Bodycote Greenville, SC, USA Continues With Investment

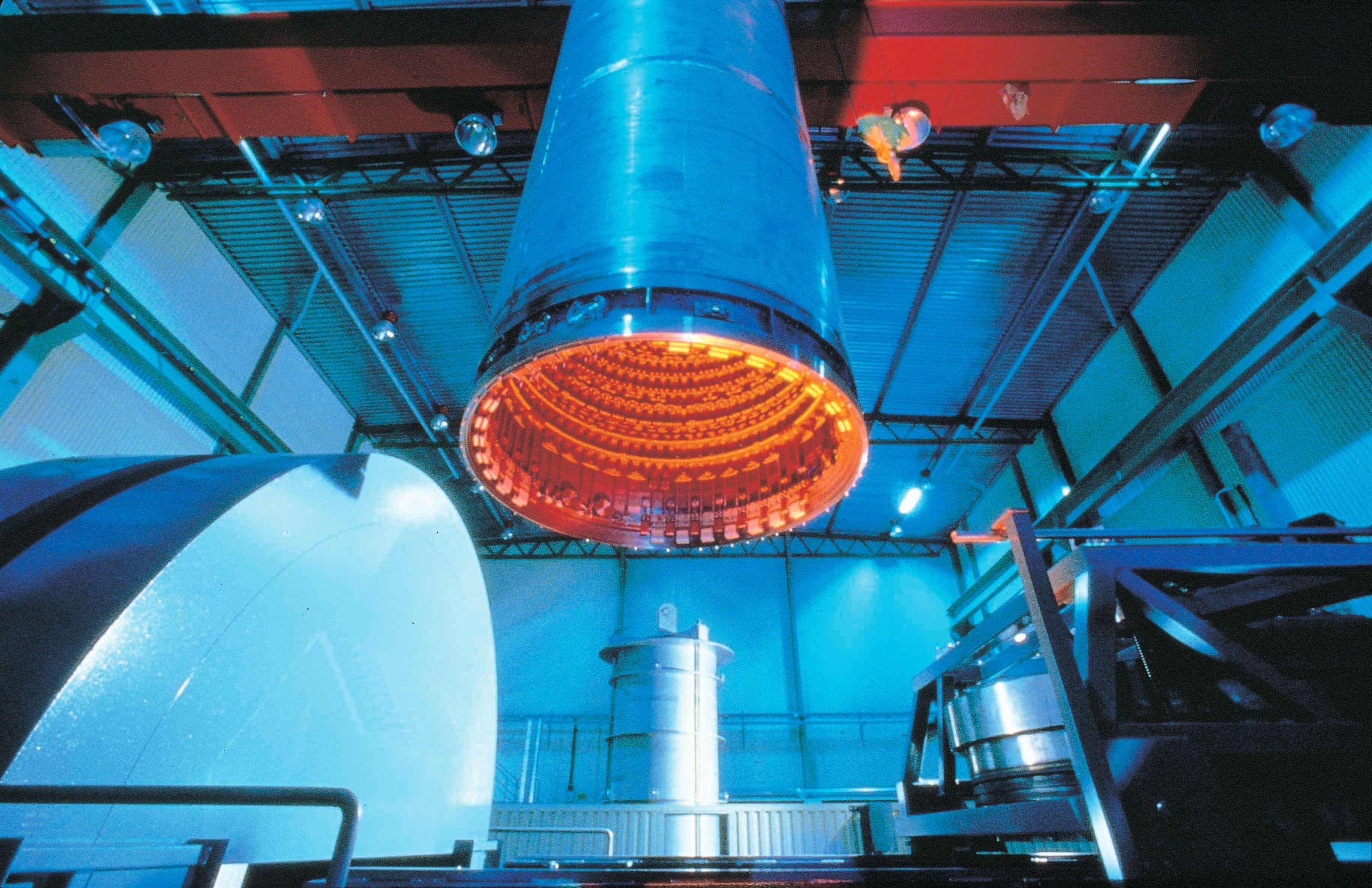

Going back to late 2021 heat treating giant Bodycote announced that they were investing in Hot Isostatic Pressing (HIP) capability at their facility in Greenville, SC, USA. This is the original press release; “November 2021; Bodycote increases Hot Isostatic Pressing capacity in the USA; Bodycote, the world’s largest thermal processing services provider, is expanding its Hot Isostatic Pressing (HIP) capability in Greenville, South Carolina, USA. The new HIP capacity will focus on developments in additive manufacturing and advanced materials. The two additional vessels further extend the company’s comprehensive range of installed capacity across the world. Bodycote’s Greenville, SC site is a Nadcap accredited site and holds several core OEM approvals. The site consists of numerous vacuum furnaces and other capabilities well suited to support our additive manufacturing customers. The Greenville site will serve the aerospace, defence, medical and general industrial customers throughout the Southeastern region.

Commenting on the increased capacity, Stephen Harris, Bodycote Group Chief Executive, said: “We are pleased to address our customer needs by bringing HIP services closer to their facilities. With the largest HIP operational capacity in the world, our continued investment demonstrates Bodycote’s commitment to align resources to serve our customers across North America.” Bodycote operates the world’s largest network of HIP equipment. Having established industry expertise over decades, Bodycote has more than 50 HIP vessels of varying sizes in multiple locations. Processing capability can accommodate components that are nominally up to 6.5ft diameter by 12ft high; and weighing over 30,000kg.”

This investment certainly reinforces the fact that the company is the largest in the world when it comes to HIP capacity. The project continues to move forward and the investment in this facility is certainly impressive with substantial improvements to infrastructure. At the same time our understanding at “The Monty Heat Treat News” is that long term plans for this facility include phasing out the atmosphere side of the plant. The atmosphere side includes several batch IQ furnaces as well as some continuous capacity. No firm date has been provided for this change.

Did you like this article? Click here to subscribe to The Monty.

View our recent magazines and podcasts by clicking the following link. https://themonty.com/magazine/