“Top 15” Captive Heat Treater Adding More Capacity

“The Monty Heat Treat News” has always ranked auto parts supplier “American Axle & Manufacturing” as one of the “15 Largest Captive Heat Treats in North America”

“The Monty Heat Treat News” has always ranked auto parts supplier “American Axle & Manufacturing” as one of the “15 Largest Captive Heat Treats in North America” “Number 10 American Axle & Manufacturing Holdings (AAM), Silao, Mexico. In 2012 auto parts supplier American Axle & Manufacturing (AAM) formally opened a new location in the city of Silao, Guanajuato, Mexico. The Silao facility was AAM’s second manufacturing facility in Mexico, joining the Guanajuato Manufacturing Complex. The opening of these facilities marked a real change in the firms philosophy as previous to this most manufacturing was in the USA including a large facility in Buffalo, New York which featured 5 single row pusher lines. Each AAM facility (including Poland) has a varied mix of heat treating equipment which includes pusher furnaces, batch IQ’s and Induction to name a few. Each of the AAM heat treating departments is very impressive, mainly because they are relatively new and obviously no expense was spared. AAAM globally can be considered one of the larger captive heat treaters in existence.”

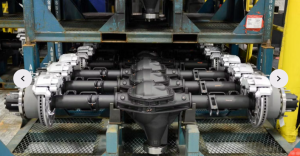

According to this press release from the company it would appear that the company is continuing to expand. These photos show some of the pusher furnaces at one of the AAM plants in Mexico. “American Axle & Manufacturing-15 Largest Captive Heat Treats North America”

“American Axle & Manufacturing has slated a $132.9-million investment to expand production at its Three Rivers, Mich., manufacturing plant, where it produces front and rear axles for automotive OEMs like General Motors, Stellantis, and Nissan. In its announcement, AAM stated it will be installing a new production line, and indicated the expansion will lead to new jobs at the southwest Michigan plant.

“American Axle & Manufacturing has slated a $132.9-million investment to expand production at its Three Rivers, Mich., manufacturing plant, where it produces front and rear axles for automotive OEMs like General Motors, Stellantis, and Nissan. In its announcement, AAM stated it will be installing a new production line, and indicated the expansion will lead to new jobs at the southwest Michigan plant.According to reports, improvements will be made to the plant structure and HVAC system, the wastewater treatment systems, as well as new machinery and updated production lines.

AAM did not detail the schedule for the expansion project.

“These investments are necessary to ensure our plant infrastructure and advanced manufacturing processes remain competitive, while supporting our highly skilled workforce,” stated Tolga Oal, president of AAM’s driveline division.

The Three Rivers plant produces front and rear axles, steering linkages, and AAM’s EcoTrac all-wheel drive system. The 123-acre plant has hot-, warm-, and cold-forging process lines, along with precision machining, heat-treating, and assembly operations.

Detroit-based AAM manufactures driveline and drivetrain systems, and related components at 11 U.S. locations and dozens more in Asia, Europe, and South America. The company is in the process of completing a $1.44-billion takeover of Dowlais Group, the engineering group that includes GKN Automotive and GKN Powder Metallurgy.”