Ask the Expert: Why is Graphite Felt Replacing Graphite Board in Vacuum Furnaces? By Craig Moller, Chief Engineer for Ipsen USA

Specialty insulation plays a key role in helping vacuum furnaces operate efficiently and produce consistent results. It’s one hidden component of your furnace that can make a big difference in pump down time, helps make sure your furnace can hit and hold temperature reliably every time, and protects the rest of your furnace from the intense heat inside the hot zone.

Specialty insulation plays a key role in helping vacuum furnaces operate efficiently and produce consistent results. It’s one hidden component of your furnace that can make a big difference in pump down time, helps make sure your furnace can hit and hold temperature reliably every time, and protects the rest of your furnace from the intense heat inside the hot zone.

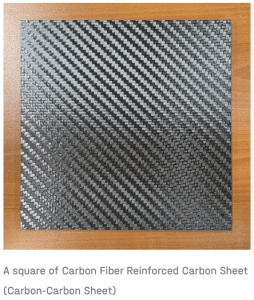

When you look at a cross-section of a graphite insulated hot zone, you might find one of two material varieties: graphite board or graphite felt. These materials are often protected with a hot face that’s made up of a graphite foil or a carbon fiber reinforced carbon sheet (also known as “carbon-carbon sheet”).

For many years, Ipsen furnace insulation cross-sections frequently contained both 1” graphite board and two ½” sections of graphite felt between the hot face and the plenum. A thin layer of graphite foil protected the hot face. The graphite foil and board worked together to serve as a rigid layer designed to resist damage from small parts that fall into the hot zone during loading and unloading.

For many years, Ipsen furnace insulation cross-sections frequently contained both 1” graphite board and two ½” sections of graphite felt between the hot face and the plenum. A thin layer of graphite foil protected the hot face. The graphite foil and board worked together to serve as a rigid layer designed to resist damage from small parts that fall into the hot zone during loading and unloading.

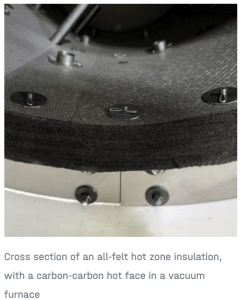

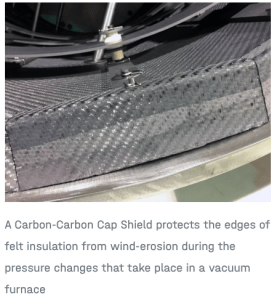

If you look at a new Ipsen vacuum furnace, you’ll notice that our standards have changed. Today’s Ipsen furnaces are offered with four ½” graphite felt layers behind a thin layer of carbon-carbon sheet hot face. A carbon-carbon cap shield can be installed at the front edge of the hot zone to prevent damage from wind erosion within certain Ipsen furnaces where needed.

If you look at a new Ipsen vacuum furnace, you’ll notice that our standards have changed. Today’s Ipsen furnaces are offered with four ½” graphite felt layers behind a thin layer of carbon-carbon sheet hot face. A carbon-carbon cap shield can be installed at the front edge of the hot zone to prevent damage from wind erosion within certain Ipsen furnaces where needed.

Furnace operators who are looking for a replacement hot zone are frequently encouraged to move to an all-felt hot zone insulation package, though a board and felt hot zone can be provided at a customer’s request. Many users have asked – why make the change?

The Case for All-Felt Insulation

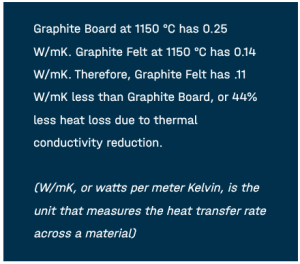

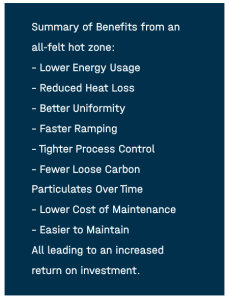

Thermal insulation works best when there is less density – lower density insulation is more effective at limiting thermal energy transfer than higher density materials. Though graphite board is designed to be porous, the larger gaps in the cloth-like material of the graphite felt significantly lowers the transfer of thermal energy by conduction. This way, the felt allows less heat flux to reach the plenum and the chamber cold wall, protecting both more effectively.

Thermal insulation works best when there is less density – lower density insulation is more effective at limiting thermal energy transfer than higher density materials. Though graphite board is designed to be porous, the larger gaps in the cloth-like material of the graphite felt significantly lowers the transfer of thermal energy by conduction. This way, the felt allows less heat flux to reach the plenum and the chamber cold wall, protecting both more effectively.

And the difference is significant. When comparing the use of a combination of board and felt to an all-felt solution, our engineers have observed that there’s roughly a 10% overall increase in heat loss for a 1” felt plus 1” board insulation design when compared to a similar setup using exclusively 2” of graphite felt.

Graphite felt also has sufficient elasticity to withstand thermal expansion and has proven to be easier to maintain. Replacing felt can be as simple as removing the carbon fiber hot face, cutting out the damaged felt with a pair of scissors or shop knife, and replacing the section with a new piece of felt cut to size. Also, it’s easier to maneuver felt around mounting points and nozzles. A handheld cutting tool allows for precise cuts around ingress points during installation. A roll of graphite felt kept on hand can be used for emergency repairs.

Graphite felt also has sufficient elasticity to withstand thermal expansion and has proven to be easier to maintain. Replacing felt can be as simple as removing the carbon fiber hot face, cutting out the damaged felt with a pair of scissors or shop knife, and replacing the section with a new piece of felt cut to size. Also, it’s easier to maneuver felt around mounting points and nozzles. A handheld cutting tool allows for precise cuts around ingress points during installation. A roll of graphite felt kept on hand can be used for emergency repairs.

Thermal expansion and contraction may occasionally cause graphite board to show cracks in certain sections. In time, those cracks may grow to a point where the board needs to be replaced. Since graphite board is a stiffer, more dense material, it needs to be carefully machined to match the piece that it’s replacing.

The woven fibers in the carbon-carbon sheet make it much more resistant to tearing and brittleness than foil, while the compressibility of the felt is better at absorbing the shock of falling parts and springing back. Boards are also more susceptible to wind erosion in the cracks and holes, having an adverse effect on the board’s longevity.

Are You Ready for a New Hot Zone?

You’ll know it’s time to consider replacing your old felt and board hot zone with a new all-felt hot zone if:

You’ll know it’s time to consider replacing your old felt and board hot zone with a new all-felt hot zone if:

- Your furnace doesn’t pump down effectively any longer

- You’re finding it difficult to hit set points that you used to hit regularly at higher temperatures

- Your steady power level has increased as compared to when the hot zone was new

- You’re seeing hot spots on the outside of your furnace

- Your furnace is failing Temperature Uniformity Surveys

- You’re seeing graphite contamination on part surfaces

- Or you’re noticing cracking and erosion of your graphite insulation boards