Controlled Atmosphere Brazing Lines For China & Mexico

(AI Overview; CAB furnaces, or Controlled Atmosphere Brazing furnaces, are industrial systems that join aluminum components like radiators and condensers using a non-corrosive flux in a pure nitrogen environment, providing precise heating for high-quality, oxide-free bonds, essential for automotive, aerospace, and HVAC parts. These continuous or semi-continuous systems involve degreasing, fluxing, drying, and brazing stages, offering cost-effectiveness and high throughput for mass production, differing from vacuum brazing by using flux for certain alloys.)

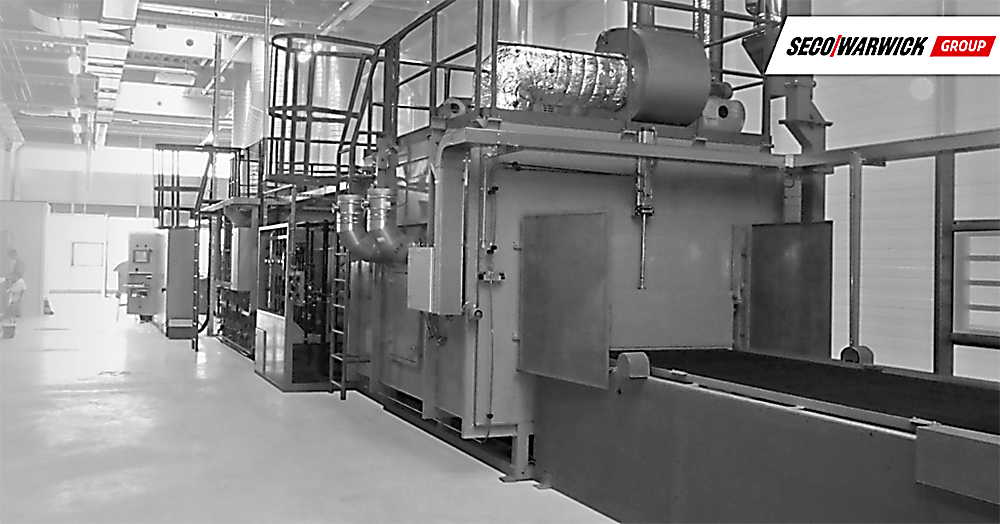

“SECO/WARWICK – a global expert in controlled atmosphere brazing technology – will deliver two EV/CAB lines for a long-standing Chinese Partner. One of the installations will be launched in China, and the other in Mexico. These are further orders confirming a strong, long-term technological partnership.

The story began 15 years ago, when the existing equipment was first used for the production of heat exchangers for trucks, passenger cars, and new energy technologies. The Partner has dominated the heat exchanger sector for years, being the first private company in the industry to be listed on the Chinese stock exchange.

The CAB furnaces on order were designed to meet the stringent requirements of the automotive industry for the production of components for commercial vehicles and to ensure long-lasting and reliable operation in demanding industrial conditions.

Both lines are modern aluminum brazing solutions dedicated to the production of key cooling system components for electromobility and classic automotive applications. The line with a belt width of 1900 mm, destined for the Chinese location, was designed for battery cooling plate production, while the 1800 mm wide line, which will go to Mexico, will be dedicated to the production of automotive heat exchangers.

“We are proud that one of the leaders in automotive thermal management consistently chooses SECO/WARWICK technology. Our CAB lines are proven, precise production tools for electromobility, which not only meets current market needs, but also fulfills future requirements regarding automation, efficiency and ecology. Recently, we celebrated the 15th furnace for the 15th anniversary of cooperation with this Partner. Now we can add two more devices to the list,” commented Piotr Skarbiński, Vice President of the Aluminum and CAB Product Segments at SECO/WARWICK.”

“We are proud that one of the leaders in automotive thermal management consistently chooses SECO/WARWICK technology. Our CAB lines are proven, precise production tools for electromobility, which not only meets current market needs, but also fulfills future requirements regarding automation, efficiency and ecology. Recently, we celebrated the 15th furnace for the 15th anniversary of cooperation with this Partner. Now we can add two more devices to the list,” commented Piotr Skarbiński, Vice President of the Aluminum and CAB Product Segments at SECO/WARWICK.”