How Do I Get a Consistent Linear Leak Rate Measurement? By Jim Grann Ipsen Technical Director and Janusz Kowalewski Ipsen Sales Director for Southeast Asia

“There is no such thing as a perfect vacuum. Even outer space has a few stray atoms and molecules floating around.

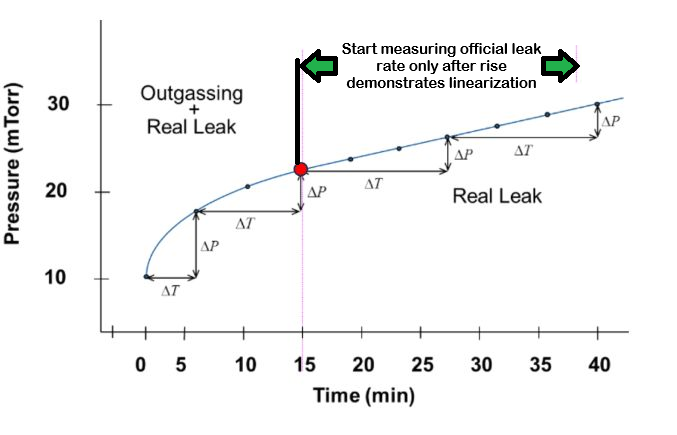

A linear leak rate measures the rate at which gas atoms or molecules enter the vacuum furnace when it’s isolated from the pumping system over time. In the U.S., it’s usually expressed in units like microns per hour (μm/hr) or Torr per hour.

Monitoring the linear leak rate in a vacuum furnace is crucial for maintaining vacuum integrity—essential knowledge to ensure a consistent, repeatable heat-treatment process. Proper leak rates ensure that your parts meet specifications, indicate whether your furnace has a maintenance issue, or explain why you may be dealing with part discoloration.

In some cases, operators seeking to establish a leak rate quickly will only sample 15 to 30 minutes to observe leak rate measurements. Extrapolating a short sample reading over an hour, particularly when that short sample may be at the beginning of a test, will rarely result in an accurate linear leak rate. Outgassing must be accounted for at the beginning of the test before one can paint an accurate picture of a furnace’s true leak rate.

The best thing to remember for your calibration testing is that the linear leak rates are reported not on a per-minute basis, but on a per-hour basis for a reason. There’s almost no reasonable way to determine a proper linear leak rate from anything less than an hour of holding the furnace in a vacuum state.

If you’re looking to get genuine leak rate information from your furnace, draw it down into a vacuum for at least one hour before you check the rate. Then, after the second hour, check the rate again. If it still appears to be higher than your target rate for optimal functionality, give the furnace another hour in vacuum and check back again. It’s important to mitigate the higher effective rate that occurred during the first hour due to outgassing by expanding your timeframe and getting a more accurate average rate measurement. Some furnace operations manuals recommend a minimum test time of four hours for this reason.

General guidelines for acceptable leak rate during vacuum furnace brazing

(per Dan Kay of Kay & Associates):

- For materials containing titanium or aluminum: The recommended leak-up rate is less than five (5) microns per hour.

- For materials containing chromium (Cr) or manganese (Mn) (but no titanium/aluminum): The acceptable leak-up rate is less than ten (10) microns per hour.

- For materials containing nickel (Ni), gold (Au), etc. (without Cr, Mn, Ti, or Al): A leak-up rate of less than fifteen (15) microns per hour is considered tolerable.

Essential Considerations for Aerospace:

- Process Sensitivity: The acceptable leak rate may need to be even lower based on the specific application and the sensitivity of the materials being processed. One common example: aluminum brazing.

- Critical Components: For components identified as highly critical for safe vehicle operation, stricter leak rate specifications may be required to ensure both reliability and safety.

For more technical reports, visit Ipsen’s Ask the Expert Archives “