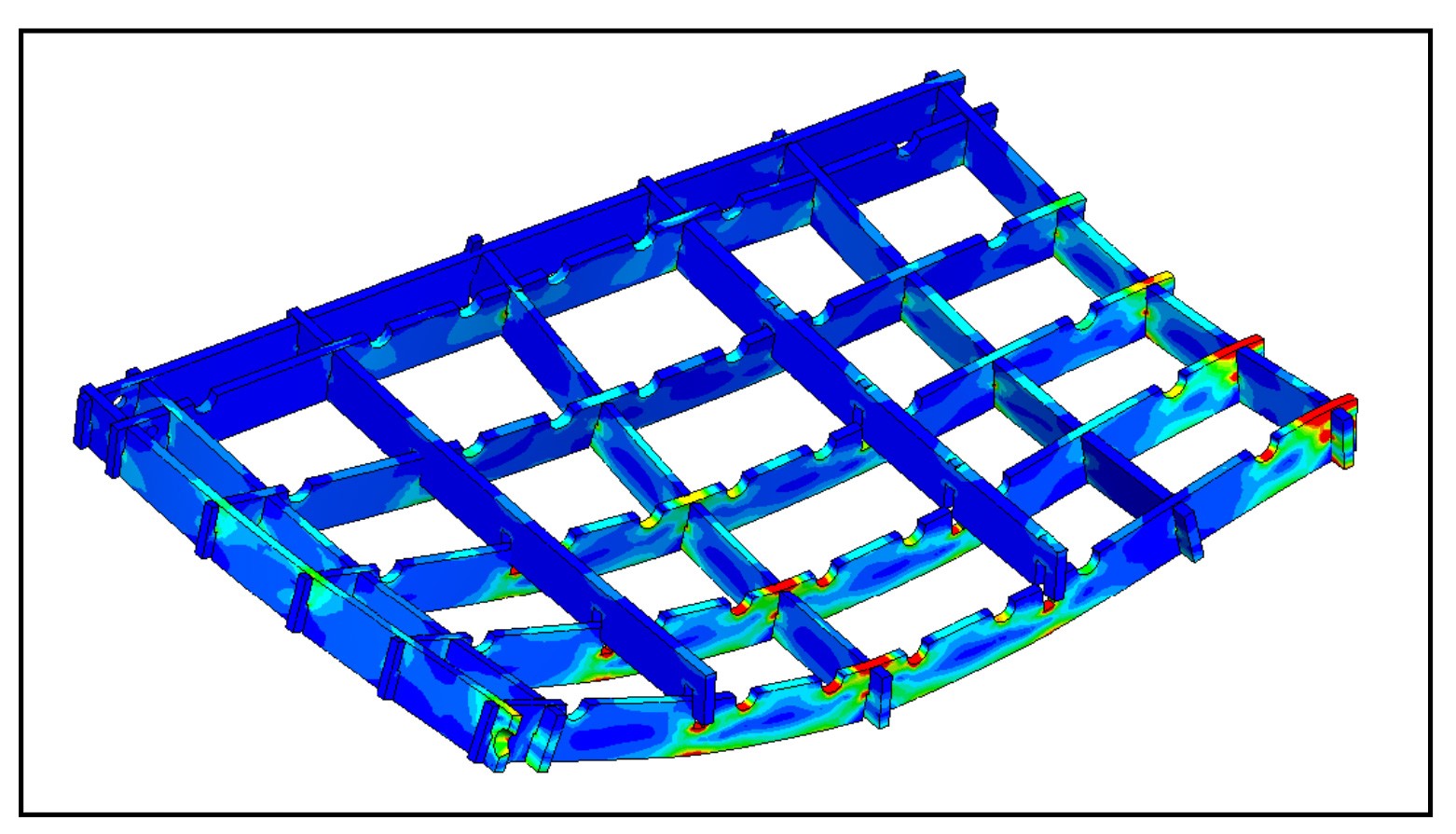

The Cronite design team utilizes Finite Element Analysis and Simulation-Driven Design software to ensure our solutions are perfectly suited for their application. Fixtures are optimized to maintain a high safety margin while reducing the use of expensive carbon composite elements. Use of these FEA and Simulation software tools for strength, creep, and deflection calculation allows our design team to rapidly develop fixture solutions with longer service life and reduction of customer part distortion during the heat treatment process.

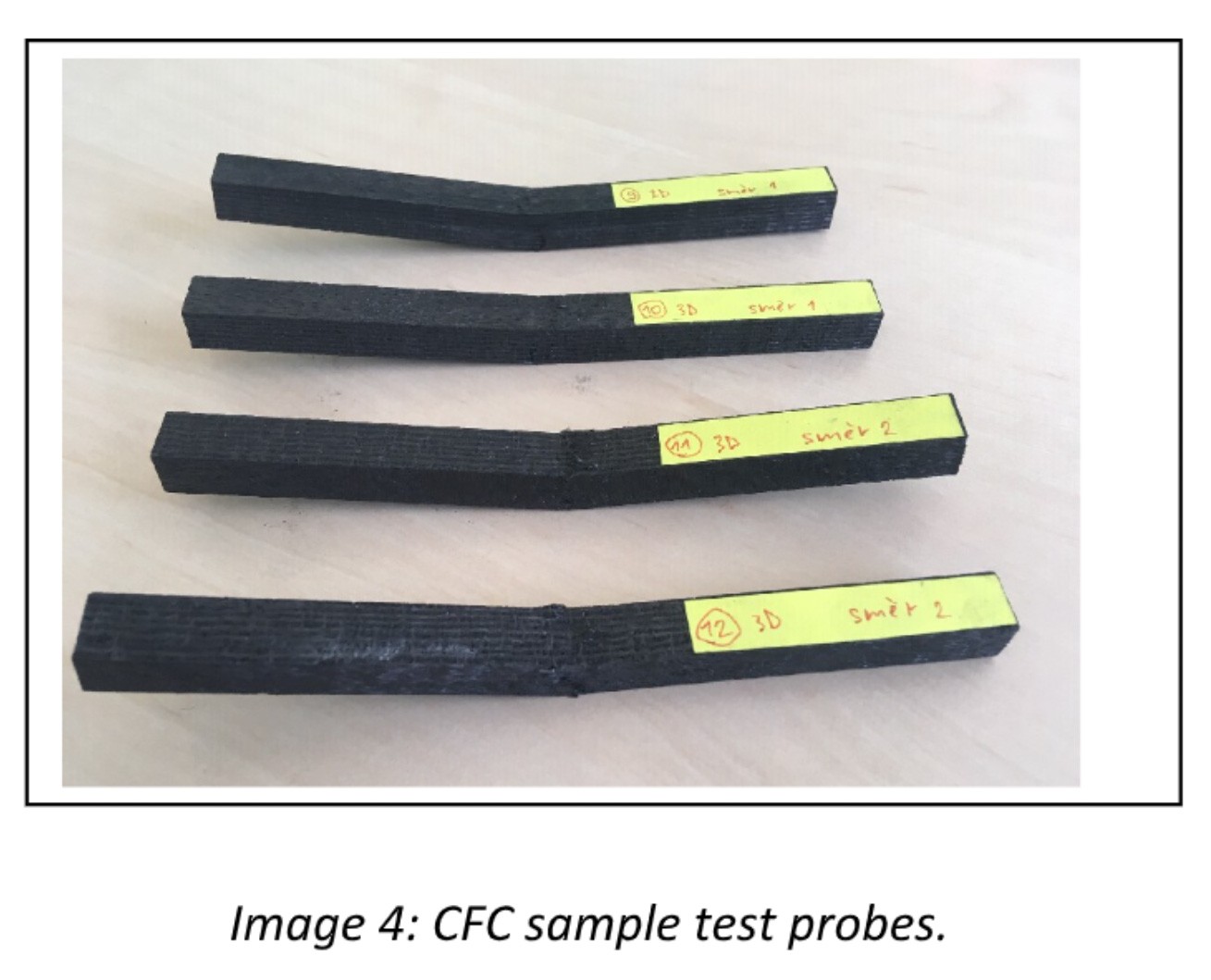

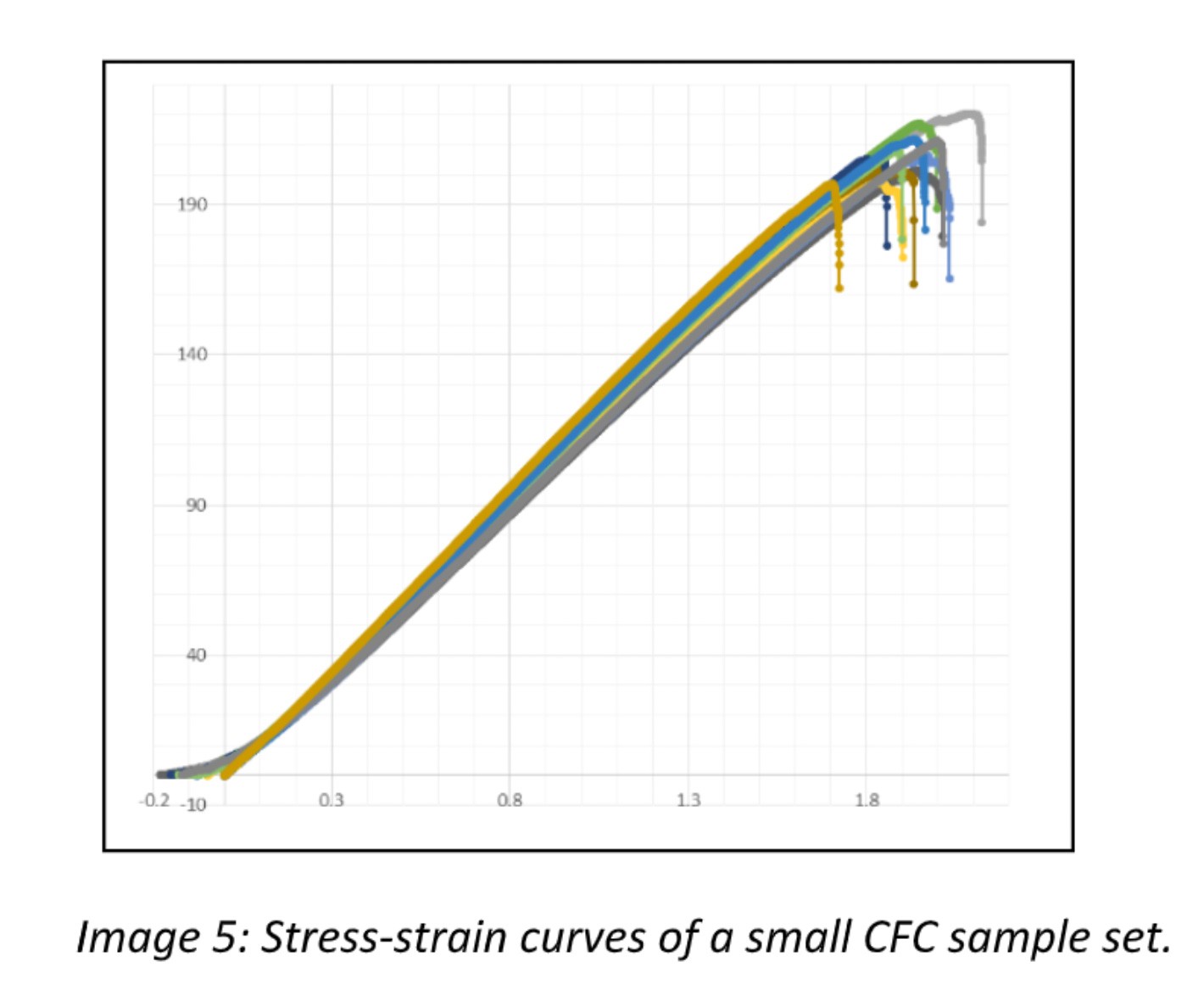

The Cronite Groups extensive R&D laboratory performs extensive destructive, fatigue, cycle, and environmental testing to confirm real world results match FEA methods results for alloys and relevant fiber orientation CFCs.

This independent analysis and testing of CFC materials has provided us an extensive and reliable material performance database for use in our computer modeling software and our selection of the highest quality CFC manufacturers.

As shown on the stress-strain image above, CFC materials exhibit exceptional strength and predictable deflection at elevated temperature. The material alone is not sufficient to guarantee satisfactory results. Parts must be properly supported and guided to minimize distortion which can be difficult or cost prohibitive with a CFC only solution. Our hybrid combination of CFC with cast alloy part supports solves this problem.

Our use of cast carburization resistant and non-stick materials like Mancellium and CR Alloys for the part contacting elements eliminates the potential of carbon transfer from the CFC to the customer part, eutectic points, and wear or fracture of the CFC surfaces during manual or automated loading/unloading. Cast alloy contact elements are also superior to ceramics as they are more resistant to the fast heating and cooling rates of the heat treatment process. Cast alloys also exhibit similar thermal growth as the fixtured parts, preventing another potential source of heat treatment distortion.

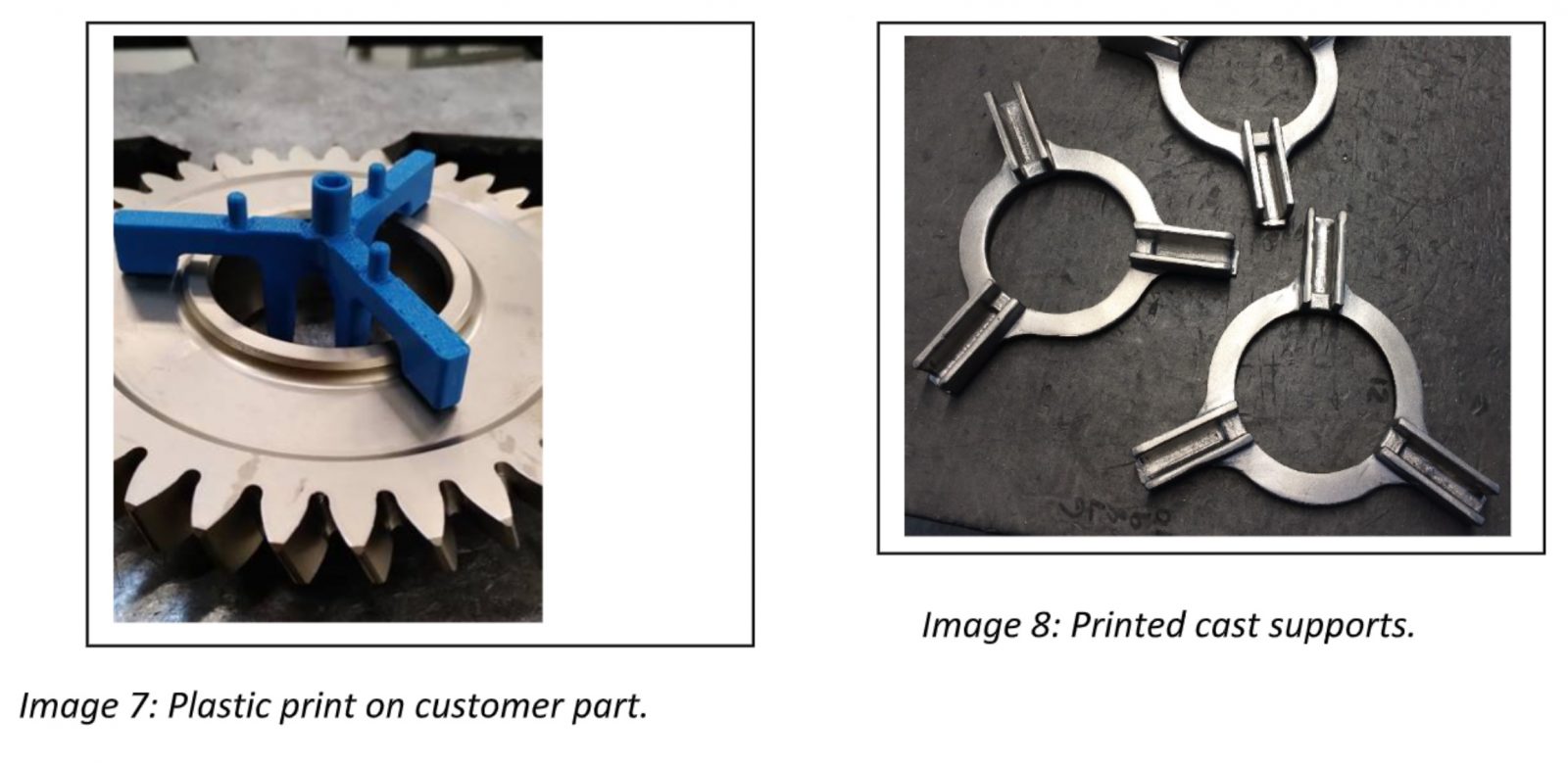

As Cronite employs multiple rapid prototype techniques and processes in our production facilities, we can deliver fixtures for benchmark and development testing quickly and cost efficiently.

3D printing of full-scale plastic prototypes provides our customers with visual and hands-on tools for confirming functionality, automation compatibility, and ergonomic use in the working environment prior to machining of the production pattern. We have adapted our 3D printing technology for use with lost wax compatible materials for rapid production of alloy fixtures for PPAP and heat treatment development projects.

This rapid prototype technology allows us to simultaneously produce and test multiple part support designs to quickly identify the ideal solution to minimize heat treatment distortion.

Cronite’s harmonization of the R&D, Design, and Production process in both alloy and CFC materials is the key to our success in optimizing our customers process quality while minimizing their operating and capital costs. Our unique combination of capabilities allows us to tailor custom hybrid solutions to your specific product and/or process. Challenge Us today to improve your bottom line.

Did you like this article? Click here to subscribe to The Monty.

Surplus heat treat equipment? Click here for a free appraisal and our help in selling it.