Carburizing of Large Gears – Haerterei Reese

Carburizing of large gears has been much in the news recently due to the closing in the USA of commercial heat treater Metlab who offered the largest commercially available pit carburizing furnaces in North America (https://themonty.com/metlab-ht-closing-giving-gear-suppliers-headaches/) As you can read in our original story it is quite possible that manufacturers of very large gears who lack the capability in house to heat treat might be forced to look as far afield as Germany which brings us to commercial heat treater Haerterei Reese.

“The Monty Heat Treat News” has been very familiar with the company for at least 15 years both as one of the largest commercial heat treaters in Europe but also due to the fact that they offer some of the largest pit carburizing furnaces in the world ( https://www.haerterei.com/ by the way Haerterei literally means “heat treater”). The company was originally formed as a gear manufacturer who incorporated heat treating in house, over the years this evolved to become strictly a commercial heat treater-Reese is a privately owned family business now in it’s third generation with co owners Philip and Julian Reese.

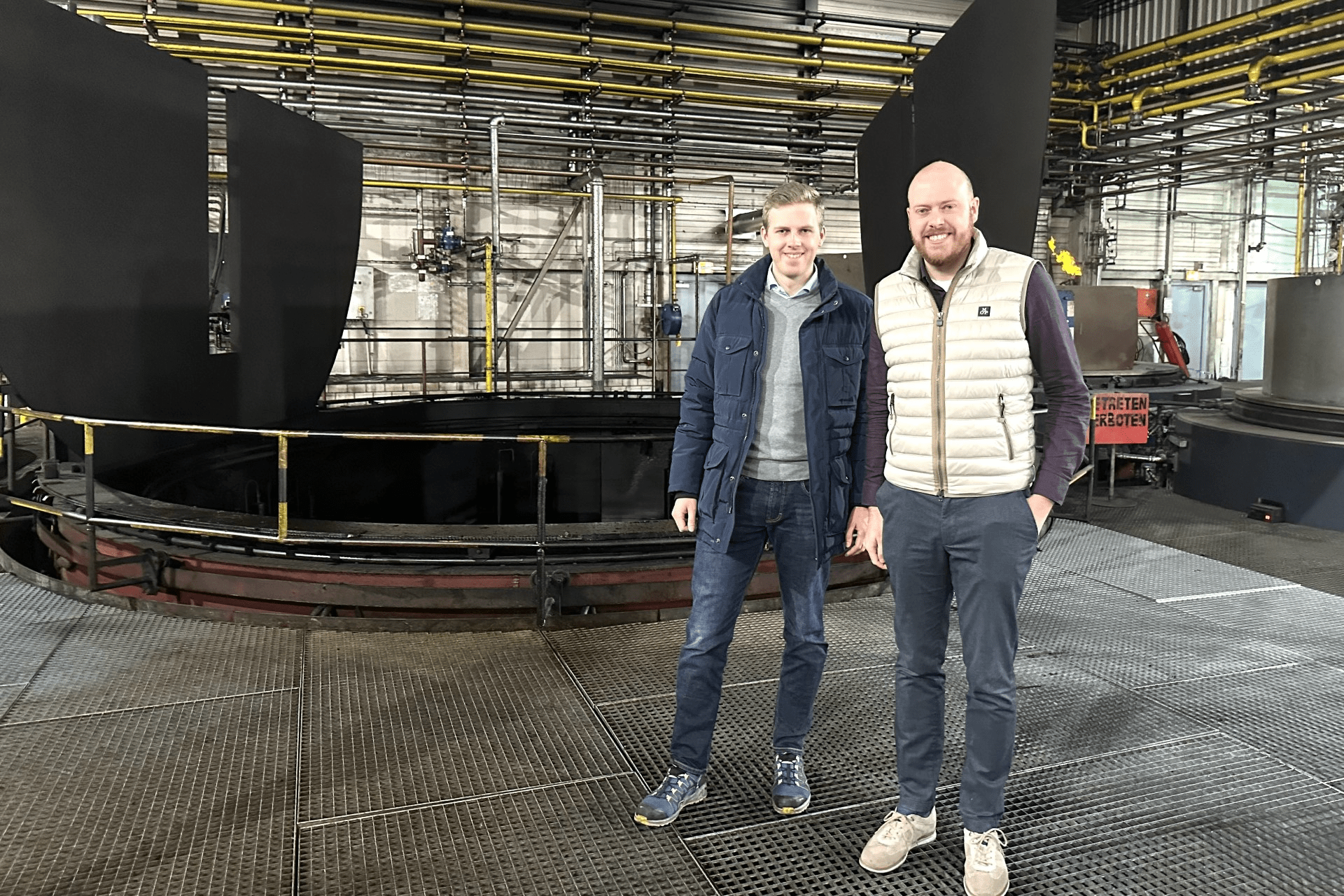

105,000 gallon quench tank. Julian & Philip Reese

Reese has 300 employees in 4 locations, the headquarters is in Bochum, Germany (which “The Monty” visited) with two facilities in eastern Germany largely involved in the auto industry and a fourth plant in southern Germany catering to the tool and die industry.

The centerpiece of the gear heat treatment department is a gas fired pit furnace with working dimensions of 5 meters in diameter and 5.5 meters deep (approximately 15’ X 16.5’ deep), working in conjunction with this system is a 400,000 litre quench tank 21’ in diameter and 21’ deep and pit temper units. Weight capacity is over 100,000 pounds. While this is the largest furnace Reese also has other pit furnaces capable of handling shafts up to 18’ long.

While the Bochum plant is best known for the size of their pit furnaces their induction heat treat is comparably impressive and able to handle shafts up to 11 meters (33’) in length. Currently the company is investing in a brand new Induction facility which will be located in a new adjacent building, when finished in 2 years this will be in total a 20 million Euro investment. Also in the works is a new induction facility in eastern Germany slated for January of 2025.

These photos don’t really do justice to the size of the pit carburizing facility but they at least give you an idea about how very large gears are heat treated.

Gord Montgomery, Julian & Philip Reese, Jordan Montgomery

Did you like this article? Click here to subscribe to The Monty.

View our recent magazines and podcasts by clicking the following link. https://themonty.com/magazine/