SECO/WARWICK Lands 9th Furnace Order from Gas Turbine Producer

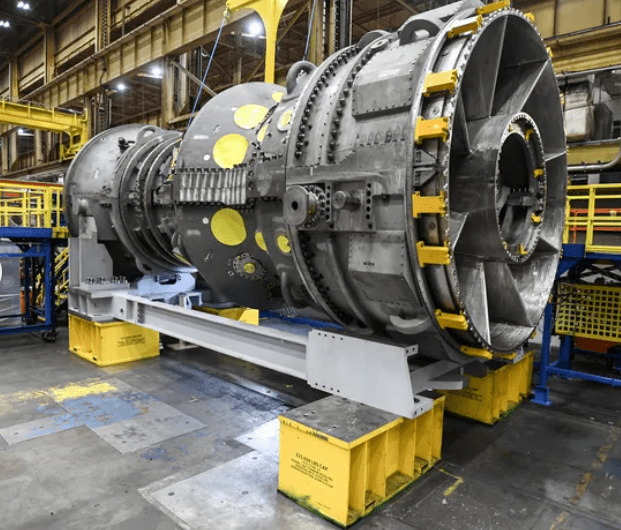

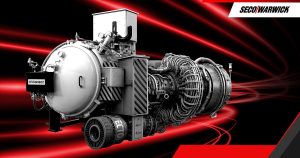

SECO/WARWICK, a world leader in heat treatment technology, has signed another contract with a Global Partner from the energy industry for the delivery of a single-chamber Vector vacuum furnace with gas cooling up to 6 bar abs. This is the ninth device delivered by SECO/WARWICK to this customer. It will be used for the production of gas turbine components.

SECO/WARWICK, a world leader in heat treatment technology, has signed another contract with a Global Partner from the energy industry for the delivery of a single-chamber Vector vacuum furnace with gas cooling up to 6 bar abs. This is the ninth device delivered by SECO/WARWICK to this customer. It will be used for the production of gas turbine components.The device is equipped with a large working space (900 x 900 x 1200 mm) and a modern system enabling rapid cooling at pressures up to 6 bar, which is crucial in the production of gas turbine components.

“This Partner is responsible for generating about 30% of the world’s electricity today, and their activities play a key role in the energy transition. Long-term cooperation with such a demanding client is a confirmation of the highest quality of our solutions, and also proof that SECO/WARWICK has a significant share in the development of modern, ecological energy technologies,” – said Maciej Korecki, Vice President of the Vacuum Segment of the SECO/WARWICK Group.”

The SECO/WARWICK equipment will support the production of components for turbines used in the most demanding operating conditions. Vector provides a high level of vacuum, thanks to an advanced pumping system; convective heating up to 850°C, improved efficiency in lower temperature ranges; the capability of using three process gases (argon, nitrogen, hydrogen); precise partial pressure control to minimize alloy losses and ensure process purity, and excellent temperature distribution thanks to additional heating elements.

“This furnace is a response to the growing production needs of the client and the requirements related to the processing of a new type of gas turbine component. Our solution will increase process efficiency while maintaining the highest quality and process purity,” – says Kamil Siedlecki, Sales Manager of SECO/WARWICK.

|

|

Did you like this article? Click here to subscribe to The Monty.

View our recent magazines and podcasts by clicking the following link. https://themonty.com/magazine/