Pure Molybdenum vs. TZM For Your Vacuum Furnace Hearth – Part 1

We have an interesting news item today about why TZM alloy is better than pure Molybdenum for your vacuum furnace hearth. This is written by Bob and Ben Grammer of Grammer Vacuum Technologies, Inc.and their contact information can be found at the bottom of the news item. There will be a follow up as well so stay tuned for more information!

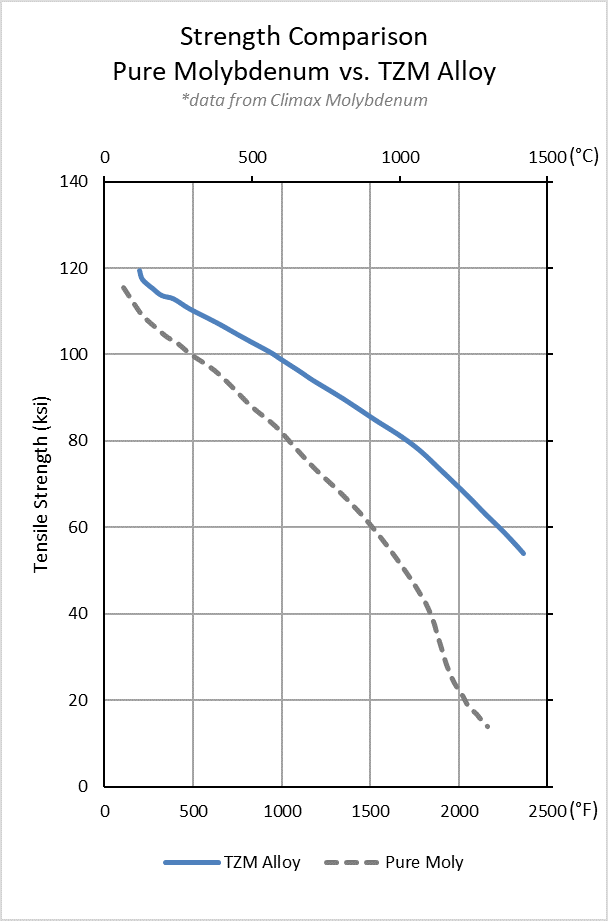

“In the case of furnaces with all-molybdenum hearths or of graphite hearths with molybdenum (“moly”) support posts, a direct replacement of those moly posts with TZM alloy moly posts will both increase strength of the hearth assembly and eliminate problems with recrystallization-induced embrittlement of the posts. (For an all-moly hearth, replacement of the horizontal load beams with TZM would have a similar benefit.) The comparative strengths vs. temperature of TZM alloy and pure moly are shown in the graph. Whereas at room temperature the strengths are very similar (around 110KSI-120KSI), once you exceed the 2000F recrystallization temperature of pure moly, the difference becomes dramatic. At 2000F the pure moly is about 40% of the strength of TZM alloy. By the time it reaches 2300F the pure moly is only about 25% of the strength of TZM alloy.

Not only is the TZM alloy much stronger than pure moly at temperature, but it also does not suffer from the same embrittlement problems. Pure moly, once it has recrystallized, forms very brittle grain boundaries in its microstructure. Its behavior begins to resemble that of glass. This is the primary mode of failure of moly components in vacuum furnaces – breakage due to intermetallic grain boundary embrittlement. TZM’s recrystallization temperature is around 2500F, and even when it does recrystallize, it forms very fine new grains that still have decent ductility. Hence, we recommend TZM alloy as a replacement for pure moly in all structural applications for vacuum furnaces. It is the “right stuff”.

Note that all metals used in a vacuum furnace, moly and TZM alloy included, will suffer from distortion due to the numerous thermal cycles they experience. Moly hearth beams are a good example. Once distorted moly hearth beams can be very difficult if not impossible to straighten without breaking them. To have any chance at all they must be heated to forging temperatures. TZM hearth beams however, due to their good ductility can often be heated to forging temperatures and successfully straightened. Most heat treating shops scrap out the moly hearth beams rather than even trying to straighten and re-use them. With a TZM hearth the hearth components can typically be re-used with a newly re-lined hot zone saving a large additional expense.”

Author: Robert Grammer, Grammer Vacuum Technologies, Inc. GVT provides an extensive inventory of Molybdenum and TZM alloy mill products for vacuum heat treating. To learn more: sales@gvtinc.com or visit www.gvtinc.com