Average New Vacuum Furnace Price/Largest Hot Zone Order-“Ipsen”

A Year Defined by Confidence and Growth

In 2025, Ipsen strengthened its position as a trusted partner for high-precision heat-treating solutions across critical manufacturing sectors. Continued demand from aerospace, defense, medical technology, advanced manufacturing, and energy markets reflected growing customer confidence in Ipsen’s ability to deliver quality equipment, responsive service, and dependable performance. Throughout the year, repeat orders from established customers, targeted investments in manufacturing and service capabilities, and a continued focus on training and education reinforced Ipsen’s long-term commitment to operational excellence and customer success. Together, these efforts created strong momentum heading into 2026.

Market Demand Driven by Precision and Reliability

High-stakes manufacturing sectors continued to expand in 2025, particularly in commercial aviation, space launch, defense, and power generation for data centers. Growth in data centers and AI-related infrastructure increased demand for rare-earth metals manufacturing, while continued innovation in electric vehicles and battery technology supported demand for lightweight and specialty metal components.

Broader economic trends also contributed to increased interest in in-house heat treatment as manufacturers sought greater control over quality, throughput, and delivery timelines. Customers investing in their own heat-treating capabilities increasingly looked for partners with deep process knowledge, proven reliability, and the ability to support long-term operational needs—areas where Ipsen’s experience and scale continue to differentiate the company.

Engineering Solutions Aligned to Customer Processes

Engineering Solutions Aligned to Customer Processes

In 2025, customers consistently chose Ipsen for its ability to engineer furnace solutions optimized for specific applications and production requirements. Rather than one-size-fits-all systems, Ipsen applies deep metallurgical and process expertise to help customers maximize throughput, efficiency, and long-term performance.

Ipsen also continued development of its next-generation furnace operating system, informed by how customers interact with their equipment in real-world environments. Scheduled for launch in 2026, the new controls platform is designed to deliver clearer, more intuitive visual interfaces that provide operators and maintenance teams with relevant information quickly and effectively.

Building on the success of existing digital tools such as PdMetrics, Ipsen continued enhancing the customer experience through improvements to online parts ordering and Ipsen Connect. These updates—driven by direct customer and internal feedback—are already helping customers identify and order replacement parts more efficiently, reducing downtime and simplifying routine maintenance.

Quality at Speed Drives Repeat Business

Ipsen’s Quality at Speed initiative continued to guide decision-making across manufacturing, service, and customer support in 2025. The result has been measurable customer confidence, demonstrated most clearly through repeat business.

Multiple established customers placed additional furnace orders throughout the year to expand their Ipsen fleets, citing consistent equipment quality, responsive service, interchangeable spare parts, and familiarity with Ipsen systems as key factors in their decision-making.

Investing in Knowledge, Training, and Expertise

Investing in Knowledge, Training, and Expertise

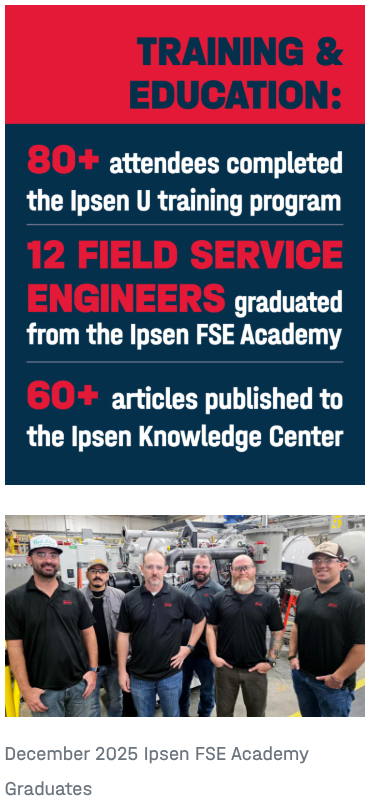

Ipsen continued to invest heavily in education and training programs in 2025 to support both customers and internal teams. More than 80 trainees completed in-house Ipsen U programs, while several customers scheduled on-site Ipsen U training to support their operators and maintenance personnel.

Twelve field service technicians graduated from the Ipsen Field Service Engineering Academy across two sessions, combining classroom instruction with hands-on experience to further strengthen Ipsen’s service capabilities.

The Ipsen Knowledge Center also expanded significantly in 2025, with more than 60 new articles published. These resources—ranging from technical guidance to customer stories—provide practical insights into heat-treating processes, furnace operation, and best practices, reinforcing Ipsen’s role as a trusted technical authority in the industry.

Continuous Improvement Across Manufacturing and Service

Continuous Improvement Across Manufacturing and Service

Ipsen’s commitment to continuous improvement remained a core focus in 2025, guided by lean manufacturing principles including Kaizen and 5S. At the Souderton manufacturing facility, investments in new CNC equipment improved accuracy and throughput, contributing to shorter lead times for customers.

Enhanced enterprise resource planning tools and a real-time manufacturing execution system improved visibility and planning across operations. These investments helped double hot zone output year over year while supporting the fulfillment of more than 4,000 parts orders out of the Souderton location in 2025.

Ipsen also continued expanding its Service HUB network, announcing its seventh active HUB and extending coverage to more than 350 customers across North America. HUB customers benefit from quicker response times, consistent technical support, and access to familiar field service technicians.

Additionally, Ipsen’s calibration laboratory successfully renewed its ISO/IEC 17025:2017 accreditation for pyrometry while investing in advanced pyrometry certification for ten field service engineers—further strengthening compliance, accuracy, and customer confidence.

Looking Ahead to 2026

As demand continues across aerospace, defense, data center, and advanced manufacturing markets, Ipsen enters 2026 well positioned for continued growth. Ongoing testing of the new furnace operating system, additional investments in manufacturing equipment—including a new fiber laser system—and continued expansion of service capabilities will further strengthen Ipsen’s ability to support customers worldwide.

That momentum is already evident early in the year. In the first month of 2026, Ipsen secured the largest equipment order in company history, awarded by a long-standing aerospace manufacturer with rigorous qualification standards and global operations. While the customer remains confidential, the order reflects decades of trust, proven performance, and Ipsen’s ability to deliver mission-critical thermal processing solutions at scale.

At the same time, Ipsen remains committed to investing in its people through professional development, targeted recruiting, and expanded referral programs. By growing teams in Cherry Valley, Souderton, and throughout the global service network, Ipsen is building the expertise and capacity needed to support customers today and into the future.

With a clear focus on Quality at Speed, technical excellence, and long-term partnerships, Ipsen is prepared to carry the momentum of 2025 forward into the year ahead.