Wickert Press Quenching-An Interview with Mr. Hans-Joachim Wickert

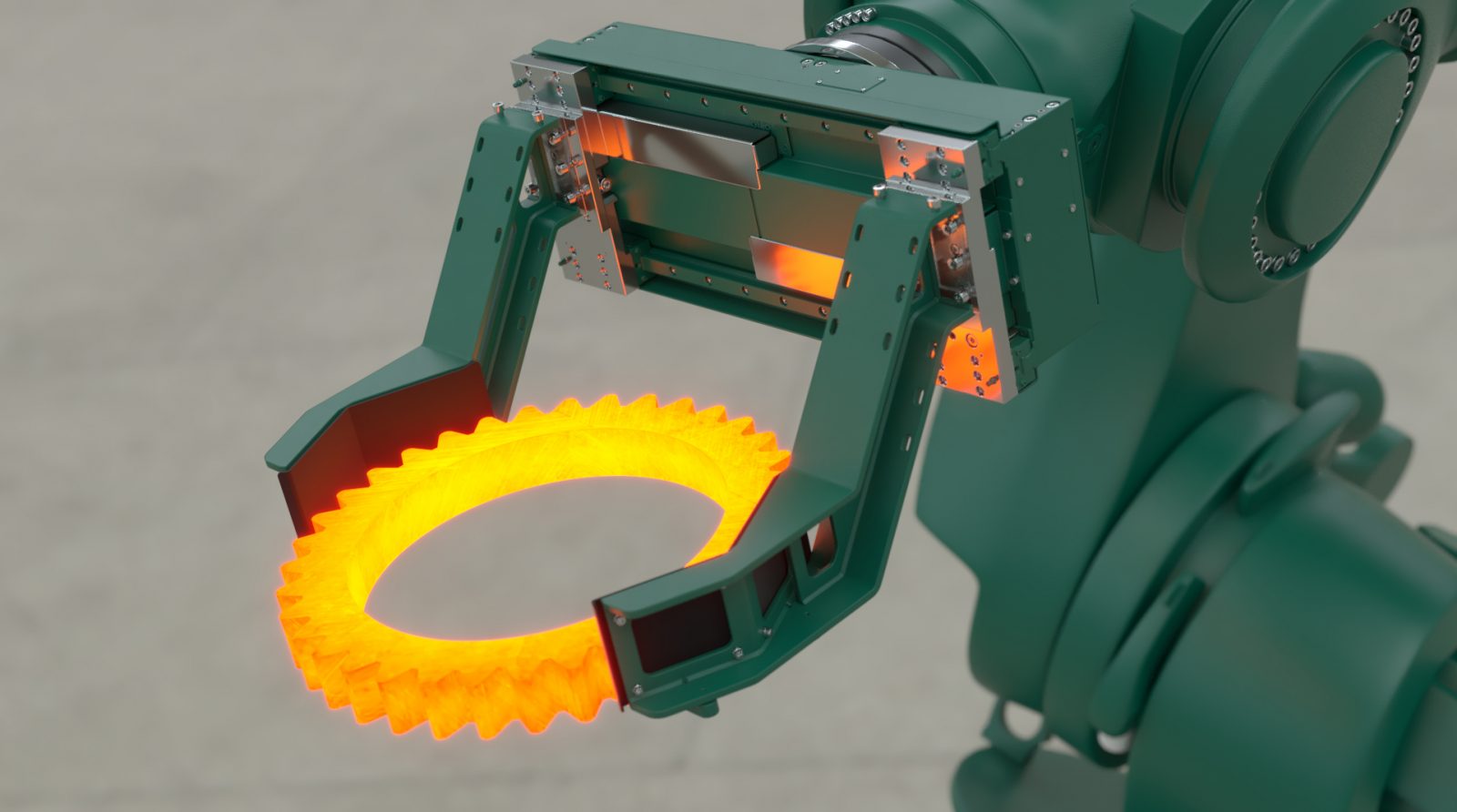

Press Quenching (also known as fixture hardening) has long been known as a technology to reduce distortion in parts and is typically found in captive heat treating departments of gear or bearing manufacturers. Today we speak with Mr. Hans-Joachim Wickert, Managing Director of Wickert Maschinenbau one of the leading providers of Press Quenching systems.

Press Quenching (also known as fixture hardening) has long been known as a technology to reduce distortion in parts and is typically found in captive heat treating departments of gear or bearing manufacturers. Today we speak with Mr. Hans-Joachim Wickert, Managing Director of Wickert Maschinenbau one of the leading providers of Press Quenching systems.

Lets start with some background about you and your company. Perhaps you could share with us the history of Wickert, the size of the company and your part in it?

“Wickert was founded in 1901 by Jakob Wickert, who was my grandfather. Originally he made forging presses for horseshoes. His business was located in the town of Landau which at the time was a garrison town which meant a lot of horses for the military which meant a lot of horseshoes. After the 1st World War, the Wickert company, located in the middle of a large wine-growing area, started making wine presses. This production continued until 1945, when it was gradually converted to industrial presses.

Today, Wickert employs 180 people, 25% of whom work in engineering and R & D. From this pool of qualified engineers the company today draws its innovative strength. From a company that only offered press quenches, Wickert has developed into a manufacturer who also offers complete turnkey systems for all aspects of presses. Today I personally take care of the sale of hardening systems and hardening presses and am the technical manager for the company.”

When I think about Wickert I think of press quenches but I realize that is probably unfair as the press quench is only a small part of what you have to offer. It would probably be more fair to say that you offer complete heat treatment solutions with press quenching being one part of a complete system. What would a typical Wickert Heat Treatment system look like and consist of?

If required, deep-freezing stations can also be integrated into the production process for the complete conversion of residual austenite. All components of the system are incorporated into the Wickert control system. This would include part tracking, process data, datalogging and complete control of the entire system. Interfaces to the customer’s own computer systems are programmed according to customer specifications. Statistical process control enables the customer to set his individual test levels. Wickert thus supplies turn-key systems for component hardening in gear manufacturing with the corresponding planning and deadline tracking capacities.”

Do you manufacture everything? For instance do you build the automation, furnace and associated equipment or do you partner with other companies?

“In order to be able to offer complete systems, we always purchase additional furnaces, blasting machines etc., or the customer provides them and we integrate them into our system control. At the end of the day Wickert provides the total design and is responsible for co ordinating all mechanical and electrical interfaces, start up and project management.

All automation including handling and loading of parts are designed and manufactured by Wickert. In addition Wickert designs and builds the washing systems, press quench itself and oil return system. It would be fair to say that a complete system is designed and built by Wickert, with some components coming from outside suppliers.”

At this point lets talk about press quenching in some detail. Press quenching is a very high end process and not something that most heat treaters run across on a daily basis. Why would a manufacturer consider this process and what are the most common applications? As an example are you going to see your equipment in automotive transmission applications or would it be more common to see a Wickert system in a bearing facility?

“Lets look at manufacturers of gearboxes and bearings as an example. Manufacturers of gearboxes know that the service life of a gearbox depends upon the precision of each individual component. In addition the efficiency and associated fuel savings also depend upon the precision of each part. The same holds true for bearings, precision is crucial to reducing friction and also reducing weight while maintaining the same performance. In this age of ever more powerful, lighter and environmentally friendly drives, process-safe precision in particular plays an increasingly important role for each component.

To achieve this precision, the parts are hard machined after hardening. As hard machining is expensive, the aim is to reduce this as much as possible. This is made possible by reducing the distortion of the components during hardening to a minimum. The avoidance of distortion results in a reduction of the hardening depth in addition to the reduction of hard machining. All in all, this is also a contribution to a more climate-friendly production of these components. This is why press quenching is so popular in the bearing and gearbox industries-we are able to reduce distortion which reduces hard machining.

The most common method used in gear manufacturing is the so-called mandrel hardening. With this method, the component is shrunk onto a fixed mandrel and thus maintains its roundness and cylindricity. At the same time, hydraulic hold-down devices such as press quenching act on the component to ensure the axial run-out of the component.”

If distortion is the main reason to use press quenching the next obvious question then is what sort of distortion levels can you achieve?

“While most people think of reducing distortion as the main advantage of press quenching this is not entirely true-metallurgy is also a very large factor. Press quenching can create a homogeneous microstructure property in the part by a targeted flow of the quenching medium to the component. This is of enormous importance, especially in the case of mechanical stress and/or wear resistance.”

What are the largest and smallest parts you have ever processed?

“The largest parts that we have hardened in a press quench so far have a diameter of 1 m (3’) and a weight of up to 75 kg (165 pounds). The lightest part, on the other hand, weighed only a few 100 grams. When it comes to an entire press hardening system, the largest components measured 1300 x 1400mm (51” X 55”) and had a sheet thickness of up to 150mm (6”)with a component weight of more than 100kg (220 pounds).”

We have spoken about your systems, where they are likely to be found and why a manufacturer would invest in the technology, now lets switch gears slightly and look at the overall market. Would you care to hazard a guess as to how many systems using press quenching are in operation around the world?

“This question is very difficult to answer, as there is a very wide range of applications for press quenching. Therefore, the question cannot be answered in general. But I would guess that there are several thousand systems in operation worldwide, if you include all types and styles of press quench machines.”

Is this a growing market? There are a number of processes available which claim to be able to significantly reduce distortion, bearing that in mind is press quenching growing in popularity?

“The press quenching business is not a growing market, at least not currently. This is not because of press quenching technology, rather a changing market. Largely this is because drive technology is moving away from the internal combustion engine and more and more towards electric drive. Nevertheless, we believe that our systems offer technological advantages over other technologies and that we have the right solutions in the drawer, especially for recording all process parameters in the sense of Industry 4.0.”

Where are the markets for your technology geographically? Being based in Germany I would assume your largest market is in Europe, but beyond that do you do much in Asia or North America? I know that recently we had a press release about a new sales office in the US which caught our attention.

“Yes that’s correct. The European market is the most important market for Wickert next to North America. Especially in America we see a good chance for Wickert to sell more press quench presses and press quenching systems. Therefore we have established a new sales office in Hebron, Kentucky. Our sales manager, Matthew Stachel has been active since January 2020. He is supported by a very experienced service technician who takes care of the after sales service of our machines.”

There are a lot of challenges in the world these days ranging from COVID 19 to growing protectionism to shifting markets. As Managing Director of an international company what do you see as your greatest challenge these days?

“As managing director of a family-owned company, you have to think long term. That is why Wickert is using this period of slower economic development to push ahead with its own technological developments and innovations. By advancing our technology now we will be able to help our customers in the future. In spite of the current political climate I don’t believe that protectionism will hinder us in the future. On the contrary, I think that volatile markets will demand much more flexibility and as a medium-sized enterprise, we can demonstrate this flexibility very well.”

What has 2020 been like for Wickert in terms of sales? Good? Bad? Indiffirent? And what would your prediction for 2021 be?

“In terms of new orders 2020 has been weaker than 2018 and 2019. Having said that Wickert has a very broad base and supplies presses and lines to many different industries. This broad base has so far helped us through the crisis. While it is very difficult to make a forecast for 2021, we are preparing for another weak year.”

Hans-Joachim I appreciate your time today and look forward to a time when we can sit down together and talk in more detail.

“Finally, I would like to thank you, Gord, for giving me the opportunity to report on Wickert Maschinenbau GmbH.”

Did you like this article? Click here to subscribe to The Monty.