Robots in the Heat Treatment Industry

From commercial heat treater “Wallwork Group” in the UK we have this press release about how the firm recently added robotics to a vacuum braze line at the firm’s Cambridge UK facility.

This press release prompted the team at the “Monty Heat Treat News” to contemplate robotics in the commercial heat treatment industry-the bottom line is of course that there is very little in the way of robotics and automation in the industry largely for two reasons; First is that many commercial shops are largely “job” shops meaning small volumes. Second, few manufacturers offer their heat treaters long-term contracts which makes it difficult to justify large investments in automation.

This press release prompted the team at the “Monty Heat Treat News” to contemplate robotics in the commercial heat treatment industry-the bottom line is of course that there is very little in the way of robotics and automation in the industry largely for two reasons; First is that many commercial shops are largely “job” shops meaning small volumes. Second, few manufacturers offer their heat treaters long-term contracts which makes it difficult to justify large investments in automation. There are exceptions to these rules though and over the next few days we will give you examples of a few captive and commercial heat treaters have found it advantageous to invest in robotics.

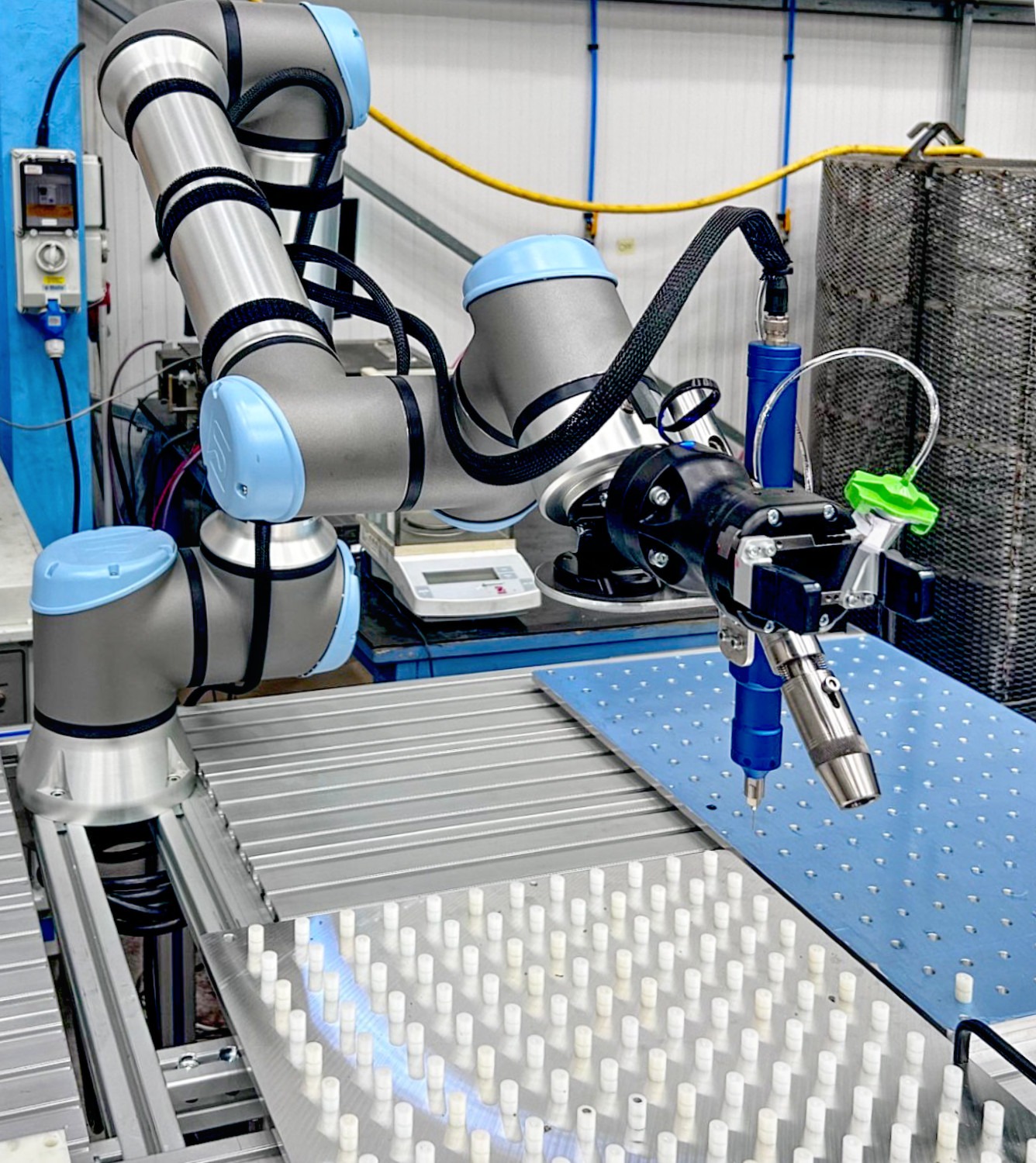

“In a £100 thousand investment, Wallwork Group has introduced a UR Cobot to their vacuum braze line in Cambridge. This will make high-volume braze components a commercially viable option for many manufacturers.

“Cost-effective, high-volume vacuum braze components have been out of reach until now. Largely due to the amount of assembly and labour time required. This investment brings the advantages of vacuum brazing to components that were previously uneconomic to process. It also means we can develop the quality of customer products,” said group director, Simeon Collins.

Chris Osborne and Odhran Mcbride of Wallwork oversaw the installation. “The medium-sized cobot is capable of manipulating a 12.5kg payload, with a 1300mm reach. It will work alongside our skilled braze operators and has the ability to learn as it goes along via a continuous improvement process. Customers will enjoy higher quality levels not seen before. Accuracy, consistency and repeatability are assured,” explained Chris.

The use of robotics also makes 24-hour braze application a reality, increasing service availability. Success with the UR Cobot is likely to spark further investment in the technology. “We are looking forward to vacuum brazing the first batch of customer components with the cobot. This is scheduled for the beginning of October,” added Odhran.

Preparing components for vacuum brazing requires great skill and attention to detail. The cobot is able to replicate this manual process. It creates complex components by joining simpler parts made from similar or dis-similar materials. A braze metal with a lower melt-point flows by capillary action into the space between the parts. The filler metal or alloy is heated to a temperature above 750ºC. This forms an exceptionally strong, sealed and leak-proof joint.

The cobot process is clean and flux-free. It produces high strength components with excellent dimensional stability. These are free of voids or inclusions, resistant to shock and vibration and able to withstand high pressures.”

Want to know more about “Wallwork Group” ? You can find a summary of the company from when “Gord Montgomery” of “The Monty” last “Visited in 2022”.

Did you like this article? Click here to subscribe to The Monty.

View our recent magazines and podcasts by clicking the following link. https://themonty.com/magazine/