AMETEK Hughes-Treitler-a Story of Vacuum Aluminum Brazing

The Aerospace Industry is built on the ability to deal with extremes.

For example, at cruising altitudes, in the thinner air between 30,000 and 42,000 feet, the atmosphere outside of a commercial airplane can range from -20 °F to -67 °F.

Meanwhile, well-maintained aircraft jet engines running near maximum thrust levels can generate temps as high as 4100 °F within the combustor.

When it comes to dealing with such extreme temperature contrasts, AMETEK’s Hughes-Treitler division specializes in engineering and manufacturing advanced heat exchange systems designed to fortify aircraft engines against these extremes.

“We manufacture some of the highest performance heat exchangers in the world,” declared Chris Woods, Senior Manufacturing Engineer at AMETEK Hughes-Treitler. “Our longstanding knowledge of the products and history of manufacturing them have given us the experience needed to deliver impressive heat exchange rates within a remarkably small footprint.”

And for years, they’ve relied on Ipsen to provide them with the heat-treating solutions they need to deliver high-performance parts that can withstand these extreme temperatures.

Hughes-Treitler and AMETEK

Hughes-Treitler was established in 1947 as a precision sheet metal manufacturer in Garden City, New York. After World War II, while the immediate need for military aircraft waned, there was growing demand for commercial aircraft as Americans increasingly sought opportunities to travel. United Airlines began daily scheduled service between San Francisco and Honolulu, and Pan-American World Airlines started offering commercial flights around the globe.

Over time, Hughes-Treitler evolved to focus on designing and delivering heat transfer solutions tailored to the growing commercial aircraft manufacturing industry. As the company grew, Hughes-Treitler expanded into the defense sector, contributing to military aircraft programs. Together with companies like Airbus, Boeing, and Northrup-Grumman, they collaborated to advance innovations in thermal management needed to keep making aircraft faster, more efficient, and for commercial fliers, more comfortable.

In 2004, after more than fifty years serving the aviation industry, Hughes-Treitler was acquired by AMETEK, complementing the company’s advanced aerospace technologies and solutions. AMETEK was founded in 1930 as American Machine and Metals, changing their name in the early 1960s to better reflect their focus on manufacturing analytical instruments, precision components and specialty materials.

Plate Fin Heat Exchangers

Some of the more common parts that can be spotted at AMETEK Hughes-Treitler are plate fin heat exchangers. The first impression of a plate fin heat exchanger draws comparisons to a car radiator.

“Plate fin heat exchangers are like car radiators, except the radiator in the car contains its fluid with more simple straight walled passages,” explained engineer Chris Woods.

Plate-fin heat exchangers are one of most compact heat exchanger architectures. Outside of aerospace applications, they can be used for cars and HVAC systems. Just like in a car radiator, plate fin heat exchangers typically cool down a liquid using air.

“What we do is more like creating a box where the hot fluid is inside the box, four sides are extruded bar, while the top and bottom are cladded parting sheet with embedded brazing material within it. The box is built around the fins to contain the fluid, and the fins extract the heat out into the cold pass.”

A plate fin heat exchanger is comprised of layers of corrugated sheet metal and braze-cladded parting sheets. When placed in an Ipsen furnace, the braze cladding melts and fuses the core together. The fluid and air can then transfer heat inside this core.

The heat exchanger keeps other moving parts and flowing fluids, like oil, at appropriate temperatures within the system so that the jet engine with its thousands of moving parts can continue to operate at peak performance.

Heat exchangers also help keep the cabin and the cockpit warm at these high altitudes. “Everything has a safe operating temperature,” Woods noted. “When a customer comes to us with requirements, we’re capable of proposing great solutions. We design and manufacture products that are frequently exclusive to those customers.”

In jet engine applications, heat exchangers are essential for managing heat from friction and waste heat from electronics, enabling critical systems to function reliably and efficiently.

Identifying Thermal Processing Solutions

A significant part of the process of developing heat exchange technologies was finding innovative brazing techniques. “We have pictures from within our facility in older versions of the Aluminum Brazing Handbook from the 1980s,” explained Woods. “In it, you can see the salt-dip brazing that we were doing at the time.”

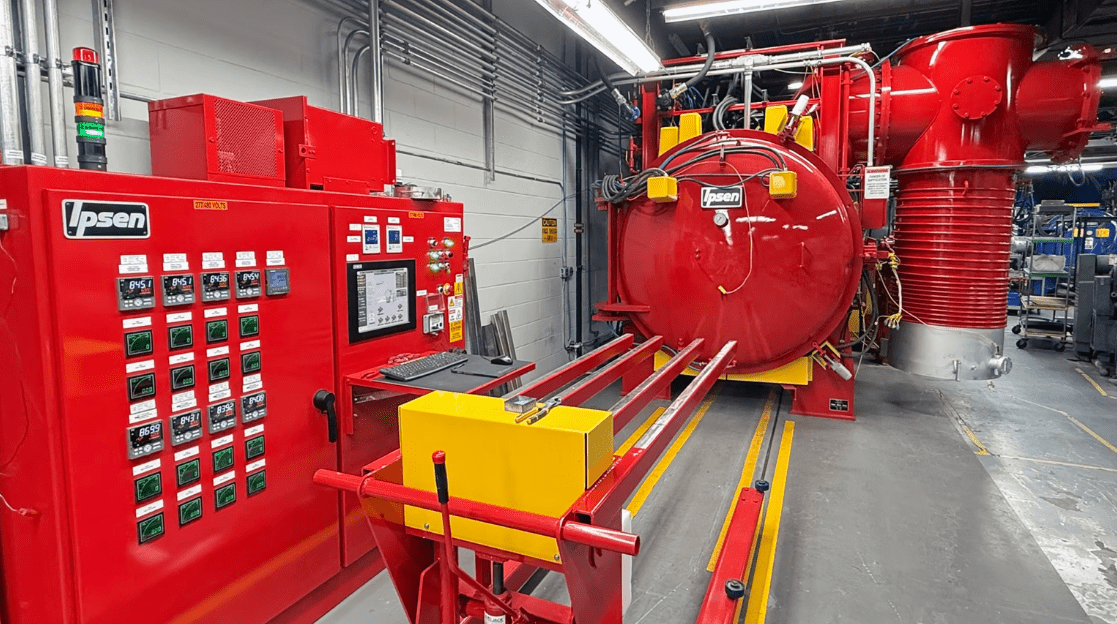

These days, the company is working with more than just aluminum. Inconel brazing is one of several processes running in one of the seven Ipsen vacuum furnaces at the plant. The furnaces line the heat-treating department in bright colors, their most recent addition – a striking fire-engine red Ipsen Vacuum Aluminum Brazer. “It’s too easy to be bland and pick a boring color,” Woods said with a laugh.

“We chose red as it represented AMETEK, but it’s also a fun color that stands out in our department. It makes people happy and gets people talking.” From a practical perspective, the colors also help Woods differentiate several furnaces that are closely packed together. “It’s much easier to differentiate the equipment. With bright colors, you can visually see where one furnace ends and where the next one starts.”

Several more Ipsen vacuum furnaces are operating simultaneously in AMETEK’s sister facilities in Mexico. Woods shared why Ipsen furnaces are AMETEK’s first choice for vacuum heat-treating equipment.

“We need to adhere to Nadcap AMS2750H standards, and Ipsen does a great job with the legwork. The controls are foolproof, and compliant to the standards in ways that help us calibrate the equipment easily to meet the requirements.”

Woods also shared that the Ipsen PLC interface was a significant factor when choosing their furnaces. “You can quickly train an operator to run a complicated piece of equipment doing a fairly complex process,” Woods suggested.

“It’s also nice having the same control systems across all facilities. Being able to troubleshoot minor issues and share knowledge with our colleagues in Mexico and Utah is very useful.”

And on the odd occasion when something stumps both teams? “We’ve been able to rely on Ipsen for keeping track of drawings and spare parts. The Ipsen Customer Support team has been very helpful. They encourage our self-troubleshooting and are open to taking a phone call and helping us work through a problem quickly. It’s a good dialog that way.”

In an industry that is built to handle the extremes, it’s important for Woods and the heat-treating team at AMETEK to know they can count on Ipsen for consistency and reliability.